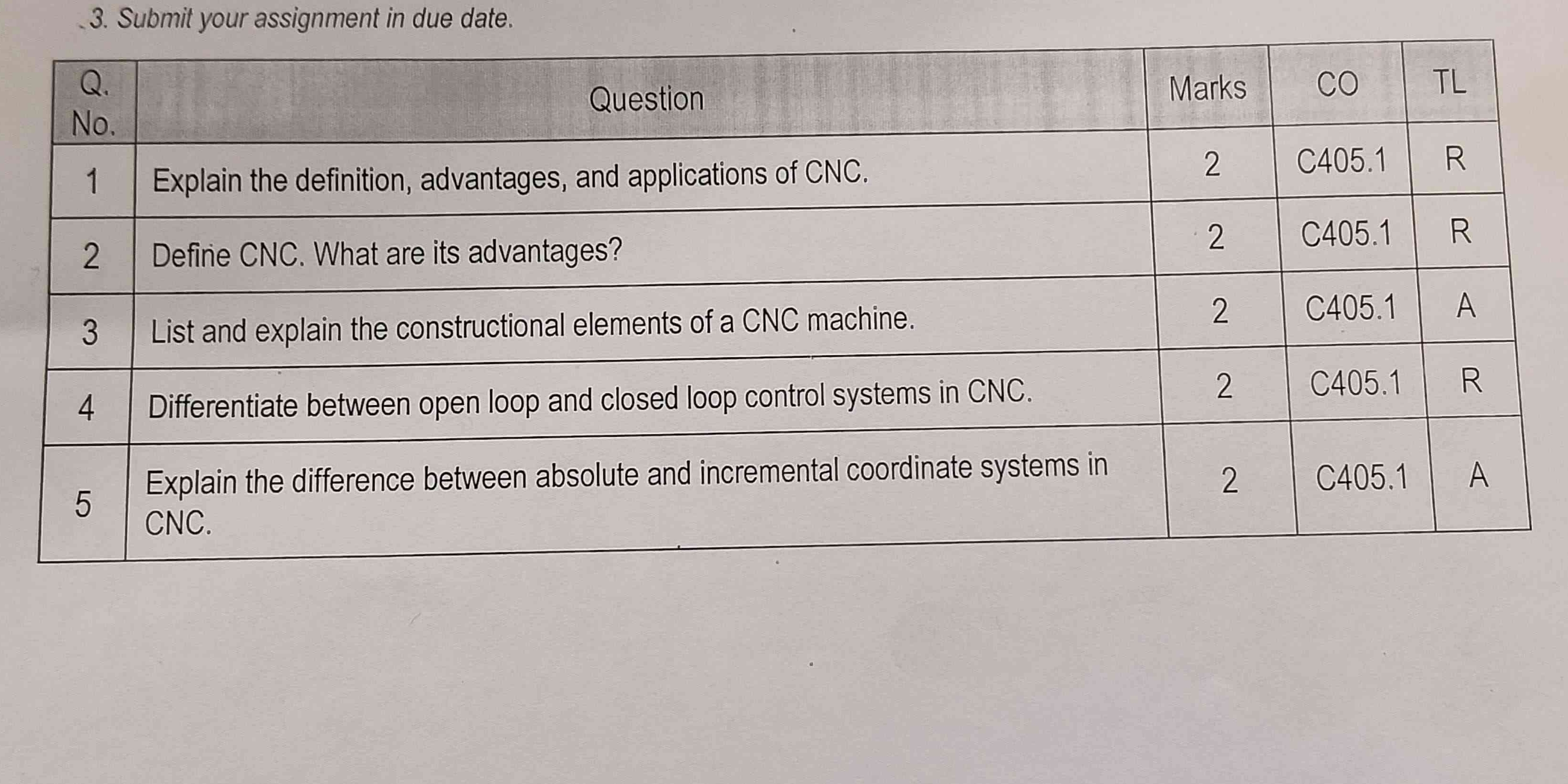

Explain the definition, advantages, and applications of CNC. Define CNC. What are its advantages? List and explain the constructional elements of a CNC machine. Differentiate betwe... Explain the definition, advantages, and applications of CNC. Define CNC. What are its advantages? List and explain the constructional elements of a CNC machine. Differentiate between open loop and closed loop control systems in CNC. Explain the difference between absolute and incremental coordinate systems in CNC.

Understand the Problem

The question is asking for explanations related to CNC (Computer Numerical Control) technology, including definitions, advantages, applications, construction elements, control systems, and coordinate systems. This involves discussing technical concepts in detail and providing clear comparisons.

Answer

CNC is Computer Numerical Control, offering precision, continuous operation, and applicability in diverse industries. Key elements include the bed, spindle, control panel, and drive system. Open loop lacks feedback; closed loop uses feedback. Absolute and incremental coordinates differ by their origin references.

Definitions:

- CNC (Computer Numerical Control): A technology where the functions and motions of a machine tool are controlled by a computer executing pre-programmed sequences of machine control commands.

Advantages:

- High accuracy and precision.

- Continuous operation with minimal downtime.

- Reduced human error and labor costs.

- Complex shapes and designs possible.

Applications include manufacturing, automotive, aerospace, and electronics industries.

Constructional Elements:

- Bed: Provides a base for the machine.

- Spindle: Rotates the cutting tool or the workpiece.

- Control Panel: Interface for operating the CNC machine.

- Drive System: Converts the command signals from the computer into motion.

Open Loop vs. Closed Loop:

- Open Loop: Control action is independent of the output; no feedback system.

- Closed Loop: Utilizes feedback to compare output actions to the desired input.

Absolute vs. Incremental Systems:

- Absolute Coordinates: Reference is taken from a fixed origin.

- Incremental Coordinates: Reference is taken from the last position of the tool.

Answer for screen readers

Definitions:

- CNC (Computer Numerical Control): A technology where the functions and motions of a machine tool are controlled by a computer executing pre-programmed sequences of machine control commands.

Advantages:

- High accuracy and precision.

- Continuous operation with minimal downtime.

- Reduced human error and labor costs.

- Complex shapes and designs possible.

Applications include manufacturing, automotive, aerospace, and electronics industries.

Constructional Elements:

- Bed: Provides a base for the machine.

- Spindle: Rotates the cutting tool or the workpiece.

- Control Panel: Interface for operating the CNC machine.

- Drive System: Converts the command signals from the computer into motion.

Open Loop vs. Closed Loop:

- Open Loop: Control action is independent of the output; no feedback system.

- Closed Loop: Utilizes feedback to compare output actions to the desired input.

Absolute vs. Incremental Systems:

- Absolute Coordinates: Reference is taken from a fixed origin.

- Incremental Coordinates: Reference is taken from the last position of the tool.

More Information

CNC technology has revolutionized manufacturing by allowing for greater precision and automation. The choice between absolute and incremental systems can affect the complexity and efficiency of programming.

Tips

A common mistake is confusing absolute and incremental coordinates, which can result in incorrect machining paths. Always verify coordinate systems and control feedback mechanisms during setup.

Sources

- A Comprehensive Guide To CNC Machines, Types & Advantages - davenportmachine.com

- What is a CNC Machine? CNC : Computerised Numerical Control - home.iitk.ac.in

- Numerical control - Wikipedia - en.wikipedia.org

AI-generated content may contain errors. Please verify critical information