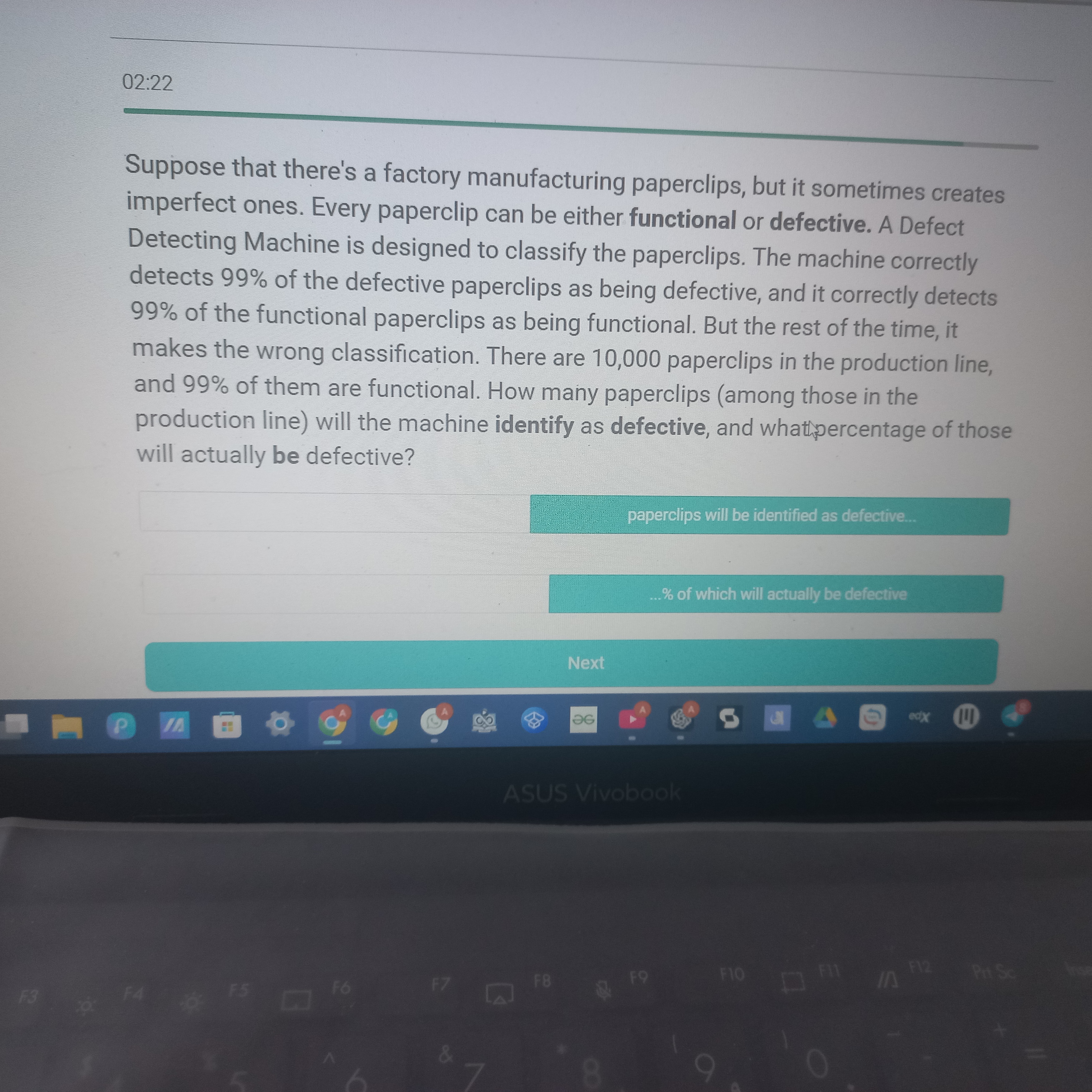

How many paperclips will the machine identify as defective, and what percentage of those will actually be defective?

Understand the Problem

The question is asking about a defect detection system in a factory. It wants to find out how many paperclips the machine will classify as defective and the percentage of those that are actually defective based on the given detection rates and the numbers provided.

Answer

The machine will identify **198** paperclips as defective, and **50%** of those will actually be defective.

Answer for screen readers

The machine will identify 198 paperclips as defective, and 50% of those will actually be defective.

Steps to Solve

-

Identify Total Paperclips There are a total of 10,000 paperclips in the production line.

-

Determine Number of Functional Paperclips 99% of the paperclips are functional, so: $$ \text{Functional paperclips} = 0.99 \times 10,000 = 9,900 $$

-

Determine Number of Defective Paperclips The remaining paperclips are defective. So: $$ \text{Defective paperclips} = 10,000 - 9,900 = 100 $$

-

Calculate Number of Defective Paperclips Identified The machine correctly detects 99% of defective paperclips. Thus: $$ \text{Identified as defective} = 0.99 \times 100 = 99 $$

-

Calculate Number of Functional Paperclips Misclassified The machine incorrectly identifies 1% of functional paperclips as defective. Therefore: $$ \text{Misclassified as defective} = 0.01 \times 9,900 = 99 $$

-

Total Number of Paperclips Identified as Defective Now add the correctly identified defective and the misclassified functional paperclips: $$ \text{Total identified as defective} = 99 + 99 = 198 $$

-

Calculate Percentage of Identified that are Actually Defective Now, to find the percentage of those identified as defective that are actually defective: $$ \text{Percentage actually defective} = \left( \frac{99}{198} \right) \times 100 \approx 50% $$

The machine will identify 198 paperclips as defective, and 50% of those will actually be defective.

More Information

In this problem, we calculated the effectiveness of a defect detection system by analyzing the rates of correct and incorrect classifications. This exercise is common in quality control processes.

Tips

- Forgetting to differentiate between functional and defective paperclips.

- Misapplying percentages, especially in the context of the total number of paperclips versus the functional ones.

- Confusing the results by not clearly identifying correctly identified and misclassified paperclips.

AI-generated content may contain errors. Please verify critical information