Podcast

Questions and Answers

What is the primary focus of the presented material?

What is the primary focus of the presented material?

Who is the author of the material?

Who is the author of the material?

What specific area of civil engineering is highlighted in the material?

What specific area of civil engineering is highlighted in the material?

What can be primarily inferred about the content?

What can be primarily inferred about the content?

Signup and view all the answers

What is the likely use of this material?

What is the likely use of this material?

Signup and view all the answers

What is a specific element of Civil Engineering that this material addresses?

What is a specific element of Civil Engineering that this material addresses?

Signup and view all the answers

What type of professional would likely benefit most from this material?

What type of professional would likely benefit most from this material?

Signup and view all the answers

What aspect of the construction process is the content most pertinent to?

What aspect of the construction process is the content most pertinent to?

Signup and view all the answers

The content mainly suggests a focus on what level of civil engineering studies?

The content mainly suggests a focus on what level of civil engineering studies?

Signup and view all the answers

What is the primary purpose of the repeated presentation of "Civil Engineering by Sandeep Jyani Sir | Building Materials"?

What is the primary purpose of the repeated presentation of "Civil Engineering by Sandeep Jyani Sir | Building Materials"?

Signup and view all the answers

Study Notes

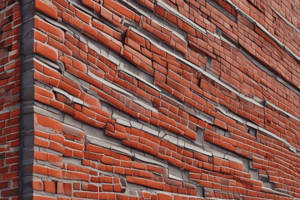

Brick

- Bricks are small rectangular blocks made of fired or sun-dried clay

- Used in construction

- Stretcher Face: the side face of the brick

- Header Face: the end surface of the brick

- Brick shape is rectangular, and size is convenient for one-hand handling

- Can be made of burnt clay, mixtures of sand and lime, or Portland cement concrete

- Clay bricks are economical and readily available

Size of Brick

- Standard Size: 19cm x 9cm x 9cm

- Nominal Size (with mortar): 20cm x 10cm x 10cm

- Conventional Size: 22.4 cm x 11.4 cm x 7.6 cm

- Country/Field Brick: 9" x 4.5" x 3"

Classification of Bricks

- Classified based on field practice

- Strength (e.g., Class 3.5-35 MPa)

- Use (e.g., Common Brick, Facing Brick, Engineering Brick)

- Types (e.g., Solid, Perforated, Hollow, Cellular)

Composition of Brick

- Silica: 50-60%

- Prevents cracking, shrinkage, and warping

- Imparts uniform shape; if in excess, reduces cohesion and makes bricks brittle

- Alumina: 20-30%

- Impacts plasticity, enabling easy molding

- If in excess, leads to shrinkage, warping, and brittleness

- Lime: 4-5%

- Prevents shrinkage; if in excess, causes melting during burning

- Oxides of Iron: 5-6%

- Helps silica and lime fuse, improving strength

- Gives reddish-brown colour

- Magnesia: 1%

- Prevents shrinkage and imparts yellowish tint

Harmful Ingredients in Brick

- Lime Slaking: Volume increase leads to cracking and disintegration

- Changes colour from red to yellow

- Iron Pyrites: Oxidation during burning causes crystallization and disintegration

- Brick may split into pieces

- Alkalies: Act as a flux during burning; excess causes bricks to fuse together

- Results in twisting, warping, efflorescence, and staining

- Pebbles/Stones: Lead to weak, porous bricks; reduce load-carrying capacity

- Organic/Vegetative Matter: Assists burning but if not completely burnt, gases form

- Causes voids, reducing load-carrying capacity

Manufacturing of Bricks

- Preparation of Clay (Unsoiling, Digging, Cleaning, Weathering, Blending, Tempering)

- Moulding

- Drying (Either natural or artificial. Bricks laid along their edge)

- Burning (at 1100°C in Clamps or Kilns)

Burning of Bricks

- Clamps: Trapezoidal ground section; fuelled by grass, rice husk, ash, wood, cow dung, coal, etc.

-

Kilns: Large ovens (intermittent or continuous) for burning

- i) Intermittent Kilns: Loading, burning, and unloading done sequentially

-

ii) Continuous Kilns: Bull trench, Hoffmann, Tunnel

- Bull Trench Kiln: Movable chimneys, different chambers

- Hoffmann Kiln: Fixed central chimney; multiple chambers

- Tunnel Kiln: Tunnel-shaped with stationary zones; loading, burning, unloading simultaneous

Quality/Testing of Bricks

- Dimension Test: Uniform shape and size

- Standard size: 19cm x 9cm x 9cm; with mortar: 20cm x 10cm x 10cm

- Sound Test: Clear metallic ringing sound when struck together

- Structure Test: Uniform homogenous structure, free from voids

- Absorption Test: Amount of water absorbed after 24 hours of immersion (20% for 1st class, 22% for 2nd class, 25% for 3rd class)

- Compressive Strength Test: Minimum compressive strength required for various classes

- Toughness Test: Should not break when dropped from 1m height

- Hardness/Abrasion Test: Should not show any impression from scratching with finger nails

- **Alkali Test:**Bricks should not show efflorescence or staining after 24 hours of water immersion

Defects of Bricks

- Overburning: Soft, molten mass; unsuitable for construction

- Underburning: High water absorption; low compressive strength

- Black Core: Darkening due to bituminous matter or carbon in insufficiently burnt bricks

- Chuffs: Deformation due to rain water falling on hot bricks

- Checks/Cracks: Lumps of lime or excess water; cause expansion and shrinkage

- Spots: Dark spots due to iron sulfide; not harmful but unsuitable for use in exposed areas

- Blisters: Broken blisters on surface due to air trapped during moulding

- Laminations: Thin laminas on brick faces, due to entrapped air. Weakness in structure.

Brick Masonry

- Stretcher: Longer side face of the brick

- Header: Shorter side face; used for hearting walls

- Closures: Bricks cut along the length: Queen closure (half/quarter), Bevelled closure, Mittered closure, King closure

- Bats: Bricks cut along the width: Half bat, Three-quarter bat, Bevelled bat

- Quoins: Exterior angles of walls greater than 90°

Bonding in Brick Masonry

-

English Bond: Alternate header and stretcher layers

- Minimum lap for stretcher is ¼ the length of the brick

- Flemish Bond: Alternate header and stretcher layers; breaks vertical alignment

- Stretcher Bond: Bricks laid along the stretcher; half bats are used to break vertical alignment

- Header Bond: Bricks laid along the header; quarter bats used to break vertical alignment

Some Important Clay Products

- Terracotta: A reddish-orange fired clay product.

- Uses: Hollow blocks for masonry; cornices, arches, statuettes. Most suitable for steel columns and beams.

- Different compositions are used based on application. Uses: sound insulation

- Porcelain: High-grade ceramic wares, white colour, zero water absorption, glazed surface

- Properties: Hard, dense, vitreous mass, good refractory material, good electric insulator.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz covers the fundamentals of bricks, including their composition, size, and classification. Learn about different types of bricks used in construction and their unique properties. Test your knowledge on standard, nominal, and conventional sizes as well as the materials that compose various brick types.