Podcast

Questions and Answers

What should be done prior to installing the regulator on a gas cylinder?

What should be done prior to installing the regulator on a gas cylinder?

- Briefly open the cylinder shut-off valve to blow out any foreign material (correct)

- Store and transport the acetylene cylinders in the horizontal position

- Check the contents in the tank by slowly opening the cylinder valve

- Connect the red hose with left-hand threads to the oxygen pressure regulator

What is the purpose of flashback arrestors in oxy-acetylene welding?

What is the purpose of flashback arrestors in oxy-acetylene welding?

- Reduce gas pressure

- Prevent flashback (correct)

- Increase gas flow rate

- Minimize gas leakage

What is the purpose of a 25-inch lens used in oxy-acetylene welding?

What is the purpose of a 25-inch lens used in oxy-acetylene welding?

- Prevention of gas leakage

- Enhancement of flame brightness

- Protection from flying sparks (correct)

- Regulation of gas flow

How is the shade of lens selected for gas welding traditionally?

How is the shade of lens selected for gas welding traditionally?

What is the purpose of torch lighters in oxy-acetylene welding?

What is the purpose of torch lighters in oxy-acetylene welding?

Study Notes

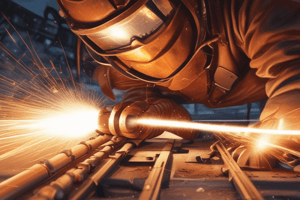

Oxy-Acetylene Welding Equipment Setup and Usage

- Oxy-acetylene welding equipment setup requires a systematic and definite order to avoid costly damage and ensure personnel safety.

- Gas cylinders, especially acetylene cylinders, should be stored and transported in the upright position to prevent fuel starvation and flashback in the system.

- Prior to installing the regulator on a gas cylinder, the cylinder shut-off valve should be briefly opened to blow out any foreign material that may be lodged in the outlet.

- The red hose with left-hand threads should be connected to the acetylene pressure regulator, and the green hose with right-hand threads should be connected to the oxygen pressure regulator.

- Flashback arrestors should be installed between the regulator and hose to prevent flashback, and fittings should be tightened only enough to prevent leakage.

- The oxygen cylinder valve should be slowly opened to check the contents in the tank, while the acetylene cylinder shutoff valve should be slowly opened just enough to get the required flow.

- A 25-inch lens, available with an elastic strap, provides protection from flying sparks and accepts a variety of standard shade and color lenses. It can be worn over prescription glasses.

- In the past, lens shade for gas welding was selected based on the brightness of the flame emitting from the torch, with the darkest shade showing a clear definition of the work being most desirable.

- A new green glass lens was developed in the late 1980s by TM Technologies, designed especially for aluminum oxy-fuel welding, eliminating the sodium orange flare completely and meeting ANSI Z87 1989 safety standards.

- Torch lighters, also called friction lighters or flint strikers, consist of a file-shaped piece of steel and a replaceable flint, producing a shower of sparks to light the fuel gas.

- The use of proper filler rod is crucial for oxyacetylene welding, adding reinforcement and desired properties to the finished weld. Rods may be classified as ferrous or non-ferrous, and their diameter is governed by the thickness of the metals to be joined.

- Welding rods are manufactured in standard 36-inch lengths and in diameters from 1/16 inch to 3/8 inch, and all filler rods should be cleaned prior to use.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Test your knowledge of oxy-acetylene welding equipment setup and usage with this quiz. Learn about the proper storage and transportation of gas cylinders, installation of regulators, selection of lens shades, use of flashback arrestors, and the importance of using proper filler rods. Master the systematic order required for setup and ensure safety and efficiency in oxy-acetylene welding.