Podcast

Questions and Answers

What is the primary purpose of safety glasses?

What is the primary purpose of safety glasses?

Which statement best describes the function of an on-load tap-changer?

Which statement best describes the function of an on-load tap-changer?

What type of clothing is described as having low tearing strength and tight sleeves?

What type of clothing is described as having low tearing strength and tight sleeves?

Which personal protective equipment is specifically designed to protect against falling heavy objects?

Which personal protective equipment is specifically designed to protect against falling heavy objects?

Signup and view all the answers

What is the role of a hard hat as personal protective equipment?

What is the role of a hard hat as personal protective equipment?

Signup and view all the answers

Which of the following is NOT a purpose of hearing protection?

Which of the following is NOT a purpose of hearing protection?

Signup and view all the answers

What hazards do protective gloves primarily guard against?

What hazards do protective gloves primarily guard against?

Signup and view all the answers

Select the component that allows for voltage adjustment in transformers while under load.

Select the component that allows for voltage adjustment in transformers while under load.

Signup and view all the answers

What is the primary function of the MPreC® pressure relief device?

What is the primary function of the MPreC® pressure relief device?

Signup and view all the answers

Which component is monitored by the tap-change supervisory device?

Which component is monitored by the tap-change supervisory device?

Signup and view all the answers

What role does the bevel gear play in the on-load tap-changer system?

What role does the bevel gear play in the on-load tap-changer system?

Signup and view all the answers

What does the temperature monitoring system specifically track?

What does the temperature monitoring system specifically track?

Signup and view all the answers

In the context of the drive shaft, what is the relationship of the bevel gear?

In the context of the drive shaft, what is the relationship of the bevel gear?

Signup and view all the answers

Which standard does the on-load tap-changer meet concerning pressure relief devices?

Which standard does the on-load tap-changer meet concerning pressure relief devices?

Signup and view all the answers

What is NOT a function of the drive shaft in the system?

What is NOT a function of the drive shaft in the system?

Signup and view all the answers

The tap-change supervisory device is responsible for monitoring which particular aspect of the tap changer?

The tap-change supervisory device is responsible for monitoring which particular aspect of the tap changer?

Signup and view all the answers

What is the minimum length (V1 min) required for the drive shaft with cardan joints without an insulator, in the middle of the hand crank to the middle of the bevel gear?

What is the minimum length (V1 min) required for the drive shaft with cardan joints without an insulator, in the middle of the hand crank to the middle of the bevel gear?

Signup and view all the answers

Which configuration allows for an intermediate bearing when the V1 dimension is greater than 2564 mm?

Which configuration allows for an intermediate bearing when the V1 dimension is greater than 2564 mm?

Signup and view all the answers

What is the maximum permissible axial offset for the drive shaft configuration without an insulator?

What is the maximum permissible axial offset for the drive shaft configuration without an insulator?

Signup and view all the answers

For the drive shaft configuration with an insulator, what is the minimum length (V1 min) required?

For the drive shaft configuration with an insulator, what is the minimum length (V1 min) required?

Signup and view all the answers

What is the primary function of the OF 100 oil filter unit?

What is the primary function of the OF 100 oil filter unit?

Signup and view all the answers

What is the minimum length (V1 min) needed for a drive shaft with cardan joints when the configuration exceeds 2772 mm?

What is the minimum length (V1 min) needed for a drive shaft with cardan joints when the configuration exceeds 2772 mm?

Signup and view all the answers

Which model of the drive shaft configuration does not include an insulator?

Which model of the drive shaft configuration does not include an insulator?

Signup and view all the answers

What configuration is indicated for a V1 length greater than 2772 mm?

What configuration is indicated for a V1 length greater than 2772 mm?

Signup and view all the answers

What should be avoided when the transformer is switched on to ensure safety?

What should be avoided when the transformer is switched on to ensure safety?

Signup and view all the answers

In case of a tripping motor protective switch, what is the recommended action?

In case of a tripping motor protective switch, what is the recommended action?

Signup and view all the answers

What action should be taken if the fill level of insulating fluid is below the minimum?

What action should be taken if the fill level of insulating fluid is below the minimum?

Signup and view all the answers

Which symptom indicates that the on-load tap-changer may not be functioning correctly?

Which symptom indicates that the on-load tap-changer may not be functioning correctly?

Signup and view all the answers

What regular checks should be performed on the on-load tap-changer?

What regular checks should be performed on the on-load tap-changer?

Signup and view all the answers

If the fill level falls below limit values, what should also be done?

If the fill level falls below limit values, what should also be done?

