Podcast

Questions and Answers

What is the product discussed in the document?

What is the product discussed in the document?

VACUTAP® RMV-II on-load tap-changer

Who is the manufacturer of the product?

Who is the manufacturer of the product?

Reinhausen Manufacturing Inc.

What should be kept ready at hand and accessible for future use?

What should be kept ready at hand and accessible for future use?

This technical file and all supporting documents

The technical file is intended for untrained personnel.

The technical file is intended for untrained personnel.

Signup and view all the answers

What types of supporting documents are needed for the technical file?

What types of supporting documents are needed for the technical file?

Signup and view all the answers

Where can further information and copies of the technical file be obtained?

Where can further information and copies of the technical file be obtained?

Signup and view all the answers

Only trained technicians should perform work on the transformer.

Only trained technicians should perform work on the transformer.

Signup and view all the answers

What must be ensured to prevent explosions or injuries during transformer commissioning?

What must be ensured to prevent explosions or injuries during transformer commissioning?

Signup and view all the answers

The oil compartment of the on-load tap-changer must be correctly filled with _____ as per the instructions.

The oil compartment of the on-load tap-changer must be correctly filled with _____ as per the instructions.

Signup and view all the answers

Which of the following actions should be avoided during transformer testing?

Which of the following actions should be avoided during transformer testing?

Signup and view all the answers

What should be done if the monitoring system trips during operation?

What should be done if the monitoring system trips during operation?

Signup and view all the answers

What happens in the event of an error according to the monitoring system?

What happens in the event of an error according to the monitoring system?

Signup and view all the answers

The green TEST push-button is used to check the internal circuitry of the monitoring system.

The green TEST push-button is used to check the internal circuitry of the monitoring system.

Signup and view all the answers

What does the yellow LED indicate on the monitoring circuit board?

What does the yellow LED indicate on the monitoring circuit board?

Signup and view all the answers

What kind of packaging do the products sometimes come in?

What kind of packaging do the products sometimes come in?

Signup and view all the answers

The dehydrating breather removes moisture from the air breathed into the on-load tap-changer. It comprises a ______.

The dehydrating breather removes moisture from the air breathed into the on-load tap-changer. It comprises a ______.

Signup and view all the answers

What is the recommended maximum height for stacking crates?

What is the recommended maximum height for stacking crates?

Signup and view all the answers

The green Power LED indicates when a vacuum interrupter malfunction has been recorded.

The green Power LED indicates when a vacuum interrupter malfunction has been recorded.

Signup and view all the answers

What should you do if external transport damage is found upon receipt of the shipment?

What should you do if external transport damage is found upon receipt of the shipment?

Signup and view all the answers

What must you check before starting to fit the motor-drive unit?

What must you check before starting to fit the motor-drive unit?

Signup and view all the answers

Match the following components of the monitoring system with their functions:

Match the following components of the monitoring system with their functions:

Signup and view all the answers

What type of protective equipment is recommended to protect the eyes?

What type of protective equipment is recommended to protect the eyes?

Signup and view all the answers

What does the RMV-II on-load tap-changer primarily control?

What does the RMV-II on-load tap-changer primarily control?

Signup and view all the answers

What component is used to interrupt the circuit in the RMV-II on-load tap-changer?

What component is used to interrupt the circuit in the RMV-II on-load tap-changer?

Signup and view all the answers

The tap changer operation can only occur in a specific order.

The tap changer operation can only occur in a specific order.

Signup and view all the answers

The on-load tap-changer's name plate is located on the door of the ______.

The on-load tap-changer's name plate is located on the door of the ______.

Signup and view all the answers

Match the protective devices included with the motor-drive unit:

Match the protective devices included with the motor-drive unit:

Signup and view all the answers

What happens if the voltage is interrupted during an on-load tap-change operation?

What happens if the voltage is interrupted during an on-load tap-change operation?

Signup and view all the answers

What is the function of the motor-drive unit?

What is the function of the motor-drive unit?

Signup and view all the answers

The monitoring system provides protection during manual actuation of the RAISE/LOWER rotary switch.

The monitoring system provides protection during manual actuation of the RAISE/LOWER rotary switch.

Signup and view all the answers

What does the signal word 'DANGER' indicate?

What does the signal word 'DANGER' indicate?

Signup and view all the answers

Embedded warnings apply to larger units of information than warnings relating to sections.

Embedded warnings apply to larger units of information than warnings relating to sections.

Signup and view all the answers

Which of the following is a required personal protective equipment?

Which of the following is a required personal protective equipment?

Signup and view all the answers

What should be observed to prevent personal injuries during tap change operations?

What should be observed to prevent personal injuries during tap change operations?

Signup and view all the answers

The product is designed solely for use in __________ energy systems and facilities.

The product is designed solely for use in __________ energy systems and facilities.

Signup and view all the answers

What does the signal word 'CAUTION' indicate?

What does the signal word 'CAUTION' indicate?

Signup and view all the answers

Which of the following is NOT a type of signal word mentioned?

Which of the following is NOT a type of signal word mentioned?

Signup and view all the answers

What are the necessary requirements for personnel handling electrical systems?

What are the necessary requirements for personnel handling electrical systems?

Signup and view all the answers

Match the following terms with their meanings:

Match the following terms with their meanings:

Signup and view all the answers

Unauthorized modifications to the product can lead to personal injury.

Unauthorized modifications to the product can lead to personal injury.

Signup and view all the answers

What are the two assembly variants for the motor-drive unit?

What are the two assembly variants for the motor-drive unit?

Signup and view all the answers

Which process should be carried out before filling the on-load tap-changer with oil?

Which process should be carried out before filling the on-load tap-changer with oil?

Signup and view all the answers

The adjustment markings on the by-pass switch should be aligned to __________.

The adjustment markings on the by-pass switch should be aligned to __________.

Signup and view all the answers

The maximum tightening torque for the access door to the on-load tap-changer is 15 ft·lb.

The maximum tightening torque for the access door to the on-load tap-changer is 15 ft·lb.

Signup and view all the answers

What is the maximum differential pressure allowed for the terminal board in the on-load tap-changer?

What is the maximum differential pressure allowed for the terminal board in the on-load tap-changer?

Signup and view all the answers

What is the maximum number of tap-change operations allowed without complete oil filling to avoid damage?

What is the maximum number of tap-change operations allowed without complete oil filling to avoid damage?

Signup and view all the answers

To prevent moisture contamination, always break the vacuum with __________.

To prevent moisture contamination, always break the vacuum with __________.

Signup and view all the answers

What is necessary to check the neutral position of the on-load tap-changer?

What is necessary to check the neutral position of the on-load tap-changer?

Signup and view all the answers

What should you do after withdrawing the hand crank?

What should you do after withdrawing the hand crank?

Signup and view all the answers

Only trained technicians should perform work on the transformer.

Only trained technicians should perform work on the transformer.

