Podcast

Questions and Answers

What is a Value Stream?

What is a Value Stream?

- A specific product or service offered by a company.

- A single process within an organization, such as manufacturing or design.

- A detailed report outlining the financial performance of a company.

- A flow of information and/or materials and/or ideas throughout an entire enterprise that starts and ends with the customer. (correct)

Which of the following is NOT a benefit of Value Stream Mapping?

Which of the following is NOT a benefit of Value Stream Mapping?

- Identifying Value Add and Non Value Add steps.

- Identifying the critical processes (constraints).

- Improving communication and collaboration across departments.

- Increasing the number of steps in the process for better efficiency. (correct)

In a typical Food Manufacture Value Stream Map, what would be considered the 'items' that flow through the process?

In a typical Food Manufacture Value Stream Map, what would be considered the 'items' that flow through the process?

- The machines used to process the food.

- Information about customer preferences.

- The raw ingredients used in the food production. (correct)

- The finished food products ready for sale.

What is the first step in mapping and improving a process using Value Stream Mapping?

What is the first step in mapping and improving a process using Value Stream Mapping?

Which of the following is a metric that could be used to measure process performance in Value Stream Mapping?

Which of the following is a metric that could be used to measure process performance in Value Stream Mapping?

What is the primary purpose of the 'Future State' map in Value Stream Mapping?

What is the primary purpose of the 'Future State' map in Value Stream Mapping?

Why does Value Stream Mapping emphasize starting at the end of the process and working backwards?

Why does Value Stream Mapping emphasize starting at the end of the process and working backwards?

What is a major advantage of using Post-it Notes in Value Stream Mapping?

What is a major advantage of using Post-it Notes in Value Stream Mapping?

Flashcards

Value Stream

Value Stream

The flow of information and materials throughout an enterprise, focusing on customer demand.

Value Stream Mapping (VSM)

Value Stream Mapping (VSM)

A visual tool to analyze and improve the flow of materials and information in a process.

Value Add Steps

Value Add Steps

Processes that contribute directly to customer value in the supply chain.

Non Value Add Steps

Non Value Add Steps

Signup and view all the flashcards

Critical Processes (Constraints)

Critical Processes (Constraints)

Signup and view all the flashcards

Performance Measures

Performance Measures

Signup and view all the flashcards

Mapping Process Steps

Mapping Process Steps

Signup and view all the flashcards

Future State Mapping

Future State Mapping

Signup and view all the flashcards

Study Notes

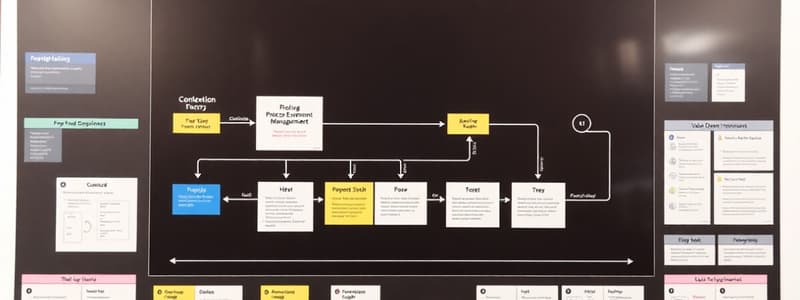

Value Stream Mapping (VSM)

- A value stream is the flow of information, materials, or ideas throughout an entire enterprise, starting and ending with the customer.

- It depicts demand and the enterprise's fulfillment of that demand.

- It identifies value-added and non-value-added steps in the entire supply chain.

- It pinpoints critical processes (constraints).

- It measures performance at each step.

What Flows Through a Value Stream?

- Items flow through value streams.

- In manufacturing, materials are items.

- In design and development, designs are items.

- In service, external customer needs are items.

- In administration, internal customer needs are items.

- Customers are both internal and external.

Measuring Value Stream Processes

- Each process/activity should be measured to understand its impact and improvement potential.

- Examples of measurements include:

- Step duration

- Setup time

- Accuracy

- Yield

- Resources required

- Installation time

- Energy consumption

Examples of Measurable Metrics

- Time to setup

- Time to pack one item

- Yield percentage

- Waste (kilograms)

- Packing product

Mapping and Improving a Process

- Decide which process to map.

- Form a multi-disciplinary team.

- Start at the end of the process and work backward.

- Walk the process with the process owner.

- Collect process information and metrics.

- Use post-it notes to record each step and its metrics.

- Identify problem areas and areas for improvement.

- Use Lean tools to design an improved future state.

- Improve the process, verify it works, and redraw the map.

Current vs. Future State Maps

- VSMs illustrate current and future states of a process.

- Current-state maps depict the existing process.

- Future-state maps highlight improvements.

Typical VSM Examples

- Examples of value stream maps are provided for food manufacturing and pharmaceutical manufacturing.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.