Podcast Beta

Questions and Answers

What is the primary purpose of the technical document discussed?

Which of the following is a requirement for individuals using the technical file?

Where can further information on the VACUTAP® RMV-II be obtained?

What is indicated by the signal word 'WARNING' in the hazard communication system?

Signup and view all the answers

Which type of information does the technical file deem incomplete without supporting documents?

Signup and view all the answers

What format is used for embedded warnings in the document?

Signup and view all the answers

What should be maintained for future reference according to the document?

Signup and view all the answers

Which of the following accurately describes the validity section of the document?

Signup and view all the answers

What could be the consequence of using unauthorized auxiliary materials?

Signup and view all the answers

Which qualification does an electrically skilled person NOT need to have?

Signup and view all the answers

What is a potential risk of modifying the product without manufacturer consultation?

Signup and view all the answers

Who is responsible for ensuring that personnel are sufficiently qualified?

Signup and view all the answers

Which of the following statements regarding spare parts is correct?

Signup and view all the answers

What distinguishes an electrically trained person from an electrically skilled person?

Signup and view all the answers

What type of hoses, pipes, and pump equipment is acceptable for use?

Signup and view all the answers

What is NOT a requirement for an electrically skilled person?

Signup and view all the answers

What is required to ensure that the on-load tap-changer does not present any danger during its service life?

Signup and view all the answers

Which of the following conditions must NOT be exceeded during the operation of the on-load tap-changer?

Signup and view all the answers

What is the maximum permitted short-term increase in rated step voltage Uir for the on-load tap-changer?

Signup and view all the answers

Which type of clothing poses an increased risk during the operation of the on-load tap-changer?

Signup and view all the answers

When operating the on-load tap-changer, who is allowed to perform necessary work?

Signup and view all the answers

What is the main purpose of the fundamental safety instructions provided for the on-load tap-changer?

Signup and view all the answers

Which is a requirement regarding the use of the equipment and special tools delivered with the on-load tap-changer?

Signup and view all the answers

What happens if the on-load tap-changer is operated outside the specified electrical operating conditions?

Signup and view all the answers

What should be done if mineral insulating oil does not meet the specified limit values?

Signup and view all the answers

Which button should be pressed to reset the alarm status after a fault is detected in the motor-drive unit?

Signup and view all the answers

During occasional visual checks, which of the following is NOT a point of concern?

Signup and view all the answers

What is a critical precautionary note regarding working with the on-load tap-changer?

Signup and view all the answers

What is the role of the monitoring system's green TEST push-button during tap change operations?

Signup and view all the answers

In the event of an error, which sequence correctly describes returning the on-load tap-changer to its starting position?

Signup and view all the answers

What is the proper procedure for checking the return to starting position of the on-load tap-changer?

Signup and view all the answers

For effective operation, which process should be included in the annual checks of the transformer?

Signup and view all the answers

What is the primary function of the by-pass switch during the tap changing operation?

Signup and view all the answers

Which component is NOT part of the RMV-II on-load tap changer design?

Signup and view all the answers

How does the change-over selector function in relation to the tap positions?

Signup and view all the answers

What initiates the operation of the vacuum interrupter in the tap change process?

Signup and view all the answers

What characteristic distinguishes the RMV-II on-load tap changer from other designs?

Signup and view all the answers

What role does the motor-drive unit play in the tap changing operation?

Signup and view all the answers

During a tap change operation, the sequence of opening and closing the by-pass switch and vacuum interrupter occurs in which order?

Signup and view all the answers

What is the purpose of the vertical insulating plate in the on-load tap changer design?

Signup and view all the answers

To switch from Neutral N to 1L using the hand crank, it requires 7.5 clockwise revolutions.

Signup and view all the answers

During the changeover to 1R, the change-over selector moves from B to A.

Signup and view all the answers

After changing to the new operating position 1L, the tap selector must move from 11 to M.

Signup and view all the answers

The by-pass switch opens before the vacuum interrupter in all tap changing operations.