Signup and view all the answers

What should be ensured regarding the oil compartment of the on-load tap-changer?

What should be ensured regarding the oil compartment of the on-load tap-changer?

Signup and view all the answers

What should be done if the monitoring system trips during operation?

What should be done if the monitoring system trips during operation?

Signup and view all the answers

Which of the following is NOT recommended when working near the transformer?

Which of the following is NOT recommended when working near the transformer?

Signup and view all the answers

The danger of death during commissioning can occur due to _____ operation.

The danger of death during commissioning can occur due to _____ operation.

Signup and view all the answers

What indicates a fault in the signal transmission in the monitoring system?

What indicates a fault in the signal transmission in the monitoring system?

Signup and view all the answers

What is the purpose of the red RESET push-button in the monitoring system?

What is the purpose of the red RESET push-button in the monitoring system?

Signup and view all the answers

The packaging for the products can be used in unheated buildings.

The packaging for the products can be used in unheated buildings.

Signup and view all the answers

What should be checked for completeness before accepting a shipment?

What should be checked for completeness before accepting a shipment?

Signup and view all the answers

How many red LEDs indicate a vacuum interrupter malfunction?

How many red LEDs indicate a vacuum interrupter malfunction?

Signup and view all the answers

What should be done if external transport damage is found upon receipt?

What should be done if external transport damage is found upon receipt?

Signup and view all the answers

The on-load tap-changer is shipped filled with _____ under positive pressure.

The on-load tap-changer is shipped filled with _____ under positive pressure.

Signup and view all the answers

The monitoring system performs a check of the internal circuitry only during installation.

The monitoring system performs a check of the internal circuitry only during installation.

Signup and view all the answers

Match the following LED indicators with their corresponding issues:

Match the following LED indicators with their corresponding issues:

Signup and view all the answers

What should be done before fitting the on-load tap-changer to the transformer?

What should be done before fitting the on-load tap-changer to the transformer?

Signup and view all the answers

Warnings relating to sections refer to entire chapters or sections, sub-sections or several paragraphs within this technical file. Warnings relating to sections use the following format: WARNING ________!

Warnings relating to sections refer to entire chapters or sections, sub-sections or several paragraphs within this technical file. Warnings relating to sections use the following format: WARNING ________!

Signup and view all the answers

Embedded warnings use a format that includes DANGER! ________ for avoiding a dangerous situation.

Embedded warnings use a format that includes DANGER! ________ for avoiding a dangerous situation.

Signup and view all the answers

Which signal word indicates a hazardous situation which, if not avoided, will result in death or serious injury?

Which signal word indicates a hazardous situation which, if not avoided, will result in death or serious injury?

Signup and view all the answers

What does the signal word 'CAUTION' indicate?

What does the signal word 'CAUTION' indicate?

Signup and view all the answers

The product can be used for any purpose in electrical energy systems and facilities.

The product can be used for any purpose in electrical energy systems and facilities.

Signup and view all the answers

What personal protective equipment should be worn to prevent becoming trapped in rotating parts?

What personal protective equipment should be worn to prevent becoming trapped in rotating parts?

Signup and view all the answers

The limit step capacity is the largest step capacity that can be switched safely.

The limit step capacity is the largest step capacity that can be switched safely.

Signup and view all the answers

Which of the following is an appropriate measure to prevent tap change operations?

Which of the following is an appropriate measure to prevent tap change operations?

Signup and view all the answers

What should be done if safety markings on the product are damaged or missing?

What should be done if safety markings on the product are damaged or missing?

Signup and view all the answers

Match the personnel qualification with their respective descriptions:

Match the personnel qualification with their respective descriptions:

Signup and view all the answers

Which personal protective equipment is used to protect the eyes from flying parts?

Which personal protective equipment is used to protect the eyes from flying parts?

Signup and view all the answers

What component is equipped with an oil drain valve?

What component is equipped with an oil drain valve?

Signup and view all the answers

What type of transformers is the RMV-II on-load tap-changer used with?

What type of transformers is the RMV-II on-load tap-changer used with?

Signup and view all the answers

The vacuum interrupter operates outside of the oil.

The vacuum interrupter operates outside of the oil.

Signup and view all the answers

What operation does the motor-drive unit perform?

What operation does the motor-drive unit perform?

Signup and view all the answers

A ______ device provides pressure relief in the oil compartment.

A ______ device provides pressure relief in the oil compartment.

Signup and view all the answers

Match the components of the motor-drive unit with their functions:

Match the components of the motor-drive unit with their functions:

Signup and view all the answers

What does the VIM module stand for?

What does the VIM module stand for?

Signup and view all the answers

Who manufactures the VACUTAP® RMV-II on-load tap-changer?

Who manufactures the VACUTAP® RMV-II on-load tap-changer?

Signup and view all the answers

The technical file for the VACUTAP® RMV-II is intended for general public use.

The technical file for the VACUTAP® RMV-II is intended for general public use.

Signup and view all the answers

What is the standard position designation range for the VACUTAP® RMV-II?

What is the standard position designation range for the VACUTAP® RMV-II?

Signup and view all the answers

This technical file is complete without supporting documents.

This technical file is complete without supporting documents.

Signup and view all the answers

The manufacturer of the VACUTAP® RMV-II can be found at 2549 North 9th Avenue, _____, Tennessee, USA.

The manufacturer of the VACUTAP® RMV-II can be found at 2549 North 9th Avenue, _____, Tennessee, USA.

Signup and view all the answers

Where can further information on the product be obtained?

Where can further information on the product be obtained?

Signup and view all the answers

What should you do with the technical file and supporting documents?

What should you do with the technical file and supporting documents?

Signup and view all the answers

What two positions should both change-over selector contacts be in to check the neutral position?

What two positions should both change-over selector contacts be in to check the neutral position?

Signup and view all the answers

What needs to be aligned on the by-pass switch for checking the neutral position?

What needs to be aligned on the by-pass switch for checking the neutral position?

Signup and view all the answers

What should the tap position indicator indicate at neutral?

What should the tap position indicator indicate at neutral?

Signup and view all the answers

What are the two assembly variants for the motor-drive unit?

What are the two assembly variants for the motor-drive unit?

Signup and view all the answers

What should be done if any aspect of the tests after assembly is unclear?

What should be done if any aspect of the tests after assembly is unclear?

Signup and view all the answers

The maximum permitted tightening torque for the access door to the on-load tap-changer is _____ ft·lb.

The maximum permitted tightening torque for the access door to the on-load tap-changer is _____ ft·lb.

Signup and view all the answers

What is the maximum temperature during the drying of the on-load tap-changer?

What is the maximum temperature during the drying of the on-load tap-changer?

Signup and view all the answers

What must be filled to the mark in the oil compartment before applying operating voltage?

What must be filled to the mark in the oil compartment before applying operating voltage?

Signup and view all the answers

Which items must be removed before drying the on-load tap-changer?

Which items must be removed before drying the on-load tap-changer?

