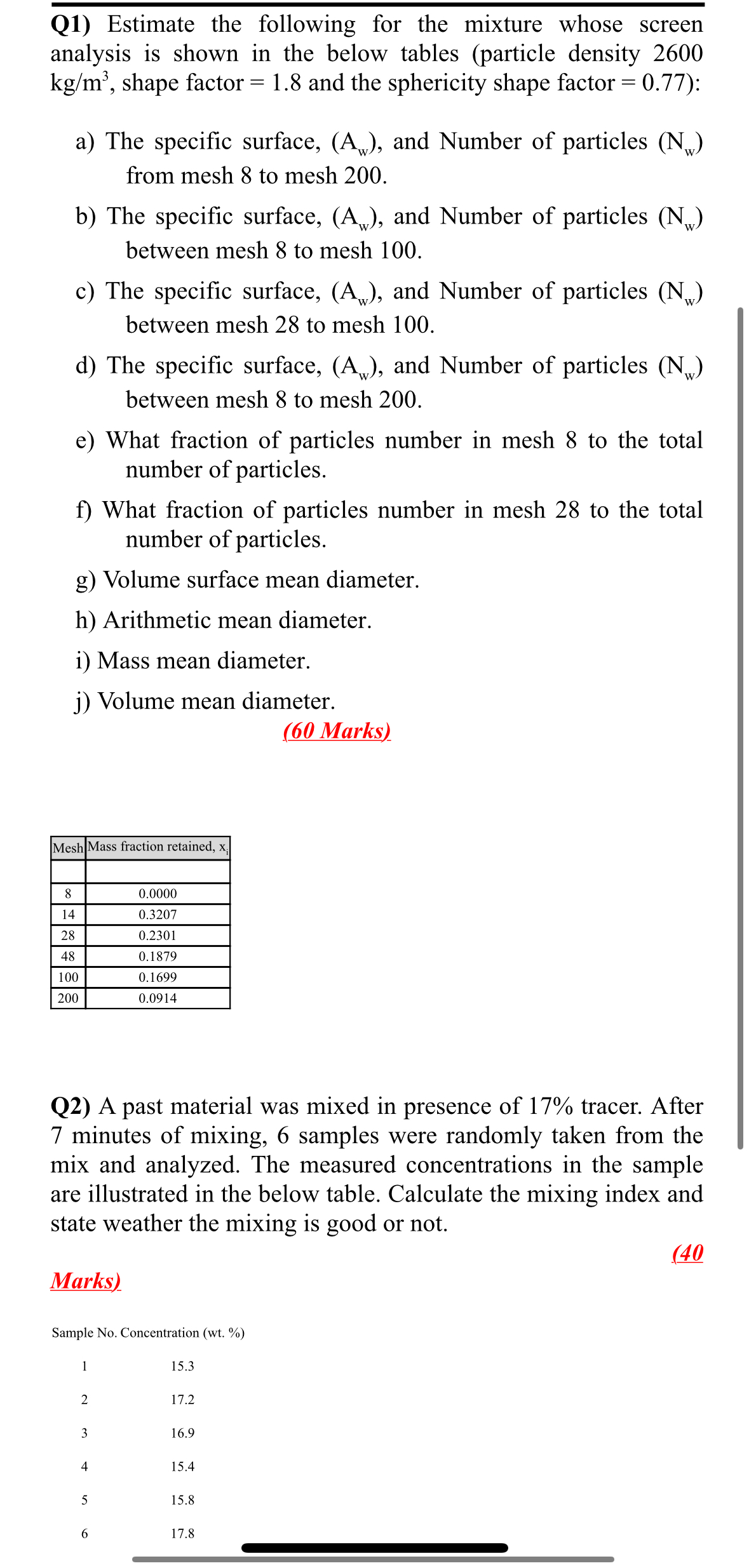

1. Estimate the following for the mixture whose screen analysis is shown in the tables: a) Specific surface (Aw) and Number of particles (Nw) from mesh 8 to mesh 200. b) Specific s... 1. Estimate the following for the mixture whose screen analysis is shown in the tables: a) Specific surface (Aw) and Number of particles (Nw) from mesh 8 to mesh 200. b) Specific surface (Aw) and Number of particles (Nw) from mesh 8 to mesh 100. c) Specific surface (Aw) and Number of particles (Nw) from mesh 28 to mesh 100. d) Specific surface (Aw) and Number of particles (Nw) from mesh 8 to mesh 200. e) Fraction of particles number in mesh 8 to total number. f) Fraction of particles number in mesh 28 to total number. g) Volume surface mean diameter. h) Arithmetic mean diameter. i) Mass mean diameter. j) Volume mean diameter. 2. Calculate the mixing index and state whether the mixing is good or not based on measured concentrations from six samples.

