Podcast

Questions and Answers

What is the primary mechanism by which reciprocating engines convert chemical energy into mechanical energy?

What is the primary mechanism by which reciprocating engines convert chemical energy into mechanical energy?

Which type of engine is typically found in smaller, general aviation aircraft?

Which type of engine is typically found in smaller, general aviation aircraft?

What is a characteristic of reciprocating engines that allows for easier maintenance and repair?

What is a characteristic of reciprocating engines that allows for easier maintenance and repair?

What is the primary operating principle of turbine engines?

What is the primary operating principle of turbine engines?

Signup and view all the answers

Which type of engine is preferred for commercial airliners and military aircraft?

Which type of engine is preferred for commercial airliners and military aircraft?

Signup and view all the answers

What is a key advantage of turbine engines over reciprocating engines?

What is a key advantage of turbine engines over reciprocating engines?

Signup and view all the answers

Which type of engine is more efficient at lower speeds and altitudes?

Which type of engine is more efficient at lower speeds and altitudes?

Signup and view all the answers

What is a component found in turbine engines but not in reciprocating engines?

What is a component found in turbine engines but not in reciprocating engines?

Signup and view all the answers

Which type of engine is more complex than reciprocating engines?

Which type of engine is more complex than reciprocating engines?

Signup and view all the answers

What is the result of the combustion process in turbine engines?

What is the result of the combustion process in turbine engines?

Signup and view all the answers

Turbine engines are more efficient at lower altitudes and speeds.

Turbine engines are more efficient at lower altitudes and speeds.

Signup and view all the answers

Reciprocating engines have a lower power-to-weight ratio compared to turbine engines.

Reciprocating engines have a lower power-to-weight ratio compared to turbine engines.

Signup and view all the answers

Air is ingested and compressed by pistons in reciprocating engines.

Air is ingested and compressed by pistons in reciprocating engines.

Signup and view all the answers

Turbine engines have a simpler design than reciprocating engines.

Turbine engines have a simpler design than reciprocating engines.

Signup and view all the answers

Reciprocating engines operate on the principle of the Brayton cycle.

Reciprocating engines operate on the principle of the Brayton cycle.

Signup and view all the answers

Turbine engines are suitable for light aircraft that operate at lower altitudes.

Turbine engines are suitable for light aircraft that operate at lower altitudes.

Signup and view all the answers

Pistons are a component found only in turbine engines.

Pistons are a component found only in turbine engines.

Signup and view all the answers

Turbine engines are typically used in smaller, general aviation aircraft.

Turbine engines are typically used in smaller, general aviation aircraft.

Signup and view all the answers

The crankshaft is a component found in turbine engines.

The crankshaft is a component found in turbine engines.

Signup and view all the answers

Reciprocating engines are more reliable than turbine engines.

Reciprocating engines are more reliable than turbine engines.

Signup and view all the answers

How do reciprocating engines convert linear motion into rotational motion?

How do reciprocating engines convert linear motion into rotational motion?

Signup and view all the answers

What is the primary advantage of turbine engines over reciprocating engines in terms of operating conditions?

What is the primary advantage of turbine engines over reciprocating engines in terms of operating conditions?

Signup and view all the answers

What is the significance of the power-to-weight ratio in reciprocating engines?

What is the significance of the power-to-weight ratio in reciprocating engines?

Signup and view all the answers

How do turbine engines generate thrust?

How do turbine engines generate thrust?

Signup and view all the answers

What is the primary difference in design complexity between reciprocating and turbine engines?

What is the primary difference in design complexity between reciprocating and turbine engines?

Signup and view all the answers

In what type of aircraft are reciprocating engines typically found?

In what type of aircraft are reciprocating engines typically found?

Signup and view all the answers

What is the result of the combustion process in reciprocating engines?

What is the result of the combustion process in reciprocating engines?

Signup and view all the answers

How do turbine engines excel in terms of reliability?

How do turbine engines excel in terms of reliability?

Signup and view all the answers

What is a key advantage of reciprocating engines in terms of maintenance?

What is a key advantage of reciprocating engines in terms of maintenance?