Signup and view all the answers

The operating instructions for the motor-drive unit provide detailed descriptions of checking its functionality.

The operating instructions for the motor-drive unit provide detailed descriptions of checking its functionality.

Signup and view all the answers

What must be done to prevent damage when measuring DC resistance on transformers?

What must be done to prevent damage when measuring DC resistance on transformers?

Signup and view all the answers

What is the primary purpose of the VACUTAP® RMV-II operating instructions?

What is the primary purpose of the VACUTAP® RMV-II operating instructions?

Signup and view all the answers

Who manufactures the VACUTAP® RMV-II?

Who manufactures the VACUTAP® RMV-II?

Signup and view all the answers

The technical file applies to the VACUTAP® RMV-II without any specific designations.

The technical file applies to the VACUTAP® RMV-II without any specific designations.

Signup and view all the answers

What should you keep accessible for future use?

What should you keep accessible for future use?

Signup and view all the answers

What is the email contact for further information about the product?

What is the email contact for further information about the product?

Signup and view all the answers

This technical file is incomplete without the supporting documents: Technical data and drawings which are provided upon ______.

This technical file is incomplete without the supporting documents: Technical data and drawings which are provided upon ______.

Signup and view all the answers

How should warnings in the technical file be displayed?

How should warnings in the technical file be displayed?

Signup and view all the answers

Only trained technicians should perform work on the transformer.

Only trained technicians should perform work on the transformer.

Signup and view all the answers

Which of the following is a danger when working with the on-load tap-changer?

Which of the following is a danger when working with the on-load tap-changer?

Signup and view all the answers

What should be observed during transformer tests?

What should be observed during transformer tests?

Signup and view all the answers

Before starting up the transformer, the functions described in the _____ chapter must be satisfied.

Before starting up the transformer, the functions described in the _____ chapter must be satisfied.

Signup and view all the answers

It is safe to actuate the on-load tap-changer with the hand crank while the transformer is energized.

It is safe to actuate the on-load tap-changer with the hand crank while the transformer is energized.

Signup and view all the answers

What should be done if the monitoring system trips during operation?

What should be done if the monitoring system trips during operation?

Signup and view all the answers

What does the signal word 'DANGER' indicate?

What does the signal word 'DANGER' indicate?

Signup and view all the answers

What are embedded warnings used for?

What are embedded warnings used for?

Signup and view all the answers

The on-load tap-changer can be used in an area with a risk of explosion.

The on-load tap-changer can be used in an area with a risk of explosion.

Signup and view all the answers

Which of the following is NOT a signal word used in warning notices?

Which of the following is NOT a signal word used in warning notices?

Signup and view all the answers

What is the purpose of personal protective equipment?

What is the purpose of personal protective equipment?

Signup and view all the answers

The __________ helps to ensure that the product is used safely and properly.

The __________ helps to ensure that the product is used safely and properly.

Signup and view all the answers

Only qualified personnel should perform necessary work on the product.

Only qualified personnel should perform necessary work on the product.

Signup and view all the answers

Match the following signal words with their meanings:

Match the following signal words with their meanings:

Signup and view all the answers

What should be done if personal protective equipment is damaged?

What should be done if personal protective equipment is damaged?

Signup and view all the answers

What are the two assembly variants for the motor-drive unit?

What are the two assembly variants for the motor-drive unit?

Signup and view all the answers

What should be checked first to determine the motor-drive unit's neutral position?

What should be checked first to determine the motor-drive unit's neutral position?

Signup and view all the answers

What is the maximum tightening torque for the nuts on the access door to the on-load tap-changer?

What is the maximum tightening torque for the nuts on the access door to the on-load tap-changer?

Signup and view all the answers

To avoid damaging the motor-drive unit, perform no more than ___ tap-change operations in succession.

To avoid damaging the motor-drive unit, perform no more than ___ tap-change operations in succession.

Signup and view all the answers

The on-load tap-changer must be filled with oil to the corresponding mark under normal atmospheric pressure.

The on-load tap-changer must be filled with oil to the corresponding mark under normal atmospheric pressure.

Signup and view all the answers

What should be removed from the on-load tap-changer before drying?

What should be removed from the on-load tap-changer before drying?

Signup and view all the answers

What is the temperature increase limit when heating up the on-load tap-changer during drying?

What is the temperature increase limit when heating up the on-load tap-changer during drying?

Signup and view all the answers

How long should the vacuum dry on-load tap-changer at a temperature between 105 °C and maximum 110 °C?

How long should the vacuum dry on-load tap-changer at a temperature between 105 °C and maximum 110 °C?

Signup and view all the answers

What must be done to the oil compartment of the on-load tap-changer before applying operating voltage?

What must be done to the oil compartment of the on-load tap-changer before applying operating voltage?

Signup and view all the answers

What is the purpose of safety glasses?

What is the purpose of safety glasses?

Signup and view all the answers

What does the RMV-II on-load tap-changer do?

What does the RMV-II on-load tap-changer do?

Signup and view all the answers

The on-load tap-changer operates without causing contamination of the oil.

The on-load tap-changer operates without causing contamination of the oil.

Signup and view all the answers

What is the function of the motor-drive unit in the tap-changer?

What is the function of the motor-drive unit in the tap-changer?

Signup and view all the answers

The ______ protects from falling and flying parts.

The ______ protects from falling and flying parts.

Signup and view all the answers

What type of interrupter is used in the RMV-II on-load tap-changer?

What type of interrupter is used in the RMV-II on-load tap-changer?

Signup and view all the answers

Which protective device responds to a defined overpressure in the oil compartment?

Which protective device responds to a defined overpressure in the oil compartment?

Signup and view all the answers

The tap changer can only proceed to the next position if all control devices are at their resting positions.

The tap changer can only proceed to the next position if all control devices are at their resting positions.

Signup and view all the answers

Match the following components to their descriptions:

Match the following components to their descriptions:

Signup and view all the answers

What actions are triggered by the monitoring system in the event of an error? (Select all that apply)

What actions are triggered by the monitoring system in the event of an error? (Select all that apply)

Signup and view all the answers

The monitoring system uses a red LED to indicate faults in signal transmission.

The monitoring system uses a red LED to indicate faults in signal transmission.

Signup and view all the answers

What does the green TEST push-button do in the monitoring system?

What does the green TEST push-button do in the monitoring system?

Signup and view all the answers

What is the purpose of the dehydrating breather?

What is the purpose of the dehydrating breather?

Signup and view all the answers

The packaged goods are packed in a sturdy ______.

The packaged goods are packed in a sturdy ______.

Signup and view all the answers

Stacking crates above a height of 1.5 m is safe as long as they are equally sized.

Stacking crates above a height of 1.5 m is safe as long as they are equally sized.

Signup and view all the answers

What should be done if external transport damage is found on receipt of a shipment? (Select all that apply)

What should be done if external transport damage is found on receipt of a shipment? (Select all that apply)

Signup and view all the answers

How should the on-load tap-changer be stored if kept outdoors?

