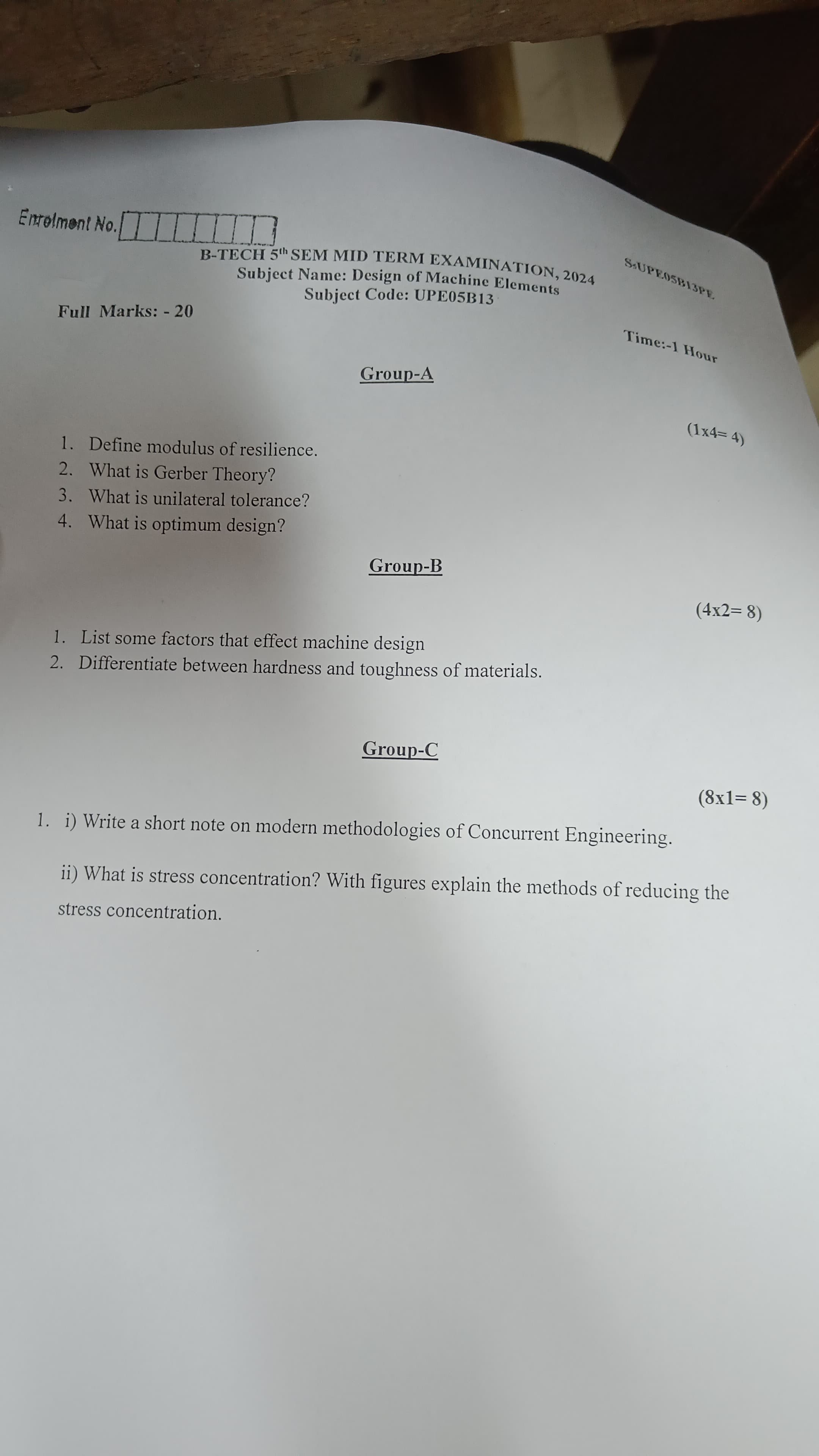

1. Define modulus of resilience. 2. What is Gerber Theory? 3. What is unilateral tolerance? 4. What is optimum design? 5. List some factors that affect machine design. 6. Different... 1. Define modulus of resilience. 2. What is Gerber Theory? 3. What is unilateral tolerance? 4. What is optimum design? 5. List some factors that affect machine design. 6. Differentiate between hardness and toughness of materials. 7. Write a short note on modern methodologies of Concurrent Engineering. 8. What is stress concentration? With figures explain the methods of reducing the stress concentration.