Signup and view all the answers

It is necessary to check that the mobile contacts of the tap selector and change-over selector run smoothly and freely during operations.

Signup and view all the answers

The tap selector contact P1 is the furthest away from the terminal board.

Signup and view all the answers

Once the hand crank is used to return to Neutral, the tap selector moves from 4 to M.

Signup and view all the answers

It is acceptable to remove the hand crank and leave it unprotected after use.

Signup and view all the answers

Using a low temperature grease on screw joints helps prevent rust.

Signup and view all the answers

The clear plastic oil compartment should be filled with dirt to the fill level marks.

Signup and view all the answers

Only skilled technicians should perform work on the transformer.

Signup and view all the answers

Explosive gases can be present in the on-load tap-changer and its pipework system.

Signup and view all the answers

Personal protective equipment is optional when working on the transformer.

Signup and view all the answers

The oil compartment of the on-load tap-changer can be filled with any available oil.

Signup and view all the answers

The warning for the transformer mentions the risk of static charging.

Signup and view all the answers

Safety checks must be completed before starting up the transformer.

Signup and view all the answers

The on-load tap-changer is intended to be used with any type of transformer.

Signup and view all the answers

It is permissible to exceed the rated step voltage Uir by 15% for a short period.

Signup and view all the answers

Qualified personnel are required for all necessary work associated with the product.

Signup and view all the answers

Use of loosely worn clothing is recommended when operating the on-load tap-changer.

Signup and view all the answers

The on-load tap-changer can switch three times the rated through-current Ir at its rated step voltage Uir.

Signup and view all the answers

The serial numbers of the on-load tap-changer must match the accessories if supplied as a set.

Signup and view all the answers

Operating the on-load tap-changer outside specified electrical conditions can result in operational disruptions.

Signup and view all the answers

It is unnecessary to adhere to the design data mentioned in the order confirmation during operation.

Signup and view all the answers

Only trained personnel familiar with safety regulations should perform high voltage tests on transformers.

Signup and view all the answers

It is acceptable to perform high voltage tests on transformers with the motor-drive unit door open.

Signup and view all the answers

Ground connections on the motor-drive protective housing should be free of paint before testing.

Signup and view all the answers

All electronic components should remain connected during high voltage testing to prevent damage from overvoltage.

Signup and view all the answers

The tap position indicator should be in Neutral before disassembling the transformer for transport.

Signup and view all the answers

Hot surfaces and sparks are permitted near transformers during transportation as long as no external sources of ignition are present.

Signup and view all the answers

Leads used for testing should be left connected during the high voltage test as they do not affect the results.

Signup and view all the answers

When transporting a transformer, devices with a withstand voltage of less than 1,000 V should remain connected.

Signup and view all the answers

The maximum permitted measured current for an empty oil compartment during DC resistance measurement is $50 A$ DC.

Signup and view all the answers

The terminal board of the on-load tap-changer can withstand a maximum differential pressure of $1241 mbar$.

Signup and view all the answers

The vacuum drying process for the on-load tap-changer must be performed at a residual pressure no greater than $10^{-3} bar$.

Signup and view all the answers

The drying process for the on-load tap-changer should always be carried out at a temperature of $110 °C$ or higher.

Signup and view all the answers

The on-load tap-changer and transformer gas spaces should not be connected during the drying process.

Signup and view all the answers

A minimum drying period of $20$ hours is required while pre-drying the on-load tap-changer in circulating air.

Signup and view all the answers

On-load tap-changer accessories must be removed before the drying process to prevent damage.

Signup and view all the answers

The on-load tap-changer can be operated under full vacuum without any limitations.

Signup and view all the answers

Study Notes

Technical File Overview

- Contains technical data for product selection, safety instructions, and general information.

- Intended for trained and authorized personnel only.

- Valid for the VACUTAP® RMV-II on-load tap-changer; specific designs cover positions 16L to 16R.

Manufacturer Information

- Manufactured by Reinhausen Manufacturing Inc., located in Humboldt, Tennessee, USA.

- Contact via phone, fax, or email for further inquiries or technical documentation.