Signup and view all the answers

How do turbine engines differ from turboprop and turboshaft engines?

How do turbine engines differ from turboprop and turboshaft engines?

Signup and view all the answers

Study Notes

Reciprocating Engines

- Also known as piston engines, they have been used in aircraft since the dawn of powered flight.

- Operate on a straightforward principle: converting linear motion of pistons into rotational torque that turns propellers.

- Function through a cycle of intake, compression, power, and exhaust.

- Common designs include:

- Flat or horizontally opposed engines

- Inline engines

- V-type engines

- Radial engines

- Each design affects an aircraft's balance, power output, and pilot's field of vision.

- Components include:

- Cylinders

- Pistons

- Crankshaft

- Spark plugs

- Valves

- Benefits include:

- High power-to-weight ratio

- Efficient operation at lower altitudes and speeds

- Simple design for easier maintenance and repair

- Typically used in smaller, general aviation aircraft due to simplicity and cost-effectiveness.

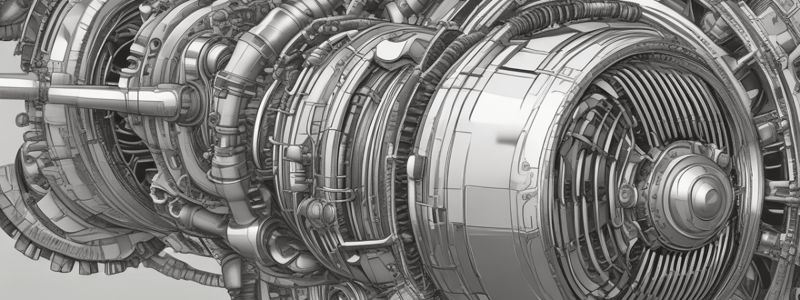

Turbine Engines

- Operate on the principle of the Brayton cycle.

- Consist of four stages: intake, compression, combustion, and exhaust.

- Air is compressed by a compressor, mixed with fuel, and ignited in the combustion chamber.

- High-pressure gases expand through a turbine, producing thrust before exiting through the exhaust nozzle.

- Types of turbine engines include:

- Turbojet engines

- Turbofan engines

- Turboprop engines

- Turboshaft engines

- Each type has unique applications and benefits:

- Turbojet: ideal for high-speed, high-altitude flight

- Turbofan: quieter and more efficient, suitable for commercial airliners

- Turboprop: efficient at lower speeds, perfect for regional transports

- Turboshaft: provides power to helicopter rotors and other applications requiring high-torque output

- Components include:

- Compressor

- Combustion chamber

- Turbine

- Exhaust nozzle

- Advantages include:

- Remarkable efficiency at high speeds and altitudes

- Reliability

- Longer lifespan

- Ability to generate significant thrust

- Technological advancements have led to:

- Use of lightweight, temperature-resistant composites

- Innovative cooling techniques

- Pushing boundaries of engine performance and efficiency

Comparison of Reciprocating and Turbine Engines

- Reciprocating engines are more efficient at lower speeds and suitable for light aircraft operating at lower altitudes.

- Turbine engines excel at high speeds and altitudes, making them ideal for airliners and jet aircraft.

- Turbine engines are more complex and have a higher power-to-weight ratio compared to reciprocating engines.

- Reciprocating engines are simpler, more cost-effective, and easier to maintain, but less efficient at high speeds and altitudes.

Reciprocating Engines

- Also known as piston engines, they have been used in aircraft since the dawn of powered flight.

- Operate on a straightforward principle: converting linear motion of pistons into rotational torque that turns propellers.

- Function through a cycle of intake, compression, power, and exhaust.

- Common designs include:

- Flat or horizontally opposed engines

- Inline engines

- V-type engines

- Radial engines

- Each design affects an aircraft's balance, power output, and pilot's field of vision.

- Components include:

- Cylinders

- Pistons

- Crankshaft

- Spark plugs

- Valves

- Benefits include:

- High power-to-weight ratio

- Efficient operation at lower altitudes and speeds

- Simple design for easier maintenance and repair

- Typically used in smaller, general aviation aircraft due to simplicity and cost-effectiveness.

