Podcast

Questions and Answers

垫圈的主要作用是什么?

垫圈的主要作用是什么?

齿轮传动的主要功能是什么?

齿轮传动的主要功能是什么?

斜齿轮相比直齿轮有什么优势?

斜齿轮相比直齿轮有什么优势?

使用齿轮传动的主要优点是什么?

使用齿轮传动的主要优点是什么?

Signup and view all the answers

什么是机械设计的基本原则?

什么是机械设计的基本原则?

Signup and view all the answers

行星齿轮传动有什么优点?

行星齿轮传动有什么优点?

Signup and view all the answers

机械设计主要涉及哪些领域的知识?

机械设计主要涉及哪些领域的知识?

Signup and view all the answers

下列哪一项不属于机械部件?

下列哪一项不属于机械部件?

Signup and view all the answers

螺栓和螺钉主要通过什么方式提供强度?

螺栓和螺钉主要通过什么方式提供强度?

Signup and view all the answers

下列哪种材料不太适合制作垫圈?

下列哪种材料不太适合制作垫圈?

Signup and view all the answers

设计机械系统时,需要考虑哪些基本原理?

设计机械系统时,需要考虑哪些基本原理?

Signup and view all the answers

齿轮传动是机械设计中的一个重要部分,主要用于?

齿轮传动是机械设计中的一个重要部分,主要用于?

Signup and view all the answers

Study Notes

Mechanical Design: An In-Depth Look at Components, Transmission, Principles, Elements, and Systems

Mechanical design is a fundamental aspect of engineering that involves the development of components, structures, and mechanisms to create machines capable of performing specific tasks. It necessitates a thorough understanding of various concepts such as mechanics, materials science, manufacturing processes, and performance analysis. This article delves into the world of mechanical design by exploring mechanical components, gear transmissions, design principles, machine elements, and mechanical systems.

Mechanical Components

Mechanical components serve as the building blocks for any device, system, or structure. They can range from simple bolts and screws to complex parts like cams, gears, springs, and levers. These parts are essential for transferring forces between components or converting one type of motion into another. Some common mechanical components include:

Bolts & Screws

Bolts and screws are commonly used fastening devices that provide strength through friction held together by the thread on the shank. There are several types of bolts and screws, such as hexagonal head, square head, Allen key, Robertson, Torx, and Pozidriv. Each type offers specific benefits depending on the application.

Washers

Washers are circular or rectangular flat plates made up of various materials like steel, brass, aluminum, copper, rubber, nylon, felt or leather. They serve multiple purposes including spreading loads evenly, providing additional clamping force under bolt heads, protecting softer materials from damage when using heavy duty bolts, and filling irregularities in holes.

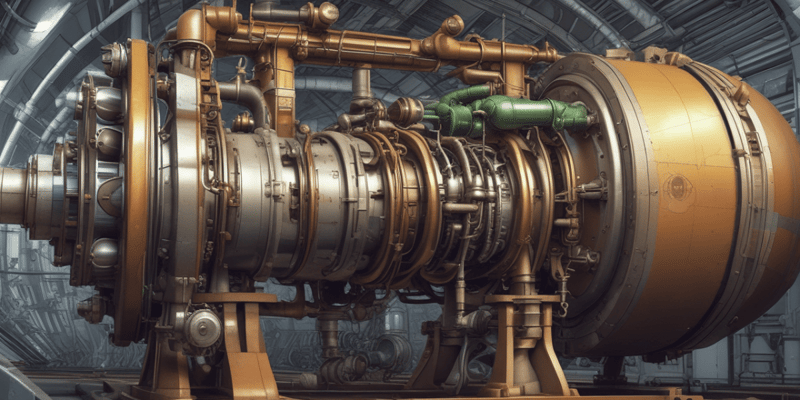

Gear Transmission

Gear transmissions play a crucial role in mechanical systems by transforming rotational motion into linear motion or changing its speed and direction. Their primary function is to transmit power efficiently between two rotating shafts while altering the output rotation rate or torque. Key aspects of gear transmissions include:

Types of Gears

There are different types of gears designed based on their shape, manufacturing process, and teeth profile:

-

Spur Gears: Used when the axes of both gears lie parallel to each other, which makes them suitable for transferring large amounts of power.

-

Helical Gears: Unlike spur gears, helical gears have inclined tooth surfaces resulting in smoother operation and reduced noise levels during rotation.

-

Bevel Gears: Employed where the axes of gears intersect creating an angle, making them efficient for turning motions around corners.

Why Use Gears?

Gear transmissions offer several advantages over direct drive mechanisms:

-

Efficiency: Gearboxes can increase efficiency due to their ability to match engine speeds with wheel speeds more closely.

-

Torque Multiplication: By changing the ratio between input and output, gears can multiply torque enabling heavier workloads.

-

Speed Reduction: Through the use of planetary gear sets, gearboxes can effectively reduce high-speed rotation to lower-speed rotation.

Mechanical Design Principles

Design principles guide engineers to create functional and robust structures. Here are some fundamental concepts:

Lever Principle

The lever principle dictates that any torque about a fulcrum will be proportional to the product of the force applied and the distance from the fulcrum. This helps in designing simple machines like pulleys, ropes, and weights.

Moments Principle

Moments principle states that the sum of moments about any axis must equal zero within a statically determinate system. It ensures equilibrium in complex structures formed by linkages, joints, rigid bodies, etc.

Frictional Forces Principle

Frictional forces play a significant role in holding objects together, whether sliding along a surface or remaining stationary. Understanding these forces allows us to design components resistant to wear and tear.

Machine Elements

Machine elements are the basic physical units of machines. They encompass all components required for assembling a functional machine. Common machine elements include bearings, cams, couplings, liners, pumps, shafts, valves, wheels, and springs. These elements work together to produce desired outputs from given inputs.

Mechanical Systems

Mechanical systems consist of assemblies of components connected via nodes. They follow certain constraints like balancing equations due to Newton's laws of motion. System behavior depends on factors like material properties, environmental conditions, load distribution, geometry, support conditions, and boundary conditions. By understanding these aspects, we can design efficient and reliable systems capable of performing diverse tasks.

In conclusion, mechanical design is a multifaceted field involving knowledge across many domains. From understanding individual components like bolts and washers to mastering intricate systems involving gears and transmissions, there are numerous facets to consider. As technology advances, so too do the possibilities for innovative designs that push the boundaries of what machines can achieve.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Explore the intricacies of mechanical design, including components like bolts and screws, gear transmissions, design principles such as lever and frictional forces, machine elements like shafts and springs, and mechanical systems. Gain insights into the fundamental concepts that drive the creation of functional machines.