Signup and view all the answers

What should be done if the raise and lower keys of the on-load tap-changer are not functioning?

What should be done if the raise and lower keys of the on-load tap-changer are not functioning?

Signup and view all the answers

What indicates that there might be a leak in the insulating fluid system?

What indicates that there might be a leak in the insulating fluid system?

Signup and view all the answers

What is essential for the compatibility of an on-load tap-changer and its accessories?

What is essential for the compatibility of an on-load tap-changer and its accessories?

Signup and view all the answers

What information can be found on the nameplate of the on-load tap-changer?

What information can be found on the nameplate of the on-load tap-changer?

Signup and view all the answers

In which frequency range is the on-load tap-changer designed to operate?

In which frequency range is the on-load tap-changer designed to operate?

Signup and view all the answers

What should be ensured about the personnel performing work on the equipment?

What should be ensured about the personnel performing work on the equipment?

Signup and view all the answers

What is the consequence of exceeding the rated step voltage Uir?

What is the consequence of exceeding the rated step voltage Uir?

Signup and view all the answers

What should be followed when operating the product?

What should be followed when operating the product?

Signup and view all the answers

What specific aspect of electrical conditions must be observed during operation?

What specific aspect of electrical conditions must be observed during operation?

Signup and view all the answers

Which of the following is NOT a requirement for using the equipment?

Which of the following is NOT a requirement for using the equipment?

Signup and view all the answers

The signal word 'CAUTION' indicates a situation that could result in death or serious injury.

The signal word 'CAUTION' indicates a situation that could result in death or serious injury.

Signup and view all the answers

Embedded warnings provide instructions for avoiding dangerous situations in general sections.

Embedded warnings provide instructions for avoiding dangerous situations in general sections.

Signup and view all the answers

The signal word 'NOTICE' is used to indicate a situation that may lead to serious injury or death.

The signal word 'NOTICE' is used to indicate a situation that may lead to serious injury or death.

Signup and view all the answers

A warning that includes 'DANGER' signifies a hazardous situation that, if not avoided, will result in death or serious injury.

A warning that includes 'DANGER' signifies a hazardous situation that, if not avoided, will result in death or serious injury.

Signup and view all the answers

Warnings that relate to sections use a different format from those that provide embedded warnings.

Warnings that relate to sections use a different format from those that provide embedded warnings.

Signup and view all the answers

In a warning, the type of danger is typically mentioned after the action to be taken.

In a warning, the type of danger is typically mentioned after the action to be taken.

Signup and view all the answers

The oil compartment of the on-load tap-changer is partially filled with insulation fluid.

The oil compartment of the on-load tap-changer is partially filled with insulation fluid.

Signup and view all the answers

It is safe to operate the motor-drive unit with the hand crank when the transformer is energized.

It is safe to operate the motor-drive unit with the hand crank when the transformer is energized.

Signup and view all the answers

Inrush current impulses can be lower than the transformer rated current.

Inrush current impulses can be lower than the transformer rated current.

Signup and view all the answers

The hand crank can be used to complete a tap-change operation that has begun electrically.

The hand crank can be used to complete a tap-change operation that has begun electrically.

Signup and view all the answers

All stop-cocks between the on-load tap-changer and oil conservator must be closed before operation.

All stop-cocks between the on-load tap-changer and oil conservator must be closed before operation.

Signup and view all the answers

If the hand crank is difficult to move, it is recommended to continue using it until it operates smoothly.

If the hand crank is difficult to move, it is recommended to continue using it until it operates smoothly.

Signup and view all the answers

Only tap-change operations under load conditions can be performed while inrush current impulses are prevalent.

Only tap-change operations under load conditions can be performed while inrush current impulses are prevalent.

Signup and view all the answers

The use of the hand crank requires that the direction of rotation be reversed periodically.

The use of the hand crank requires that the direction of rotation be reversed periodically.

Signup and view all the answers

Manual operation of the motor-drive unit is prohibited during any maintenance tasks.

Manual operation of the motor-drive unit is prohibited during any maintenance tasks.

Signup and view all the answers

Operating the motor-drive unit with the hand crank is essential during normal operation.

Operating the motor-drive unit with the hand crank is essential during normal operation.

Signup and view all the answers

An emergency operation is defined as a tap-change operation necessary while a transformer is energized and a fault is present in the motor-drive unit.

An emergency operation is defined as a tap-change operation necessary while a transformer is energized and a fault is present in the motor-drive unit.

Signup and view all the answers

The pipe connection S can be used to completely empty the on-load tap-changer when fitted with an oil suction pipe.

The pipe connection S can be used to completely empty the on-load tap-changer when fitted with an oil suction pipe.