Turbine Engines

- Operate on the principle of the Brayton cycle.

- Consist of four stages: intake, compression, combustion, and exhaust.

- Air is compressed by a compressor, mixed with fuel, and ignited in the combustion chamber.

- High-pressure gases expand through a turbine, producing thrust before exiting through the exhaust nozzle.

- Types of turbine engines include:

- Turbojet engines

- Turbofan engines

- Turboprop engines

- Turboshaft engines

- Each type has unique applications and benefits:

- Turbojet: ideal for high-speed, high-altitude flight

- Turbofan: quieter and more efficient, suitable for commercial airliners

- Turboprop: efficient at lower speeds, perfect for regional transports

- Turboshaft: provides power to helicopter rotors and other applications requiring high-torque output

- Components include:

- Compressor

- Combustion chamber

- Turbine

- Exhaust nozzle

- Advantages include:

- Remarkable efficiency at high speeds and altitudes

- Reliability

- Longer lifespan

- Ability to generate significant thrust

- Technological advancements have led to:

- Use of lightweight, temperature-resistant composites

- Innovative cooling techniques

- Pushing boundaries of engine performance and efficiency

Comparison of Reciprocating and Turbine Engines

- Reciprocating engines are more efficient at lower speeds and suitable for light aircraft operating at lower altitudes.

- Turbine engines excel at high speeds and altitudes, making them ideal for airliners and jet aircraft.

- Turbine engines are more complex and have a higher power-to-weight ratio compared to reciprocating engines.

- Reciprocating engines are simpler, more cost-effective, and easier to maintain, but less efficient at high speeds and altitudes.

Reciprocating Engines

- Also known as piston engines, they have been used in aircraft since the dawn of powered flight.

- Operate on a straightforward principle: converting linear motion of pistons into rotational torque that turns propellers.

- Function through a cycle of intake, compression, power, and exhaust.

- Common designs include:

- Flat or horizontally opposed engines

- Inline engines

- V-type engines

- Radial engines

- Each design affects an aircraft's balance, power output, and pilot's field of vision.

- Components include:

- Cylinders

- Pistons

- Crankshaft

- Spark plugs

- Valves

- Benefits include:

- High power-to-weight ratio

- Efficient operation at lower altitudes and speeds

- Simple design for easier maintenance and repair

- Typically used in smaller, general aviation aircraft due to simplicity and cost-effectiveness.

Turbine Engines

- Operate on the principle of the Brayton cycle.

- Consist of four stages: intake, compression, combustion, and exhaust.

- Air is compressed by a compressor, mixed with fuel, and ignited in the combustion chamber.

- High-pressure gases expand through a turbine, producing thrust before exiting through the exhaust nozzle.

- Types of turbine engines include:

- Turbojet engines

- Turbofan engines

- Turboprop engines

- Turboshaft engines

- Each type has unique applications and benefits:

- Turbojet: ideal for high-speed, high-altitude flight

- Turbofan: quieter and more efficient, suitable for commercial airliners

- Turboprop: efficient at lower speeds, perfect for regional transports

- Turboshaft: provides power to helicopter rotors and other applications requiring high-torque output

- Components include:

- Compressor

- Combustion chamber

- Turbine

- Exhaust nozzle

- Advantages include:

- Remarkable efficiency at high speeds and altitudes

- Reliability

- Longer lifespan

- Ability to generate significant thrust

- Technological advancements have led to:

- Use of lightweight, temperature-resistant composites

- Innovative cooling techniques

- Pushing boundaries of engine performance and efficiency

Comparison of Reciprocating and Turbine Engines

- Reciprocating engines are more efficient at lower speeds and suitable for light aircraft operating at lower altitudes.

- Turbine engines excel at high speeds and altitudes, making them ideal for airliners and jet aircraft.

- Turbine engines are more complex and have a higher power-to-weight ratio compared to reciprocating engines.

- Reciprocating engines are simpler, more cost-effective, and easier to maintain, but less efficient at high speeds and altitudes.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

Explore the fundamentals of aircraft engine designs, focusing on reciprocating engines, their mechanics, and importance in flight operations.