Understand the Problem

The question is asking for definitions and explanations related to engineering concepts, specifically those pertaining to mechanical design. This includes defining terms and explaining theories in the context of machine elements.

Answer

1. The modulus of resilience is the maximum energy per unit volume that can be elastically stored in a material without causing permanent distortion. 2. Gerber Theory is a parabolic relationship between mean stress and cyclic stress amplitude, predicting fatigue life. 3. Unilateral tolerance specifies dimensional variation in one direction. 4. Optimum design achieves the best performance according to criteria like cost and material usage. 5. Factors affecting machine design include material selection, load considerations, and manufacturing capabilities. 6. Hardness is resistance to deformation, while toughness is ability to absorb energy and deform without fracturing. 7. Modern Concurrent Engineering involves cross-functional teams for collaborative design to improve communication and reduce time to market. 8. Stress concentration is localized stress intensity, reduced by adding fillets, gradual transitions in cross-sections, and avoiding sudden geometric changes.

- The modulus of resilience is defined as the maximum energy per unit volume that can be elastically stored in a material and is absorbed during deformation without causing permanent distortion. 2. Gerber Theory, or the Gerber line, is used in fatigue analysis and is a parabolic relationship between mean stress and the amplitude of cyclic stress; it predicts the life of a component under cyclic loading. 3. Unilateral tolerance specifies a dimensional variation in one direction only (either positive or negative) from the nominal dimension. 4. Optimum design in engineering refers to designing systems or components in a way that achieves the best performance according to specified criteria such as cost, efficiency, and material usage. 5. Some factors that affect machine design include material selection, load and force considerations, environmental conditions, reliability, manufacturing process capabilities, cost constraints, and safety requirements. 6. Hardness is the resistance to deformation or scratching, while toughness is the ability of a material to absorb energy and plastically deform without fracturing. 7. Modern methodologies of Concurrent Engineering involve bringing together cross-functional teams to design and develop products collaboratively from the outset of the project, improving communication, and reducing time to market. 8. Stress concentration is the occurrence of stress intensities at certain points in a component; it can be reduced using techniques such as adding fillets to sharp corners, using gradual transitions in cross-sections, and avoiding sudden changes in geometry.

Answer for screen readers

- The modulus of resilience is defined as the maximum energy per unit volume that can be elastically stored in a material and is absorbed during deformation without causing permanent distortion. 2. Gerber Theory, or the Gerber line, is used in fatigue analysis and is a parabolic relationship between mean stress and the amplitude of cyclic stress; it predicts the life of a component under cyclic loading. 3. Unilateral tolerance specifies a dimensional variation in one direction only (either positive or negative) from the nominal dimension. 4. Optimum design in engineering refers to designing systems or components in a way that achieves the best performance according to specified criteria such as cost, efficiency, and material usage. 5. Some factors that affect machine design include material selection, load and force considerations, environmental conditions, reliability, manufacturing process capabilities, cost constraints, and safety requirements. 6. Hardness is the resistance to deformation or scratching, while toughness is the ability of a material to absorb energy and plastically deform without fracturing. 7. Modern methodologies of Concurrent Engineering involve bringing together cross-functional teams to design and develop products collaboratively from the outset of the project, improving communication, and reducing time to market. 8. Stress concentration is the occurrence of stress intensities at certain points in a component; it can be reduced using techniques such as adding fillets to sharp corners, using gradual transitions in cross-sections, and avoiding sudden changes in geometry.

More Information

Stress concentration occurs in areas such as sharp corners, holes, notches, or other abrupt changes in the geometry of the component. Using gradual transitions, rounded corners, and stress relievers like holes can help in mitigating the effects.

Tips

A common mistake in understanding material properties is confusing hardness and toughness. Remember, hardness is about resistance to surface deformation, while toughness is about energy absorption and resistance to fracturing.

Sources

- Modulus of Resilience: Formula, Units, Calculation, & Importance - testbook.com

- Principles of Tolerancing | Engineering Design - McGill University - mcgill.ca

- Resilience (materials science) - Wikipedia - en.wikipedia.org

AI-generated content may contain errors. Please verify critical information