Signup and view all the answers

The hand crank for the motor-drive unit should only be used when the transformer is fully energized.

The hand crank for the motor-drive unit should only be used when the transformer is fully energized.

Signup and view all the answers

It is recommended to contact the Technical Service department only if there is a fault detected in the motor-drive unit.

It is recommended to contact the Technical Service department only if there is a fault detected in the motor-drive unit.

Signup and view all the answers

Pipe connection R cannot be interchanged with pipe connection Q.

Pipe connection R cannot be interchanged with pipe connection Q.

Signup and view all the answers

Normal operation of the motor-drive unit requires frequent manual intervention using the hand crank.

Normal operation of the motor-drive unit requires frequent manual intervention using the hand crank.

Signup and view all the answers

Pipe connection E2 is intended for connecting the on-load tap-changer's oil conservator.

Pipe connection E2 is intended for connecting the on-load tap-changer's oil conservator.

Signup and view all the answers

The vent screw on pipe connection S is used to facilitate drainage operations.

The vent screw on pipe connection S is used to facilitate drainage operations.

Signup and view all the answers

The operation of the motor-drive unit is allowed if the previous tap-change has not been completed correctly.

The operation of the motor-drive unit is allowed if the previous tap-change has not been completed correctly.

Signup and view all the answers

Accessing the protective housing door is necessary to make any manual changes to the motor-drive unit.

Accessing the protective housing door is necessary to make any manual changes to the motor-drive unit.

Signup and view all the answers

Only the pipe connections S and Q should be used for attaching the protective relay.

Only the pipe connections S and Q should be used for attaching the protective relay.

Signup and view all the answers

The pipe connection Q is equipped with a vent screw for pressure regulation.

The pipe connection Q is equipped with a vent screw for pressure regulation.

Signup and view all the answers

The functions of the R and Q pipe connections can be interchanged based on the configurations.

The functions of the R and Q pipe connections can be interchanged based on the configurations.

Signup and view all the answers

The blank cover on pipe connection Q is solely for the routing of connection cables.

The blank cover on pipe connection Q is solely for the routing of connection cables.

Signup and view all the answers

The transformer can be safely energized without inspection if the protective relay trips.

The transformer can be safely energized without inspection if the protective relay trips.

Signup and view all the answers

Condensate in the protective housing of the motor-drive unit can lead to damage.

Condensate in the protective housing of the motor-drive unit can lead to damage.

Signup and view all the answers

If a fault on the on-load tap-changer cannot be easily corrected, the authorized representative should not be informed.

If a fault on the on-load tap-changer cannot be easily corrected, the authorized representative should not be informed.

Signup and view all the answers

A sufficient amount of desiccant can be used in the motor-drive unit during transportation to prevent damage.

A sufficient amount of desiccant can be used in the motor-drive unit during transportation to prevent damage.

Signup and view all the answers

The on-load tap-changer should always be re-energized immediately after a protective device has tripped.

The on-load tap-changer should always be re-energized immediately after a protective device has tripped.

Signup and view all the answers

Operating instructions for protective devices are unnecessary when troubleshooting faults onsite.

Operating instructions for protective devices are unnecessary when troubleshooting faults onsite.

Signup and view all the answers

Operation interruptions lasting more than 2 weeks do not require any special actions regarding the anti-condensation heater.

Operation interruptions lasting more than 2 weeks do not require any special actions regarding the anti-condensation heater.

Signup and view all the answers

Tripping of the protective relay or other protective devices may indicate potential damage to the transformer.

Tripping of the protective relay or other protective devices may indicate potential damage to the transformer.

Signup and view all the answers

Study Notes

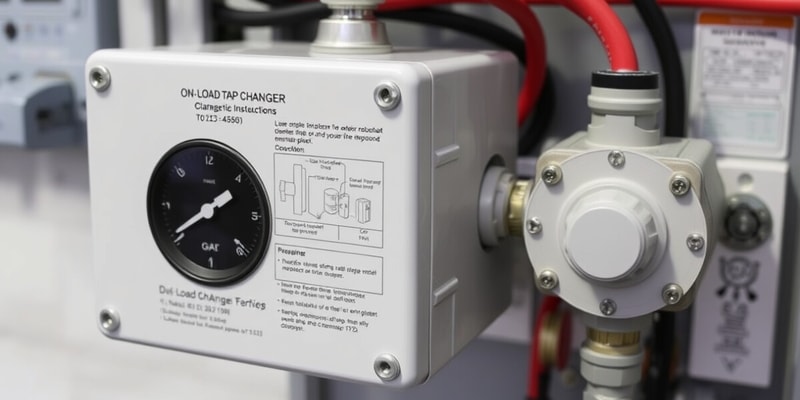

On-Load Tap-Changer Overview

- Serial numbers of on-load tap-changer and accessories must match for a single order.

