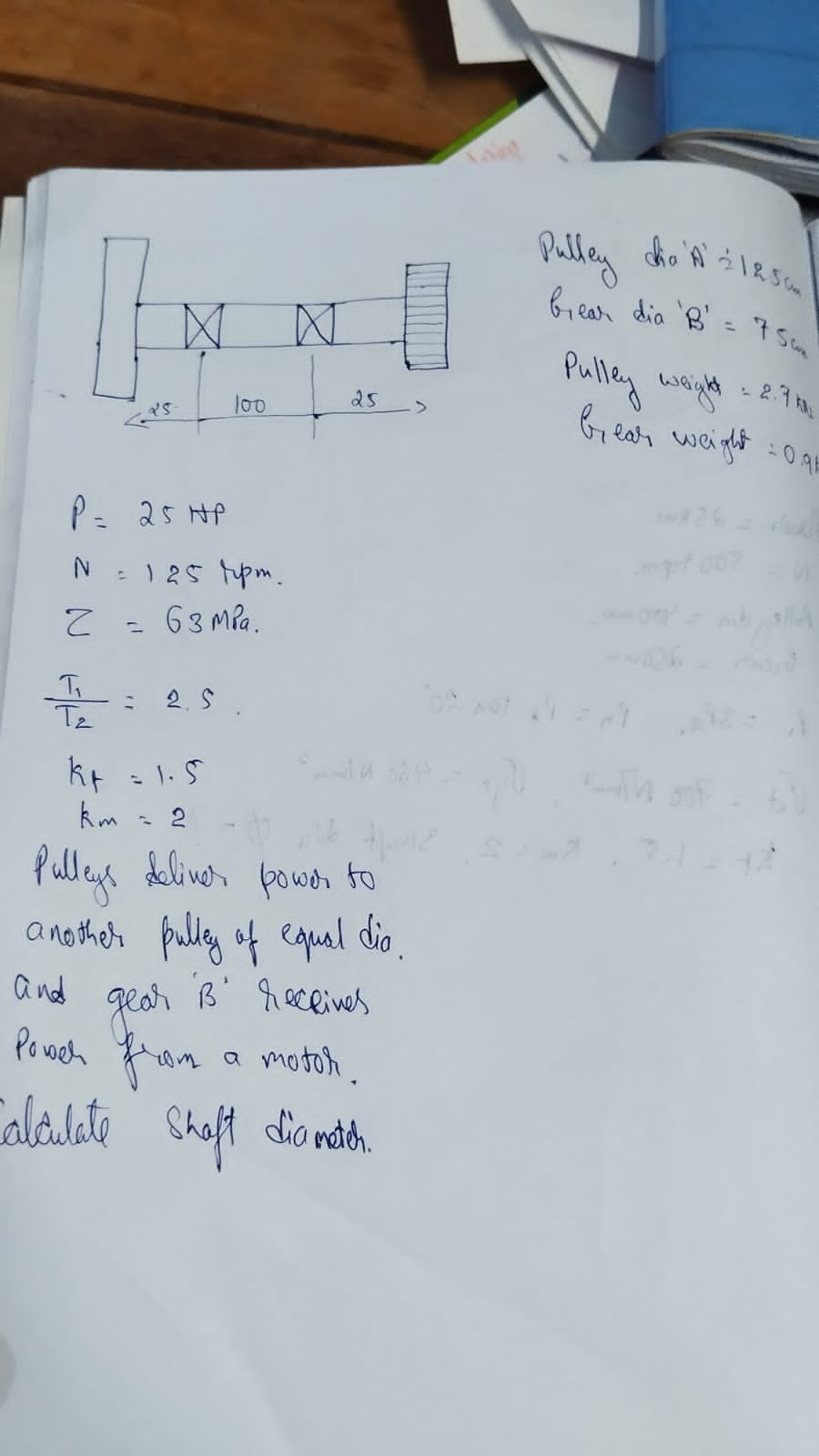

Calculate shaft diameter.

Understand the Problem

The question asks to calculate the shaft diameter given various parameters related to pulleys and gears, including power, speed, and material properties.

Answer

The shaft diameter is approximately $d \approx 94 \, \text{mm}$.

Answer for screen readers

The shaft diameter is (d \approx 94 , \text{mm}).

Steps to Solve

- Convert Power to Watts

First, convert the power from horsepower to watts because the other parameters are in metric units.

[ P = 25 , \text{HP} \times 745.7 , \text{W/HP} = 18642.5 , \text{W} ]

- Calculate Torque

Use the relationship between power, torque, and speed. The formula is:

[ P = \frac{T \times N}{9.549} ]

Where:

- (P) is in watts,

- (T) is torque in Nm,

- (N) is speed in rpm.

Rearranging gives us:

[ T = \frac{P \times 9.549}{N} ]

Substituting the values:

[ T = \frac{18642.5 , \text{W} \times 9.549}{125 , \text{rpm}} = 1415.028 , \text{Nm} ]

- Calculate Design Torque with Safety Factors

Using the given gear ratio and safety factors:

[ T_{\text{design}} = T \times \left( \frac{T_1}{T_2} \times k_f \times k_m \right) ]

Substituting the values:

[ T_{\text{design}} = 1415.028 , \text{Nm} \times \left( 2.5 \times 1.5 \times 2 \right) = 1415.028 , \text{Nm} \times 7.5 = 10613.71 , \text{Nm} ]

- Calculate Shaft Diameter

To find the diameter, use the formula for shear stress. First, rearrange for the diameter:

[ \sigma = \frac{T}{\frac{\pi}{16} \times d^3} ]

Where:

- $\sigma$ = allowable shear stress = 63 MPa = $63 \times 10^6$ Pa,

- $T$ = design torque.

Rearranging gives:

[ d^3 = \frac{16T}{\pi \sigma} ]

Substituting the values into the formula:

[ d^3 = \frac{16 \times 10613.71 , \text{Nm}}{\pi \times (63 \times 10^6 , \text{Pa})} ]

Calculating this yields:

[ d^3 = 8.4984 \times 10^{-4} , \text{m}^3 ]

Taking the cube root gives:

[ d = \sqrt[3]{8.4984 \times 10^{-4}} \approx 0.094 , \text{m} \approx 94 , \text{mm} ]

The shaft diameter is (d \approx 94 , \text{mm}).

More Information

This calculation uses safety factors and considers the torque that the shaft must handle based on the applied power and speed. The diameter ensures that the shaft can withstand shear stress without failing.

Tips

- Neglecting to convert units consistently (e.g., horsepower to watts).

- Not considering the safety factors when calculating the design torque.

- Misapplication of shear stress formulas.