Podcast

Questions and Answers

What is the main function of the crankshaft in a reciprocating engine?

What is the main function of the crankshaft in a reciprocating engine?

- Facilitates combustion within cylinders

- Delivers fuel to the engine

- Transforms linear motion of pistons into rotary motion (correct)

- Ignites the air-fuel mixture

Which type of reciprocating engine has a compact design and a low center of gravity?

Which type of reciprocating engine has a compact design and a low center of gravity?

- Horizontally Opposed (Boxer) Engine (correct)

- V-Type Engine

- Inline Engine

- Radial Engine

During which stroke does the spark plug ignite the air-fuel mixture?

During which stroke does the spark plug ignite the air-fuel mixture?

- Exhaust Stroke

- Compression Stroke

- Intake Stroke

- Power Stroke (correct)

What is the primary disadvantage of reciprocating engines compared to turbine engines?

What is the primary disadvantage of reciprocating engines compared to turbine engines?

Which system in a reciprocating engine is critical for reducing friction between moving parts?

Which system in a reciprocating engine is critical for reducing friction between moving parts?

What is TBO (Time Between Overhaul) in relation to reciprocating engines?

What is TBO (Time Between Overhaul) in relation to reciprocating engines?

What type of stroke follows the compression stroke in a four-stroke cycle?

What type of stroke follows the compression stroke in a four-stroke cycle?

Which of the following is NOT a basic component of a reciprocating engine?

Which of the following is NOT a basic component of a reciprocating engine?

Study Notes

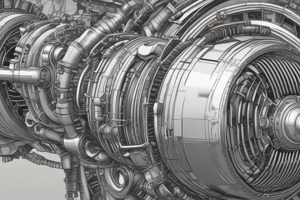

Overview of Reciprocating Engines in Aircraft

- Definition: A reciprocating engine is a type of internal combustion engine that converts fuel into mechanical energy through reciprocating motion of pistons.

Basic Components

- Cylinders: House the pistons and facilitate combustion.

- Pistons: Move up and down within cylinders; convert combustion energy into mechanical energy.

- Crankshaft: Transforms the linear motion of the pistons into rotary motion to drive the propeller.

- Valves: Control the intake of air-fuel mixture and exhaust of combustion gases (intake and exhaust valves).

- Spark Plugs: Ignite the air-fuel mixture within the combustion chamber.

- Fuel System: Delivers fuel to the engine; includes fuel tanks, pumps, and lines.

- Lubrication System: Reduces friction between moving parts; includes oil sump and oil pump.

Engine Cycle

- Four-Stroke Cycle:

- Intake Stroke: Air-fuel mixture enters the cylinder.

- Compression Stroke: Mixture is compressed by the rising piston.

- Power Stroke: Spark plug ignites the mixture, forcing the piston down.

- Exhaust Stroke: Exhaust gases are expelled as the piston moves back up.

Types of Reciprocating Engines

- Horizontally Opposed (Boxer): Compact design, low center of gravity, commonly used in light aircraft.

- Inline Engines: Cylinders arranged in a straight line; often used in larger aircraft.

- V-Type Engines: Cylinders arranged in a V shape; provides higher power-to-weight ratio.

Advantages

- Simplicity: Fewer moving parts compared to turbine engines.

- Cost-Effective: Generally lower purchase and maintenance costs.

- Reliability: Proven technology with a long history of use in general aviation.

Disadvantages

- Weight: Heavier compared to turbine engines for the same power output.

- Performance Limitations: Less efficient at high altitudes and speeds.

- Vibration: Can produce significant vibration, requiring additional mounting considerations.

Maintenance Considerations

- Regular Inspections: Essential for safety and performance; includes checking oil levels, spark plugs, and fuel systems.

- TBO (Time Between Overhaul): Specific intervals recommended for maintenance to ensure reliability.

- Fuel Quality: Use of appropriate aviation fuel (e.g., 100LL) is critical for engine performance.

Applications

- General Aviation: Widely used in small aircraft for private flying, flight training, and recreational flying.

- Experimental and Homebuilt Aircraft: Popular choice for custom-built aircraft due to versatility and ease of modification.

Overview of Reciprocating Engines in Aircraft

- A reciprocating engine transforms fuel into mechanical energy through the pistons' reciprocating motion.

Basic Components

- Cylinders: Enclose pistons; essential for combustion.

- Pistons: Ascend and descend within cylinders; change combustion energy to mechanical power.

- Crankshaft: Converts linear piston movement into rotary motion, which drives the propeller.

- Valves: Regulate air-fuel intake and exhaust gas expulsion; includes intake and exhaust valves.

- Spark Plugs: Ignite the air-fuel mixture in the combustion chamber.

- Fuel System: Comprises tanks, pumps, and lines that supply fuel to the engine.

- Lubrication System: Minimizes friction among moving parts; includes an oil sump and oil pump.

Engine Cycle

- Four-Stroke Cycle consists of:

- Intake Stroke: Air-fuel mixture enters the cylinder.

- Compression Stroke: Mixture is compressed by the moving piston.

- Power Stroke: Spark plug ignites the mixture, driving the piston down.

- Exhaust Stroke: Piston expels exhaust gases as it rises.

Types of Reciprocating Engines

- Horizontally Opposed (Boxer): Features a compact design and low center of gravity; common in light aircraft.

- Inline Engines: Have cylinders arranged in a straight line; typically used in larger aircraft.

- V-Type Engines: Arranged in a V shape, providing a higher power-to-weight ratio.

Advantages

- Simplicity: Design includes fewer moving parts compared to turbine engines.

- Cost-Effective: Generally has lower purchase and maintenance expenses.

- Reliability: Renowned technology with extensive use in general aviation.

Disadvantages

- Weight: Heavier than turbine engines for equal power output.

- Performance Limitations: Less fuel-efficient at higher altitudes and speeds.

- Vibration: Generates significant vibration, needing additional mounting solutions.

Maintenance Considerations

- Regular Inspections: Crucial for safety and performance; checks should include oil levels, spark plugs, and fuel systems.

- TBO (Time Between Overhaul): Recommended maintenance intervals to guarantee operation reliability.

- Fuel Quality: Appropriate aviation fuel usage, such as 100LL, crucial for maintaining engine performance.

Applications

- General Aviation: Predominantly used in small aircraft for private, training, and recreational flights.

- Experimental and Homebuilt Aircraft: A favored option for custom aircraft due to flexibility and modification ease.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

This quiz covers the basic components and functioning of reciprocating engines used in aircraft. Understand the definitions, engine cycles, and how each part contributes to the engine's operation. Test your knowledge on key terms and processes involved in these engines.