- The product's standard and year of issue are indicated on the nameplate.

- Operate according to the technical file, delivery conditions, and technical data.

- Ensure all work is performed by qualified personnel only.

Electrical Operating Conditions

- Designed for 50/60 Hz sinusoidal alternating current, can switch twice the rated current at the rated step voltage.

- Short-term exceedance of rated step voltage by up to 10% is allowed without exceeding the rated step capacity.

Personal Protective Equipment (PPE)

- Close-fitting clothing, safety shoes, safety glasses, visors, hard hats, hearing protection, and protective gloves are necessary to avoid various hazards during operation.

Function of On-Load Tap-Changer

- Adjusts transformer transmission ratio without interrupting load flow.

- Compensates for voltage fluctuations in the power transmission grid.

- Integrated into transformers and connected to their active parts.

Pressure Relief Device (MPreC®)

- Available upon request and replaces rupture disk, responding to defined overpressure in the oil compartment.

- Complies with IEC 60214-1 standards for pressure relief devices.

Monitoring Systems

- The tap-change supervisory device monitors drive shaft and diverter switch operation.

- Temperature monitoring system tracks the insulating fluid temperature in the oil compartment.

Drive Shaft Function

- Connects the drive to the on-load tap-changer; changes direction from vertical to horizontal via bevel gear.

- Vertical drive shaft for connection from drive to bevel gear; horizontal shaft connects bevel gear to the tap-changer.

Drive Shaft Configurations

- Different configurations based on length and whether intermediate bearings are used; minimum lengths specified for various setups.

OF 100 Oil Filter Unit

- Cleans insulating fluid using a paper filter and combined filter insert.

- Manual operation during transformer activation is prohibited; checks on tap-changer and transformer are essential after tripping events.

Maintenance and Fault Elimination

- If tripping occurs, measurements and checks on the transformer are required; MR should be contacted for on-load tap-changer evaluations.

- Signals for low insulating fluid levels should be addressed by examining the pipe system for leaks and ensuring fluid quality.

Warnings and Safety Information

- Warnings are formatted to specify the type of danger, its source, and the recommended actions.

- Embedded warnings address specific portions within sections, providing direct instructions to avoid dangerous situations.

- Signal words convey the severity of hazards:

- DANGER: Imminent death or serious injury if not avoided.

- WARNING: Potential for death or serious injury if not avoided.

- CAUTION: Risk of minor or moderate injury if not avoided.

- NOTICE: Measures required to prevent property damage.

Product Description and Pipe Connections

- Pipe connections may include factory-fitted pipe bends which are freely swiveled when pressure rings are loosened.

- Pipe Connection Q: Closed with a blank cover; can route connection cables for supervisory devices or connect oil filter units; functions can be interchanged with Pipe R.

- Pipe Connection S: Features a vent screw; connects to drain valves and allows complete emptying of the oil from the on-load tap-changer.

- Pipe Connection R: Used for protective relay attachment and oil conservator connection; interchangeable with Pipe Q.

- Pipe Connection E2: Sealed with a blank cover; oil compartment filled with insulation fluid and all stop-cocks open.

- Tap-change operations should only be conducted after inrush current impulses have subsided to avoid overload.

Operating the Motor-Drive Unit

-

Warning of Explosion: Unauthorized operation with the hand crank can lead to death or serious injury. Follow strict guidelines for operation:

- Disconnect transformer before operation, especially with potential faults.

- Avoid using the hand crank to finish incomplete electrical tap-change operations.

- Stop using the hand crank if facing difficulty in movement and never reverse its rotation.

- Normal operation rarely requires the hand crank; it is primarily for installation or testing.

- Emergency operations must adhere to safety warnings if absolutely necessary while the transformer is energized.

Maintenance and Fault Rectification

- If protective relays or devices trip, inspect the on-load tap-changer and transformer before re-energizing.

- Maintain protective housing tightly closed to avoid moisture damage to the motor-drive unit.

- Use anti-condensation heaters during prolonged inactivity; employ desiccants if necessary.

- For unresolved faults or trips in protective devices, contact authorized representatives or the manufacturer for assistance.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Test your knowledge about on-load tap-changers and their accessories, including standard specifications and compatibility requirements. This quiz will cover important technical aspects and operating procedures. Get ready to demonstrate your expertise in this specialized area.