How should the on-load tap-changer be stored if kept outdoors?

Signup and view all the answers

Only trained and authorized persons should select the sling gear and secure the load when transporting the crate.

Only trained and authorized persons should select the sling gear and secure the load when transporting the crate.

Signup and view all the answers

What happens to the on-load tap-changer and motor-drive unit during shipment?

What happens to the on-load tap-changer and motor-drive unit during shipment?

Signup and view all the answers

Use suitable _____ to protect components near welding from radiant heat.

Use suitable _____ to protect components near welding from radiant heat.

Signup and view all the answers

What does this technical file cover?

What does this technical file cover?

Signup and view all the answers

Who is the manufacturer of the VACUTAP® RMV-II?

Who is the manufacturer of the VACUTAP® RMV-II?

Signup and view all the answers

What must be kept accessible for future use regarding the technical file?

What must be kept accessible for future use regarding the technical file?

Signup and view all the answers

What is the range of standard position designations for the VACUTAP® RMV-II?

What is the range of standard position designations for the VACUTAP® RMV-II?

Signup and view all the answers

What should you refer to for specific details related to the VACUTAP® RMV-II?

What should you refer to for specific details related to the VACUTAP® RMV-II?

Signup and view all the answers

This technical file is intended solely for specially trained and ________ personnel.

This technical file is intended solely for specially trained and ________ personnel.

Signup and view all the answers

The technical file is complete without any supporting documents.

The technical file is complete without any supporting documents.

Signup and view all the answers

What happens in the event of an error in the monitoring system?

What happens in the event of an error in the monitoring system?

Signup and view all the answers

What does a yellow LED indicate on the monitoring circuit board?

What does a yellow LED indicate on the monitoring circuit board?

Signup and view all the answers

What should be done with the motor protective switch before fitting the motor-drive unit?

What should be done with the motor protective switch before fitting the motor-drive unit?

Signup and view all the answers

The packaged goods are protected from humidity using a _____

The packaged goods are protected from humidity using a _____

Signup and view all the answers

The dehydrating breather is used to add moisture to the air in the on-load tap-changer.

The dehydrating breather is used to add moisture to the air in the on-load tap-changer.

Signup and view all the answers

What is the maximum pressure allowed for storing the on-load tap-changer tank?

What is the maximum pressure allowed for storing the on-load tap-changer tank?

Signup and view all the answers

What is the recommended stack height for equally sized crates?

What is the recommended stack height for equally sized crates?

Signup and view all the answers

Hidden damages are always noticeable immediately upon unpacking.

Hidden damages are always noticeable immediately upon unpacking.

Signup and view all the answers

The monitoring system check occurs after every __ tap-change operations for network applications.

The monitoring system check occurs after every __ tap-change operations for network applications.

Signup and view all the answers

Which signal word indicates a hazardous situation that could result in death or serious injury?

Which signal word indicates a hazardous situation that could result in death or serious injury?

Signup and view all the answers

The on-load tap-changer is designed for use in non-electrical energy systems.

The on-load tap-changer is designed for use in non-electrical energy systems.

Signup and view all the answers

What must be worn to minimize risks to health during work?

What must be worn to minimize risks to health during work?

Signup and view all the answers

An ______ is required to identify potential dangers independently.

An ______ is required to identify potential dangers independently.

Signup and view all the answers

Match the following safety measures with their descriptions:

Match the following safety measures with their descriptions:

Signup and view all the answers

What should be done to ensure safe operation of the product?

What should be done to ensure safe operation of the product?

Signup and view all the answers

What is the limit for the rated step voltage Uir that can be exceeded for a short period?

What is the limit for the rated step voltage Uir that can be exceeded for a short period?

Signup and view all the answers

Unauthorized changes to the product may lead to operational faults.

Unauthorized changes to the product may lead to operational faults.

Signup and view all the answers

What is used to protect the eyes from flying parts and splashing liquids?

What is used to protect the eyes from flying parts and splashing liquids?

Signup and view all the answers

Which components are included in the oil compartment?

Which components are included in the oil compartment?

Signup and view all the answers

What is the function of the RMV-II on-load tap-changer?

What is the function of the RMV-II on-load tap-changer?

Signup and view all the answers

The tap changer operation is divided into two major functions.

The tap changer operation is divided into two major functions.

Signup and view all the answers

Where is the on-load tap-changer's name plate located?

Where is the on-load tap-changer's name plate located?

Signup and view all the answers

The vacuum interrupter operates on the principle of ______.

The vacuum interrupter operates on the principle of ______.

Signup and view all the answers

What device responds to defined overpressure in the oil compartment?

What device responds to defined overpressure in the oil compartment?

Signup and view all the answers

What happens during a voltage interruption during an on-load tap-change operation?

What happens during a voltage interruption during an on-load tap-change operation?

Signup and view all the answers

What is the name of the monitoring system for vacuum interrupters?

What is the name of the monitoring system for vacuum interrupters?

Signup and view all the answers

Which personal protective measures should be taken during transformer commissioning?

Which personal protective measures should be taken during transformer commissioning?

Signup and view all the answers

You can start up the transformer without checking the functions described in the Checks after assembly.

You can start up the transformer without checking the functions described in the Checks after assembly.

Signup and view all the answers

What must be done if the monitoring system trips during operation?

What must be done if the monitoring system trips during operation?

Signup and view all the answers

What should be used for hoses, pipes, and pump equipment when dealing with flammable liquids?

What should be used for hoses, pipes, and pump equipment when dealing with flammable liquids?

Signup and view all the answers

Ensure that the oil compartment of the on-load tap-changer is correctly filled with _____ as per the instructions.

Ensure that the oil compartment of the on-load tap-changer is correctly filled with _____ as per the instructions.

Signup and view all the answers

What positions should both change-over selector contacts be in to check the on-load tap-changer's neutral position?

What positions should both change-over selector contacts be in to check the on-load tap-changer's neutral position?

Signup and view all the answers

What should the adjustment markings on the by-pass switch be aligned to?

What should the adjustment markings on the by-pass switch be aligned to?

Signup and view all the answers

Where should the tap position indicator be to check the motor-drive unit's neutral position?

Where should the tap position indicator be to check the motor-drive unit's neutral position?

Signup and view all the answers

Which assembly variant involves fitting the motor-drive unit directly beneath the on-load tap-changer?

Which assembly variant involves fitting the motor-drive unit directly beneath the on-load tap-changer?

Signup and view all the answers

What device must be switched off before performing a manual check?

What device must be switched off before performing a manual check?

Signup and view all the answers

The hand crank can be used to switch the on-load tap-changer's position from Neutral to 1L by turning it clockwise.

The hand crank can be used to switch the on-load tap-changer's position from Neutral to 1L by turning it clockwise.