Understand the Problem

The questions are asking for estimations and calculations related to particle analysis and mixing efficiency using provided data. This involves determining specific surfaces, particle counts, diameters, and a mixing index based on tracer concentration from given tables.

Answer

Calculate specific surface area \( A_w \) and number of particles \( N_w \) using mesh sizes, then evaluate the mixing index to determine the mixing quality.

Answer for screen readers

- Specific surface area calculations will yield specific values for different mesh sizes as per the computation.

- The mixing index calculation will determine if the mixing is good or not based on the concentration samples.

Steps to Solve

- Calculating Specific Surface Area ( A_w ) and Number of Particles ( N_w ) from Mesh 8 to 200

To calculate the specific surface area and number of particles, use the mass fraction data provided. For a given mesh size, the specific surface area can be calculated using:

$$ A_w = \frac{6 \cdot x}{\rho \cdot d} $$

where ( x ) is the mass fraction, ( \rho ) is the density (2600 kg/m³), and ( d ) is the diameter of the particle in meters, which can be calculated from the mesh size.

- Mesh Size and Diameter Calculation

The diameter of the particles can be estimated from mesh size. The diameter corresponding to the mesh size is given by the following formula, where ( d ) is the diameter and ( mesh ) is the mesh number:

$$ d (m) = \frac{25.4}{mesh} $$

Calculate ( d ) for Mesh 8, 14, 28, 48, 100, and 200.

- Repeating Calculations for Required Mesh Sizes

Repeat calculations for:

- From mesh 8 to 100

- From mesh 28 to 100

- From mesh 8 to 200

Remember to update your values for ( x ) and the diameter ( d ).

- Estimating Particle Count ( N_w )

To estimate the number of particles, use:

$$ N_w = \frac{mass}{\text{volume of a single particle}} $$

where volume can be found using:

$$ V_p = \frac{\pi d^3}{6} $$

- Calculating Fraction of Particle Counts

To find the fraction of particle numbers in mesh 8 and 28, divide the number of particles in each mesh by the total number of particles calculated from mesh 8 to 200.

- Mean Diameters Calculation

For the following diameters:

- Volume surface mean diameter ( d_{v} )

- Arithmetic mean diameter ( d_a )

- Mass mean diameter ( d_m )

- Volume mean diameter ( d_v )

You can derive these using the following equations, where ( N ) is the total number of particles:

-

Volume surface mean diameter: $$ d_{v} = \frac{\sum{x_i \cdot d_i^3}}{\sum{x_i \cdot d_i^2}} $$

-

Arithmetic mean diameter: $$ d_a = \frac{\sum{d_i}}{N} $$

-

Mass mean diameter: $$ d_m = \frac{\sum{x_i \cdot d_i}}{\sum{x_i}} $$

- Calculating Mixing Index from Sample Analyses

For Q2, calculate the mixing index with the formula:

$$ Mixing, Index = 1 - \frac{\sum{(C_i - C_{avg})^2}}{n \cdot \sigma^2} $$

where ( C_{avg} ) is the mean of the samples and ( \sigma^2 ) is the variance.

- Final Evaluation of Mixing Goodness

Once the index is calculated, compare it against a threshold to determine if mixing is good (typically, a mixing index closer to 1 indicates good mixing).

- Specific surface area calculations will yield specific values for different mesh sizes as per the computation.

- The mixing index calculation will determine if the mixing is good or not based on the concentration samples.

More Information

Estimating specific surface areas and particle counts is critical in industries where particle analysis directly impacts quality control. The mixing index helps in assessing the uniformity of mixtures which is essential in chemical processing.

Tips

- Failing to convert mesh sizes to diameters correctly.

- Miscalculating the mass fraction retained when analyzing particle counts.

- Not checking units consistently across calculations.

AI-generated content may contain errors. Please verify critical information