Completeness of Technical File

- Supporting documents are necessary for completeness, provided with order confirmation and delivery.

Safety Protocols

- Keep the technical file and all documents accessible for future reference.

- Identifies different hazard communication systems, including warnings and signal words:

- DANGER: Indicates risk of death or serious injury.

- WARNING: Indicates risk of severe injury.

- CAUTION: Indicates potential for injury.

Operating Conditions

- Designed for sinusoidal 50/60 Hz AC current; can switch double the rated through-current at the rated step voltage.

- Short-term exceedance of rated step voltage by up to 10% is allowed, provided through-current limits are not breached.

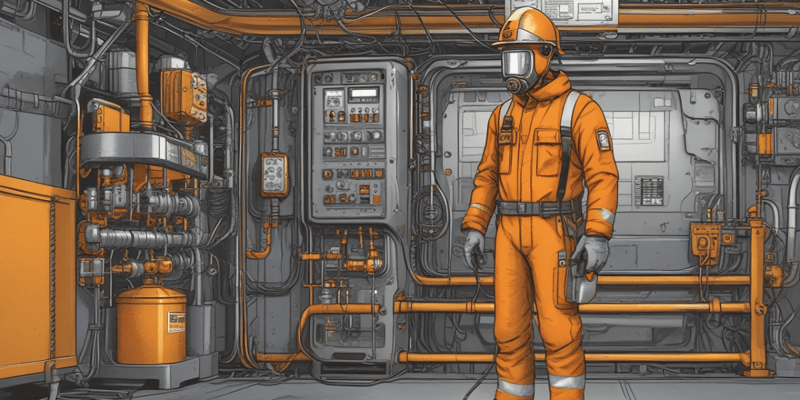

Personal Protective Equipment (PPE)

- Emphasizes the importance of PPE to prevent risk of accidents when operating machinery.

- Adequate clothing is crucial to avoid becoming entangled in moving parts.

Auxiliary Materials

- Use only approved auxiliary and operating materials to prevent malfunctions and injuries.

- Contact the manufacturer for approval on any non-standard materials.

Personnel Qualification

- Assembled and operated by qualified personnel only:

- Electrically skilled individuals must identify dangers and possess compliance knowledge.

- Electrically trained personnel must work under the supervision of skilled counterparts.

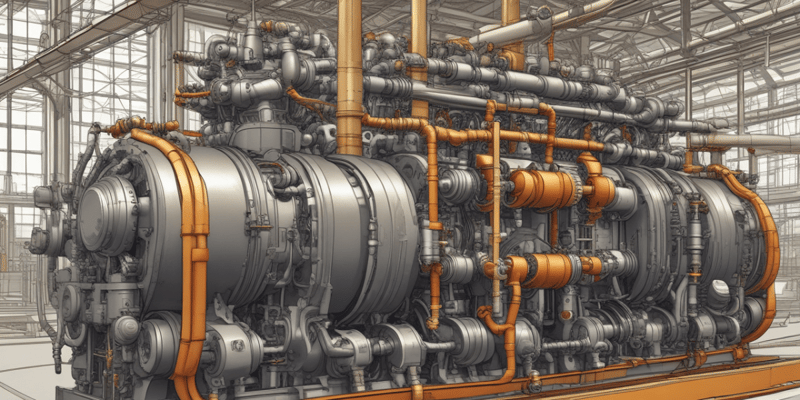

Product Description

- The RMV-II on-load tap-changer consists of:

- Tank, tap selector, change-over selector, by-pass switch, vacuum interrupters, motor-drive unit, dehydrating breather.

- Features full insulation between phases and to ground for safety during use.

Tap-Changer Operation

- Operates sequentially with a motor-drive unit.

- Current is routed through vacuum interrupters during position changes to ensure safe operation.

Monitoring During Operation

- Regular checks of the motor-drive unit and prerequisite safety measures are detailed in the operating instructions.

- Visual inspections should focus on seals, functionality of electrical components, and indicators of proper operation.