Signup and view all the answers

What is the maximum number of tap-change operations allowed on the on-load tap-changer to avoid damage?

What is the maximum number of tap-change operations allowed on the on-load tap-changer to avoid damage?

Signup and view all the answers

What should be done before applying operating voltage to the on-load tap-changer?

What should be done before applying operating voltage to the on-load tap-changer?

Signup and view all the answers

What is the recommended maximum heating rate during the drying process of the on-load tap-changer?

What is the recommended maximum heating rate during the drying process of the on-load tap-changer?

Signup and view all the answers

The vacuum dry on-load tap-changer should be at a temperature between ____ and a maximum of ____.

The vacuum dry on-load tap-changer should be at a temperature between ____ and a maximum of ____.

Signup and view all the answers

Study Notes

Introduction

- The document provides instructions for the VACUTAP® RMV-II on-load tap-changer.

- Intended for trained and authorized personnel, it covers installation, commissioning, and monitoring.

- Includes safety instructions, technical data, and general product information.

Validity and Manufacturer

- Applies to standard designations of the VACUTAP® RMV-II (16L...N...16R).

- Manufactured by Reinhausen Manufacturing Inc., Humboldt, Tennessee, USA.

- Supporting technical data and drawings are provided upon order confirmation.

Notation Conventions

- Introduces the hazard communication system, indicating dangers and safety measures.

- Warnings are formatted to highlight dangers and required actions.

- Signal words categorize warnings by severity:

- DANGER: Death or serious injury likely.

- WARNING: Potential for death or serious injury.

- CAUTION: Risk of injury.

- NOTICE: Measures to prevent property damage.

Safety

- Focuses on appropriate use and regulations.

- Emphasizes fundamental safety instructions for personnel.

- Requires qualification and the use of personal protective equipment (PPE).

Product Description

- Detailed information about the on-load tap-changer function, design, and protective devices.

- Describes the motor-drive unit, its function, design, and protective features.

- Introduces the monitoring system (VIM) and its display/control functionalities.

Handling and Storage

- Instructions for the packaging, transport, and optimal storage of the device.

- Guidelines for unpacking and checking for transport damages.

Assembly and Commissioning

- Steps to fit the on-load tap-changer and motor-drive unit to a transformer.

- Checklists for assembly and operational trials.

- Instructions for high-voltage tests and safety checks before commissioning.

Maintenance and Monitoring

- Annual and occasional checks are required for operational monitoring.

- Emphasizes the importance of oil quality and functionality of the motor-drive unit.

- Details fault elimination procedures and maintenance intervals.

Technical Data

- Presents general data, operational temperature ranges, and maintenance guidelines.

- Specifies limit values for dielectric strength and acceptable water content in oil.### Warning Notices and Signal Words

- Pictograms serve to alert users to various dangers including danger points, electrical voltages, combustible substances, and tipping hazards.

- Essential for understanding procedures to avoid accidents and ensure safety when handling machinery.

Information and Instruction Systems

- Information is structured to enhance clarity on procedures.

- Single-step instructions focus on a single task with clear goals and possible outcomes.

- Multi-step instructions provide a sequence of actions, outlining each step with potential results.

Safety Guidelines

- Safety instructions emphasize proper installation, connection, commissioning, and monitoring of the product.

- Familiarization with the technical file is crucial for safe operation.

- Proper use of the on-load tap-changer is limited to electrical energy systems and must follow specified conditions to avoid hazards.

Appropriate Use and Operating Conditions

- Intended solely for the specified transformer in the order; serial numbers must match for safety.

- Can handle sinusoidal 50/60 Hz AC current and is designed to switch twice its rated through-current under certain conditions.

- Immediate avoidance of currents surpassing twice the rated through-current to prevent injury and damage.

Personal Protective Equipment (PPE)

- Use of PPE is mandatory to mitigate risks, including hard hats, safety shoes, and eye protection.

- Clothing should be close-fitting to prevent entanglement, with no loose parts or jewelry.

- Areas must be clean and well lit to prevent accidents.

Operational Safety

- Regular checks on operational reliability of equipment are necessary.

- Allowed operational conditions and approved materials specific to the product must be adhered to.

- Modifications or unapproved spare parts can cause hazards; only manufacturer-approved components should be used.

Personnel Qualification and Training

- Workers handling the product must have classifications such as electrically skilled or trained personnel.

- Operators must receive training on specific tasks and potential hazards.

- Maintenance should ideally be done by trained personnel from the manufacturer or authorized service.

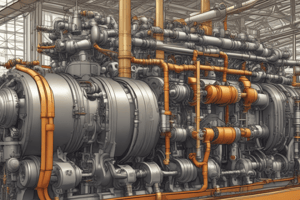

Product Overview

-

RMV-II on-load tap-changer utilized with oil-immersed transformers to adjust voltage or phase under load.

-

Features vacuum interrupters to eliminate contamination of oil and shutdown arcs during operation.

-

Packaging includes an oil compartment with multiple connections, ensuring moisture protection and readiness for installation.### VACUTAP RMV-II On-Load Tap-Changer

-

The VACUTAP RMV-II is a three-phase on-load tap-changer with full insulation between phases and to ground.

-

It consists of a tank with tap selector and change-over selector, by-pass switch, vacuum interrupters with monitoring system, motor-drive unit, and dehydrating breather.

Tap Changer Operation

- The tap changer operation is divided into three major functions: arc interruption and reclosing, selection of the next tap position, and operation of the change-over selector.

- The tap changer is operated using a motor-drive unit.

- The tap-change operation is activated by starting the motor-drive unit, and this operation is always completed regardless of any other control pulses emitted during the tap-change operation.

Design and Components

- The on-load tap-changer oil compartment has a vertical insulating plate per phase, with the vacuum interrupter mounted vertically on the front of the insulating plate.

- The by-pass switch is located on the opposite side of the insulating plate from the vacuum interrupter and is driven by the same drive shaft.

- Each phase of the on-load tap-changer consists of a tap selector and change-over selector, fitted on the rear of the on-load tap-changer oil compartment on an epoxy terminal board.

Motor-Drive Unit

- The motor-drive unit adjusts the operating position of on-load tap-changers in regulating transformers to the individual operating requirements.

- The motor-drive unit has a hand lamp, miniature circuit breaker, VIM-OK signal lamp, alarm signal lamp, LOCAL/REMOTE/AUTO rotary switch, RAISE/LOWER control switch, and snap latch.

- The motor-drive unit also has protective devices, including end stop device, device protecting against unintentional passage, motor protection device, and protection against accidental contact.

Monitoring System (VIM)

- The monitoring system is used to detect vacuum interrupter malfunctions.

- The monitoring system performs checks during every diverter switch operation and after every 2 tap-change operations for network applications and after every 32 tap-change operations for industrial applications.

- The monitoring system has displays and controls, including a green TEST push-button, green Power LED, and red RESET push-button.

