Podcast

Questions and Answers

What are the three components that Overall Equipment Effectiveness (OEE) divides a production step's performance into?

What are the three components that Overall Equipment Effectiveness (OEE) divides a production step's performance into?

- Availability, performance, and quality (correct)

- Maintenance, production, and control

- Efficiency, capacity, and speed

- Flexibility, sustainability, and demand

In manufacturing quality within OEE, what does the proportion of the product's output reaching quality standards represent?

In manufacturing quality within OEE, what does the proportion of the product's output reaching quality standards represent?

- The planned speed

- The total output

- The theoretical operating times

- A measure of quality in relation to total output (correct)

What should organizations consider when defining benchmarks for utilization levels?

What should organizations consider when defining benchmarks for utilization levels?

- Universal industry standards

- National regulatory requirements

- Historical data from competitors

- Specific organizational goals and operational context (correct)

Why is it important to strike a balance between efficiency and factors like equipment maintenance in production processes?

Why is it important to strike a balance between efficiency and factors like equipment maintenance in production processes?

What aspect of transportation data within the value stream should be carefully examined to optimize delivery processes?

What aspect of transportation data within the value stream should be carefully examined to optimize delivery processes?

How does OEE calculate manufacturing performance?

How does OEE calculate manufacturing performance?

What does the availability component of OEE represent?

What does the availability component of OEE represent?

Why is it necessary to focus on delivery frequencies in transportation data within the value stream?

Why is it necessary to focus on delivery frequencies in transportation data within the value stream?

Which factor should organizations prioritize when balancing efficiency in production processes?

Which factor should organizations prioritize when balancing efficiency in production processes?

What does the manufacturing quality component of OEE assess?

What does the manufacturing quality component of OEE assess?

Flashcards are hidden until you start studying

Study Notes

Value Stream Mapping

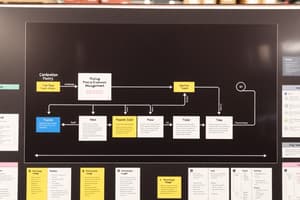

- A Value Stream Map (VSM) visualizes how information moves between different parts of the company, highlighting data processing processes and identifying delays.

Improving Value Stream Performance

- Leveled flow design helps achieve steady and balanced material flows, improving value stream performance.

- Removing imbalances in the whole process is necessary for sustainable improvement.

Stable and Efficient Processes

- Stable and reliable manufacturing processes are essential for successful LEAN Planning.

- Unstable production processes can impede the design of an optimal Rhythm Wheel.

- Lean tools like SMED, Root Cause Analysis, Poka Yoke, TPM, and 5S can improve stability and efficiency in manufacturing operations.

Information Flows

- Information processing can be time-consuming, involving data gathering, sharing, and processing.

- A VSM helps visualize information flows, showing how data moves between different parts of the company and with customers and suppliers.

- A VSM highlights data processing processes, frequency of data generation, and delays in data processing.

Optimal Utilization Levels

- Optimal utilization levels vary across industries and individual processes, with no universal "ideal" rate.

- Benchmarks should be based on specific organizational goals and operational context.

- A balance must be struck between efficiency and factors like equipment maintenance, quality control, and flexibility.

Overall Equipment Effectiveness (OEE)

- OEE measures a production step's performance in three components: availability, performance, and quality.

- Availability represents the percentage of scheduled time available for production.

- Performance measures the actual speed of production compared to planned speed.

- Quality represents the proportion of output meeting quality standards.

Transportation Data

- Transportation aspects within the value stream should be examined, focusing on delivery frequencies, transport lot sizes, and transportation lead times.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.