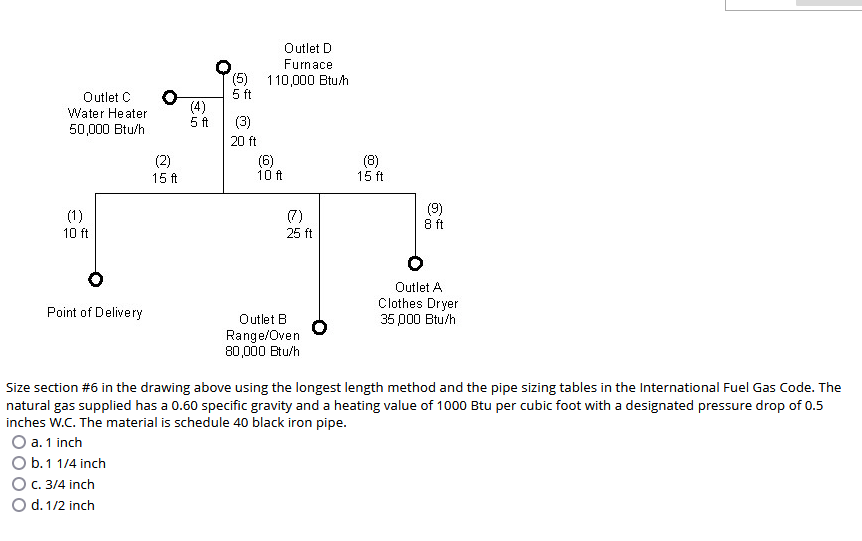

Size section #6 in the drawing above using the longest length method and the pipe sizing tables in the International Fuel Gas Code. The natural gas supplied has a 0.60 specific gra... Size section #6 in the drawing above using the longest length method and the pipe sizing tables in the International Fuel Gas Code. The natural gas supplied has a 0.60 specific gravity and a heating value of 1000 Btu per cubic foot with a designated pressure drop of 0.5 inches W.C. The material is schedule 40 black iron pipe.

Understand the Problem

The question is asking to determine the appropriate pipe size for a gas delivery system using the longest length method based on specified conditions such as gas supply specifics, heating value, pressure drop, and outlet requirements. The high-level approach involves calculating the total length of the piping system and consulting the appropriate sizing tables from the International Fuel Gas Code.

Answer

The appropriate pipe size is $1 \frac{1}{4}$ inch.

Answer for screen readers

The appropriate pipe size is $1 \frac{1}{4}$ inch.

Steps to Solve

- Determine the Total Demand for Gas

Calculate the total gas demand by adding up the Btu/h for all outlets connected to the system:

- Outlet C (Water Heater): 50,000 Btu/h

- Outlet D (Furnace): 110,000 Btu/h

- Outlet B (Range/Oven): 80,000 Btu/h

- Outlet A (Clothes Dryer): 35,000 Btu/h

Total demand: $$ \text{Total Demand} = 50,000 + 110,000 + 80,000 + 35,000 = 275,000 \text{ Btu/h} $$

- Calculate the Total Length of the Piping System

Identify the length of the pipe runs from the point of delivery to each outlet:

- To Outlet D: 20 ft + 5 ft + 10 ft = 35 ft

- To Outlet C: 15 ft + 5 ft = 20 ft

- To Outlet B: 25 ft

- To Outlet A: 8 ft + 15 ft = 23 ft

The longest run is to Outlet D at 35 ft.

- Determine the Equivalent Length of Fittings

Convert fittings to feet using equivalents for the given pipe size:

- Assume 2 elbows (2 ft each), 1 tee (4 ft), 1 valve (2 ft). The total equivalent_length: $$ \text{Fittings Length} = (2 \cdot 2) + 4 + 2 = 10 \text{ ft} $$

- Calculate the Total Equivalent Length

Add the length of the longest pipe run to the equivalent lengths of fittings: $$ \text{Total Equivalent Length} = 35 \text{ ft (longest run)} + 10 \text{ ft (fittings)} = 45 \text{ ft} $$

- Refer to the Sizing Tables from the International Fuel Gas Code

Use the total length and gas demand to check the sizing table for schedule 40 black iron pipe with a pressure drop of 0.5 inches W.C. and a heater value of 1000 Btu/cubic foot.

Refer to the table and locate the row for 275,000 Btu/h and a total run of approximately 45 ft.

- Determine the Pipe Size Based on Sizing Tables

Based on the data from the tables, the appropriate pipe size for the determined total demand and equivalent length will be selected from the provided options:

- a. 1 inch

- b. 1 1/4 inch

- c. 3/4 inch

- d. 1/2 inch

The appropriate pipe size is $1 \frac{1}{4}$ inch.

More Information

This calculation is crucial in ensuring proper gas flow and maintaining safety in the gas delivery system. Sizing the pipe correctly minimizes pressure drop and ensures efficient operation of appliances.

Tips

- Failing to include the equivalent lengths of fittings which can lead to underestimating the total length.

- Not checking the correct row/column in the sizing tables leading to incorrect pipe size selection.

AI-generated content may contain errors. Please verify critical information