Dehydrating Breather

- The dehydrating breather removes moisture from the air breathed into the on-load tap-changer.

- The dehydrating breather comprises a glass cylinder, connecting flange on top, breather, and protective grate with viewing windows.

Packaging, Transport, and Storage

- The products are sometimes supplied in a sealed packaging and sometimes in a dry state depending on requirements.

- The packaging is suitable for undamaged and fully functional means of transportation in compliance with local transportation laws and regulations.

- The packaged goods are protected from humidity using a desiccant, and the plastic foil is bonded after the desiccant is added.

- The packaging bears a signature with instructions for safe transport and correct storage, and includes symbols such as "Protect against moisture", "Top", "Fragile", and "Attach lifting gear here".

Introduction

- The document provides instructions for the VACUTAP® RMV-II on-load tap-changer.

- Intended for trained and authorized personnel, it covers installation, commissioning, and monitoring.

- Includes safety instructions, technical data, and general product information.

Validity and Manufacturer

- Applies to standard designations of the VACUTAP® RMV-II (16L...N...16R).

- Manufactured by Reinhausen Manufacturing Inc., Humboldt, Tennessee, USA.

- Supporting technical data and drawings are provided upon order confirmation.

Notation Conventions

- Introduces the hazard communication system, indicating dangers and safety measures.

- Warnings are formatted to highlight dangers and required actions.

- Signal words categorize warnings by severity:

- DANGER: Death or serious injury likely.

- WARNING: Potential for death or serious injury.

- CAUTION: Risk of injury.

- NOTICE: Measures to prevent property damage.

Safety

- Focuses on appropriate use and regulations.

- Emphasizes fundamental safety instructions for personnel.

- Requires qualification and the use of personal protective equipment (PPE).

Product Description

- Detailed information about the on-load tap-changer function, design, and protective devices.

- Describes the motor-drive unit, its function, design, and protective features.

- Introduces the monitoring system (VIM) and its display/control functionalities.

Handling and Storage

- Instructions for the packaging, transport, and optimal storage of the device.

- Guidelines for unpacking and checking for transport damages.

Assembly and Commissioning

- Steps to fit the on-load tap-changer and motor-drive unit to a transformer.

- Checklists for assembly and operational trials.

- Instructions for high-voltage tests and safety checks before commissioning.

Maintenance and Monitoring

- Annual and occasional checks are required for operational monitoring.

- Emphasizes the importance of oil quality and functionality of the motor-drive unit.

- Details fault elimination procedures and maintenance intervals.

Technical Data

- Presents general data, operational temperature ranges, and maintenance guidelines.

- Specifies limit values for dielectric strength and acceptable water content in oil.### Warning Notices and Signal Words

- Pictograms serve to alert users to various dangers including danger points, electrical voltages, combustible substances, and tipping hazards.

- Essential for understanding procedures to avoid accidents and ensure safety when handling machinery.

Information and Instruction Systems

- Information is structured to enhance clarity on procedures.

- Single-step instructions focus on a single task with clear goals and possible outcomes.

- Multi-step instructions provide a sequence of actions, outlining each step with potential results.

Safety Guidelines

- Safety instructions emphasize proper installation, connection, commissioning, and monitoring of the product.

- Familiarization with the technical file is crucial for safe operation.

- Proper use of the on-load tap-changer is limited to electrical energy systems and must follow specified conditions to avoid hazards.

Appropriate Use and Operating Conditions

- Intended solely for the specified transformer in the order; serial numbers must match for safety.

- Can handle sinusoidal 50/60 Hz AC current and is designed to switch twice its rated through-current under certain conditions.

- Immediate avoidance of currents surpassing twice the rated through-current to prevent injury and damage.

Personal Protective Equipment (PPE)

- Use of PPE is mandatory to mitigate risks, including hard hats, safety shoes, and eye protection.

- Clothing should be close-fitting to prevent entanglement, with no loose parts or jewelry.

- Areas must be clean and well lit to prevent accidents.

Operational Safety

- Regular checks on operational reliability of equipment are necessary.

- Allowed operational conditions and approved materials specific to the product must be adhered to.

- Modifications or unapproved spare parts can cause hazards; only manufacturer-approved components should be used.

Personnel Qualification and Training

- Workers handling the product must have classifications such as electrically skilled or trained personnel.

- Operators must receive training on specific tasks and potential hazards.

- Maintenance should ideally be done by trained personnel from the manufacturer or authorized service.

Product Overview

-

RMV-II on-load tap-changer utilized with oil-immersed transformers to adjust voltage or phase under load.

-

Features vacuum interrupters to eliminate contamination of oil and shutdown arcs during operation.

-

Packaging includes an oil compartment with multiple connections, ensuring moisture protection and readiness for installation.### VACUTAP RMV-II On-Load Tap-Changer

-

The VACUTAP RMV-II is a three-phase on-load tap-changer with full insulation between phases and to ground.

-

It consists of a tank with tap selector and change-over selector, by-pass switch, vacuum interrupters with monitoring system, motor-drive unit, and dehydrating breather.

Tap Changer Operation

- The tap changer operation is divided into three major functions: arc interruption and reclosing, selection of the next tap position, and operation of the change-over selector.

- The tap changer is operated using a motor-drive unit.

- The tap-change operation is activated by starting the motor-drive unit, and this operation is always completed regardless of any other control pulses emitted during the tap-change operation.

Design and Components

- The on-load tap-changer oil compartment has a vertical insulating plate per phase, with the vacuum interrupter mounted vertically on the front of the insulating plate.

- The by-pass switch is located on the opposite side of the insulating plate from the vacuum interrupter and is driven by the same drive shaft.

- Each phase of the on-load tap-changer consists of a tap selector and change-over selector, fitted on the rear of the on-load tap-changer oil compartment on an epoxy terminal board.

Motor-Drive Unit

- The motor-drive unit adjusts the operating position of on-load tap-changers in regulating transformers to the individual operating requirements.

- The motor-drive unit has a hand lamp, miniature circuit breaker, VIM-OK signal lamp, alarm signal lamp, LOCAL/REMOTE/AUTO rotary switch, RAISE/LOWER control switch, and snap latch.

- The motor-drive unit also has protective devices, including end stop device, device protecting against unintentional passage, motor protection device, and protection against accidental contact.

Monitoring System (VIM)

- The monitoring system is used to detect vacuum interrupter malfunctions.

- The monitoring system performs checks during every diverter switch operation and after every 2 tap-change operations for network applications and after every 32 tap-change operations for industrial applications.

- The monitoring system has displays and controls, including a green TEST push-button, green Power LED, and red RESET push-button.

Dehydrating Breather

- The dehydrating breather removes moisture from the air breathed into the on-load tap-changer.

- The dehydrating breather comprises a glass cylinder, connecting flange on top, breather, and protective grate with viewing windows.

Packaging, Transport, and Storage

- The products are sometimes supplied in a sealed packaging and sometimes in a dry state depending on requirements.