Fault Elimination Guidelines

- Highlights dangers related to explosive gases and hot oil during operations.

- Emphasizes adherence to safety protocols to minimize risk of serious injury or fatal accidents.

Measurement Guidelines for On-Load Tap-Changer

- Measured current must be below maximum thresholds: 10 A DC when uninterrupted and 50 A DC under various oil conditions.

- Ensure proper oil filling during resistance measurements on transformers to adhere to safety standards.

Drying Process for On-Load Tap-Changer

- Remove accessories (dehydrating breather, pressure relief devices) before drying to prevent damage from pressure changes.

- Connect oil compartments between the on-load tap-changer and transformer via vent plug during drying.

- Heat the on-load tap-changer at atmospheric pressure to 110 °C, increasing temperature at 10 K/h.

- Pre-dry with circulating air at 110 °C for at least 20 hours; proceed with vacuum drying at 105 °C to 110 °C.

- Maintain a residual pressure of 10-3 bar [0.75 Torr/0.015 psi] during vacuum drying, lasting at least 50 hours.

- Break vacuum with dry, inert gas to avoid moisture contamination; ensure terminal boards can withstand 1241 mbar [931 Torr/18 psi] pressure.

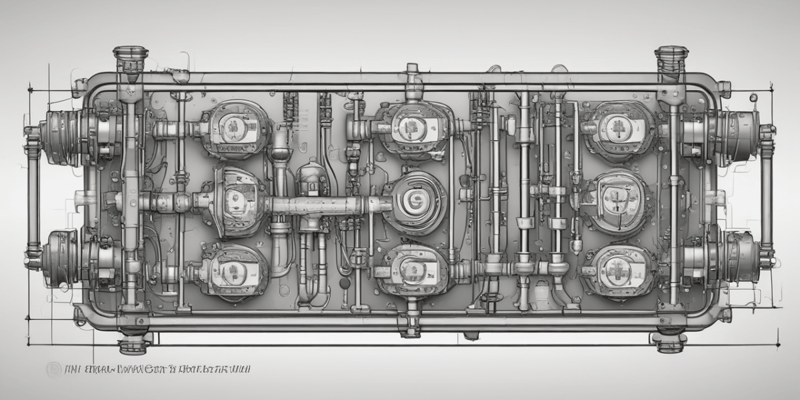

Switching Process

- Utilize a hand crank for operation changes from Neutral to designated positions.

- Observe the sequential operation: bypass switches open, vacuum interrupters activate, and tap selectors move accordingly.

- Ensure that mobile contacts of tap selectors operate smoothly to minimize mechanical stress.

Safety Precautions

- Personal protective equipment is crucial to avoid accidents or injuries while working on tap-changers.

- Use high-temperature greases to prevent rust and facilitate easy disassembly of joints.

- Follow proper operational and safety guidelines to prevent environmental damage and ensure personal safety during installation and maintenance.

Operating Conditions and Specifications

- On-load tap-changer designed for sinusoidal 50/60 Hz AC current; can switch currents up to twice the rated capacity.

- Short-term exceedance of rated voltage (by 10%) permissible if rated current limits are not crossed.

- All related components (drive, relay, etc.) should match serial numbers when supplied as a complete set.

Assembly and Checks Post-operation

- Conduct thorough checks post-assembly before operational commencement using designated hand crank and checking positioning.

- Confirm smooth operation of by-pass and vacuum interrupters during functional checks.

- Close all protective housings adequately after operation and align oil compartments correctly.

Commissioning and Transport Safety

- Only authorized technicians should initiate transformer operations due to potential exposure to hazards (explosive gases, high-pressure systems).

- Conduct high-voltage tests with caution, ensuring proper ground connections and protective measures in place.

- Prepare transformers for transportation with essential safety equipment in readiness, ensuring tap position indicators are correctly set.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz focuses on the technical data and safety instructions related to the VACUTAP® RMV-II on-load tap-changer. It is intended for specially trained and authorized personnel, ensuring that the correct product is selected for respective applications. Understanding its standard position designations is crucial for effective operation.