Podcast

Questions and Answers

What is the primary purpose of mechanical engineering drawings?

What is the primary purpose of mechanical engineering drawings?

- To provide aesthetic guidelines for engineering projects.

- To communicate design and specifications for manufacturing. (correct)

- To eliminate the need for manufacturing processes.

- To solely visualize the design of mechanical components.

Which type of drawing displays how different components fit together?

Which type of drawing displays how different components fit together?

- Assembly Drawings (correct)

- Detail Drawings

- Pictorial Drawings

- Isometric Drawings

Which projection method places views on opposite sides of the object?

Which projection method places views on opposite sides of the object?

- Isometric Projection

- Orthographic Projection

- Third Angle Projection

- First Angle Projection (correct)

What does Geometric Dimensioning and Tolerancing (GD&T) ensure?

What does Geometric Dimensioning and Tolerancing (GD&T) ensure?

Which type of drawing is used to provide internal details by cutting through objects?

Which type of drawing is used to provide internal details by cutting through objects?

What is one best practice for creating mechanical drawings?

What is one best practice for creating mechanical drawings?

What do hidden lines in engineering drawings represent?

What do hidden lines in engineering drawings represent?

Which of the following tools is commonly used to create precise engineering drawings?

Which of the following tools is commonly used to create precise engineering drawings?

Flashcards are hidden until you start studying

Study Notes

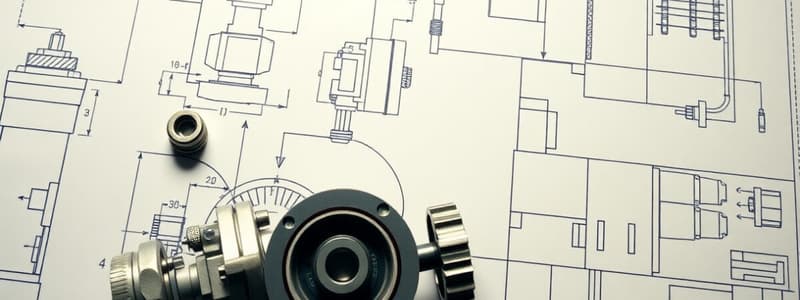

Mechanical Engineering Drawing

-

Definition: A specialized form of engineering drawing crucial for conveying information about mechanical components and assemblies.

-

Purpose:

- Communicates design and specifications effectively.

- Serves as a guide for manufacturing, assembly, and quality control.

-

Types of Drawings:

- Detail Drawings: Show all necessary views and dimensions of individual parts.

- Assembly Drawings: Illustrate how various components fit together.

- Sectional Views: Provide internal details not visible in standard views by cutting through objects.

- Isometric Drawings: 3D representations that depict components as they appear in space.

- Pictorial Drawings: Visual representations that emphasize the spatial relationships of components.

-

Projection Methods:

- Orthographic Projection: Multiple 2D views (front, top, side) to represent a 3D object.

- Third Angle Projection: Standard method in the U.S., views are placed in the quadrants of the drawing sheet.

- First Angle Projection: Common in Europe, views are placed on opposite sides of the object.

-

Drawing Standards:

- Adherence to standards such as ANSI, ISO for uniformity.

- Use of specific symbols and abbreviations to convey information clearly.

-

Dimensional and Tolerancing:

- Dimensioning: Indicate size, location, and direction of features.

- Geometric Dimensioning and Tolerancing (GD&T): Defines acceptable variations in the forms and sizes of parts, ensuring interoperability.

-

Line Conventions:

- Visible Lines: Show edges of the object.

- Hidden Lines: Represent edges not directly visible.

- Center Lines: Indicate rotational centers or symmetry.

-

Notation:

- Includes symbols for welding, machining, finishes, and materials.

-

Software Tools:

- Use of CAD (Computer-Aided Design) tools (e.g., AutoCAD, SolidWorks) for creating precise and complex drawings.

-

Best Practices:

- Maintain clarity and simplicity in drawings.

- Ensure all critical dimensions are included.

- Use annotations to provide additional notes about the design.

-

Review Process:

- Have drawings checked for accuracy and compliance with standards.

- Peer reviews often help identify potential issues before manufacturing.

Mechanical Engineering Drawing

- A specialized form of engineering drawing used to communicate design information for mechanical components and assemblies.

- Serves crucial roles in manufacturing, assembly, and quality control.

- Different types of mechanical engineering drawings include detail drawings, assembly drawings, sectional views, isometric drawings, and pictorial drawings.

- Detail Drawings show all necessary views and dimensions of individual parts.

- Assembly Drawings illustrate how various components fit together.

- Sectional Views provide internal details not visible in standard views by cutting through objects.

- Isometric Drawings are 3D representations that depict components as they appear in space.

- Pictorial Drawings are visual representations that emphasize the spatial relationships of components.

- Orthographic Projection uses multiple 2D views (front, top, side) to represent a 3D object.

- Third Angle Projection, standard in the U.S., places views in the quadrants of the drawing sheet.

- First Angle Projection, common in Europe, places views on opposite sides of the object.

- Drawing Standards ensure uniformity and clarity through adherence to standards like ANSI and ISO.

- Dimensional and Tolerancing involve dimensioning to indicate size, location, and direction of features while GD&T (Geometric Dimensioning and Tolerancing) defines acceptable variations in forms and sizes.

- Line Conventions are used to represent different elements: visible lines, hidden lines, center lines.

- Notation includes symbols for welding, machining, finishes, and materials, providing additional information.

- CAD (Computer-Aided Design) tools are essential for creating precise and complex drawings.

- Best Practices for mechanical engineering drawings include clarity, simplicity, inclusion of critical dimensions, and use of annotations for additional notes.

- Review Process ensures accuracy and compliance with standards, with peer reviews helping identify potential issues before manufacturing.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.