- The packaging is suitable for undamaged and fully functional means of transportation in compliance with local transportation laws and regulations.

- The packaged goods are protected from humidity using a desiccant, and the plastic foil is bonded after the desiccant is added.

- The packaging bears a signature with instructions for safe transport and correct storage, and includes symbols such as "Protect against moisture", "Top", "Fragile", and "Attach lifting gear here".

Introduction

- The document provides instructions for the VACUTAP® RMV-II on-load tap-changer.

- Intended for trained and authorized personnel, it covers installation, commissioning, and monitoring.

- Includes safety instructions, technical data, and general product information.

Validity and Manufacturer

- Applies to standard designations of the VACUTAP® RMV-II (16L...N...16R).

- Manufactured by Reinhausen Manufacturing Inc., Humboldt, Tennessee, USA.

- Supporting technical data and drawings are provided upon order confirmation.

Notation Conventions

- Introduces the hazard communication system, indicating dangers and safety measures.

- Warnings are formatted to highlight dangers and required actions.

- Signal words categorize warnings by severity:

- DANGER: Death or serious injury likely.

- WARNING: Potential for death or serious injury.

- CAUTION: Risk of injury.

- NOTICE: Measures to prevent property damage.

Safety

- Focuses on appropriate use and regulations.

- Emphasizes fundamental safety instructions for personnel.

- Requires qualification and the use of personal protective equipment (PPE).

Product Description

- Detailed information about the on-load tap-changer function, design, and protective devices.

- Describes the motor-drive unit, its function, design, and protective features.

- Introduces the monitoring system (VIM) and its display/control functionalities.

Handling and Storage

- Instructions for the packaging, transport, and optimal storage of the device.

- Guidelines for unpacking and checking for transport damages.

Assembly and Commissioning

- Steps to fit the on-load tap-changer and motor-drive unit to a transformer.

- Checklists for assembly and operational trials.

- Instructions for high-voltage tests and safety checks before commissioning.

Maintenance and Monitoring

- Annual and occasional checks are required for operational monitoring.

- Emphasizes the importance of oil quality and functionality of the motor-drive unit.

- Details fault elimination procedures and maintenance intervals.

Technical Data

- Presents general data, operational temperature ranges, and maintenance guidelines.

- Specifies limit values for dielectric strength and acceptable water content in oil.### Warning Notices and Signal Words

- Pictograms serve to alert users to various dangers including danger points, electrical voltages, combustible substances, and tipping hazards.

- Essential for understanding procedures to avoid accidents and ensure safety when handling machinery.

Information and Instruction Systems

- Information is structured to enhance clarity on procedures.

- Single-step instructions focus on a single task with clear goals and possible outcomes.

- Multi-step instructions provide a sequence of actions, outlining each step with potential results.

Safety Guidelines

- Safety instructions emphasize proper installation, connection, commissioning, and monitoring of the product.

- Familiarization with the technical file is crucial for safe operation.

- Proper use of the on-load tap-changer is limited to electrical energy systems and must follow specified conditions to avoid hazards.

Appropriate Use and Operating Conditions

- Intended solely for the specified transformer in the order; serial numbers must match for safety.

- Can handle sinusoidal 50/60 Hz AC current and is designed to switch twice its rated through-current under certain conditions.

- Immediate avoidance of currents surpassing twice the rated through-current to prevent injury and damage.

Personal Protective Equipment (PPE)

- Use of PPE is mandatory to mitigate risks, including hard hats, safety shoes, and eye protection.

- Clothing should be close-fitting to prevent entanglement, with no loose parts or jewelry.

- Areas must be clean and well lit to prevent accidents.

Operational Safety

- Regular checks on operational reliability of equipment are necessary.

- Allowed operational conditions and approved materials specific to the product must be adhered to.

- Modifications or unapproved spare parts can cause hazards; only manufacturer-approved components should be used.

Personnel Qualification and Training

- Workers handling the product must have classifications such as electrically skilled or trained personnel.

- Operators must receive training on specific tasks and potential hazards.

- Maintenance should ideally be done by trained personnel from the manufacturer or authorized service.

Product Overview

-

RMV-II on-load tap-changer utilized with oil-immersed transformers to adjust voltage or phase under load.

-

Features vacuum interrupters to eliminate contamination of oil and shutdown arcs during operation.

-

Packaging includes an oil compartment with multiple connections, ensuring moisture protection and readiness for installation.### VACUTAP RMV-II On-Load Tap-Changer

-

The VACUTAP RMV-II is a three-phase on-load tap-changer with full insulation between phases and to ground.

-

It consists of a tank with tap selector and change-over selector, by-pass switch, vacuum interrupters with monitoring system, motor-drive unit, and dehydrating breather.

Tap Changer Operation

- The tap changer operation is divided into three major functions: arc interruption and reclosing, selection of the next tap position, and operation of the change-over selector.

- The tap changer is operated using a motor-drive unit.

- The tap-change operation is activated by starting the motor-drive unit, and this operation is always completed regardless of any other control pulses emitted during the tap-change operation.

Design and Components

- The on-load tap-changer oil compartment has a vertical insulating plate per phase, with the vacuum interrupter mounted vertically on the front of the insulating plate.

- The by-pass switch is located on the opposite side of the insulating plate from the vacuum interrupter and is driven by the same drive shaft.

- Each phase of the on-load tap-changer consists of a tap selector and change-over selector, fitted on the rear of the on-load tap-changer oil compartment on an epoxy terminal board.

Motor-Drive Unit

- The motor-drive unit adjusts the operating position of on-load tap-changers in regulating transformers to the individual operating requirements.

- The motor-drive unit has a hand lamp, miniature circuit breaker, VIM-OK signal lamp, alarm signal lamp, LOCAL/REMOTE/AUTO rotary switch, RAISE/LOWER control switch, and snap latch.

- The motor-drive unit also has protective devices, including end stop device, device protecting against unintentional passage, motor protection device, and protection against accidental contact.

Monitoring System (VIM)

- The monitoring system is used to detect vacuum interrupter malfunctions.

- The monitoring system performs checks during every diverter switch operation and after every 2 tap-change operations for network applications and after every 32 tap-change operations for industrial applications.

- The monitoring system has displays and controls, including a green TEST push-button, green Power LED, and red RESET push-button.

Dehydrating Breather

- The dehydrating breather removes moisture from the air breathed into the on-load tap-changer.

- The dehydrating breather comprises a glass cylinder, connecting flange on top, breather, and protective grate with viewing windows.

Packaging, Transport, and Storage

- The products are sometimes supplied in a sealed packaging and sometimes in a dry state depending on requirements.

- The packaging is suitable for undamaged and fully functional means of transportation in compliance with local transportation laws and regulations.

- The packaged goods are protected from humidity using a desiccant, and the plastic foil is bonded after the desiccant is added.

- The packaging bears a signature with instructions for safe transport and correct storage, and includes symbols such as "Protect against moisture", "Top", "Fragile", and "Attach lifting gear here".

Introduction

- The document provides instructions for the VACUTAP® RMV-II on-load tap-changer.

- Intended for trained and authorized personnel, it covers installation, commissioning, and monitoring.

- Includes safety instructions, technical data, and general product information.

Validity and Manufacturer

- Applies to standard designations of the VACUTAP® RMV-II (16L...N...16R).

- Manufactured by Reinhausen Manufacturing Inc., Humboldt, Tennessee, USA.

- Supporting technical data and drawings are provided upon order confirmation.

Notation Conventions

- Introduces the hazard communication system, indicating dangers and safety measures.

- Warnings are formatted to highlight dangers and required actions.

- Signal words categorize warnings by severity:

- DANGER: Death or serious injury likely.

- WARNING: Potential for death or serious injury.

- CAUTION: Risk of injury.

- NOTICE: Measures to prevent property damage.

Safety

- Focuses on appropriate use and regulations.

- Emphasizes fundamental safety instructions for personnel.

- Requires qualification and the use of personal protective equipment (PPE).

Product Description

- Detailed information about the on-load tap-changer function, design, and protective devices.

- Describes the motor-drive unit, its function, design, and protective features.

- Introduces the monitoring system (VIM) and its display/control functionalities.

Handling and Storage

- Instructions for the packaging, transport, and optimal storage of the device.

- Guidelines for unpacking and checking for transport damages.

Assembly and Commissioning

- Steps to fit the on-load tap-changer and motor-drive unit to a transformer.

- Checklists for assembly and operational trials.

- Instructions for high-voltage tests and safety checks before commissioning.

Maintenance and Monitoring

- Annual and occasional checks are required for operational monitoring.

- Emphasizes the importance of oil quality and functionality of the motor-drive unit.

- Details fault elimination procedures and maintenance intervals.

Technical Data

- Presents general data, operational temperature ranges, and maintenance guidelines.

- Specifies limit values for dielectric strength and acceptable water content in oil.### Warning Notices and Signal Words

- Pictograms serve to alert users to various dangers including danger points, electrical voltages, combustible substances, and tipping hazards.

- Essential for understanding procedures to avoid accidents and ensure safety when handling machinery.

Information and Instruction Systems

- Information is structured to enhance clarity on procedures.

- Single-step instructions focus on a single task with clear goals and possible outcomes.

- Multi-step instructions provide a sequence of actions, outlining each step with potential results.

Safety Guidelines

- Safety instructions emphasize proper installation, connection, commissioning, and monitoring of the product.

- Familiarization with the technical file is crucial for safe operation.

- Proper use of the on-load tap-changer is limited to electrical energy systems and must follow specified conditions to avoid hazards.

Appropriate Use and Operating Conditions

- Intended solely for the specified transformer in the order; serial numbers must match for safety.

- Can handle sinusoidal 50/60 Hz AC current and is designed to switch twice its rated through-current under certain conditions.

- Immediate avoidance of currents surpassing twice the rated through-current to prevent injury and damage.

Personal Protective Equipment (PPE)

- Use of PPE is mandatory to mitigate risks, including hard hats, safety shoes, and eye protection.

- Clothing should be close-fitting to prevent entanglement, with no loose parts or jewelry.

- Areas must be clean and well lit to prevent accidents.

Operational Safety

- Regular checks on operational reliability of equipment are necessary.

- Allowed operational conditions and approved materials specific to the product must be adhered to.

- Modifications or unapproved spare parts can cause hazards; only manufacturer-approved components should be used.

Personnel Qualification and Training

- Workers handling the product must have classifications such as electrically skilled or trained personnel.

- Operators must receive training on specific tasks and potential hazards.

- Maintenance should ideally be done by trained personnel from the manufacturer or authorized service.

Product Overview

-

RMV-II on-load tap-changer utilized with oil-immersed transformers to adjust voltage or phase under load.

-

Features vacuum interrupters to eliminate contamination of oil and shutdown arcs during operation.

-

Packaging includes an oil compartment with multiple connections, ensuring moisture protection and readiness for installation.### VACUTAP RMV-II On-Load Tap-Changer

-

The VACUTAP RMV-II is a three-phase on-load tap-changer with full insulation between phases and to ground.

-

It consists of a tank with tap selector and change-over selector, by-pass switch, vacuum interrupters with monitoring system, motor-drive unit, and dehydrating breather.

Tap Changer Operation

- The tap changer operation is divided into three major functions: arc interruption and reclosing, selection of the next tap position, and operation of the change-over selector.

- The tap changer is operated using a motor-drive unit.

- The tap-change operation is activated by starting the motor-drive unit, and this operation is always completed regardless of any other control pulses emitted during the tap-change operation.

Design and Components

- The on-load tap-changer oil compartment has a vertical insulating plate per phase, with the vacuum interrupter mounted vertically on the front of the insulating plate.

- The by-pass switch is located on the opposite side of the insulating plate from the vacuum interrupter and is driven by the same drive shaft.

- Each phase of the on-load tap-changer consists of a tap selector and change-over selector, fitted on the rear of the on-load tap-changer oil compartment on an epoxy terminal board.

Motor-Drive Unit

- The motor-drive unit adjusts the operating position of on-load tap-changers in regulating transformers to the individual operating requirements.

- The motor-drive unit has a hand lamp, miniature circuit breaker, VIM-OK signal lamp, alarm signal lamp, LOCAL/REMOTE/AUTO rotary switch, RAISE/LOWER control switch, and snap latch.

- The motor-drive unit also has protective devices, including end stop device, device protecting against unintentional passage, motor protection device, and protection against accidental contact.

Monitoring System (VIM)

- The monitoring system is used to detect vacuum interrupter malfunctions.

- The monitoring system performs checks during every diverter switch operation and after every 2 tap-change operations for network applications and after every 32 tap-change operations for industrial applications.

- The monitoring system has displays and controls, including a green TEST push-button, green Power LED, and red RESET push-button.

Dehydrating Breather

- The dehydrating breather removes moisture from the air breathed into the on-load tap-changer.

- The dehydrating breather comprises a glass cylinder, connecting flange on top, breather, and protective grate with viewing windows.

Packaging, Transport, and Storage

- The products are sometimes supplied in a sealed packaging and sometimes in a dry state depending on requirements.

- The packaging is suitable for undamaged and fully functional means of transportation in compliance with local transportation laws and regulations.

- The packaged goods are protected from humidity using a desiccant, and the plastic foil is bonded after the desiccant is added.

- The packaging bears a signature with instructions for safe transport and correct storage, and includes symbols such as "Protect against moisture", "Top", "Fragile", and "Attach lifting gear here".

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz focuses on the operating instructions for the Vacutap RMV-II on-load tap-changer. Participants will learn about its features, functions, and proper usage guidelines. Ideal for individuals involved in transformer management and maintenance.