Podcast

Questions and Answers

______ is crucial to avoid accidents like fires and explosions when working with oxy-acetylene cutting equipment.

______ is crucial to avoid accidents like fires and explosions when working with oxy-acetylene cutting equipment.

Safety

Ensure proper fittings and left-handed threads for ______ tank connections.

Ensure proper fittings and left-handed threads for ______ tank connections.

acetylene

Use the correct wrench sizes to avoid damaging fittings when setting up the ______ system.

Use the correct wrench sizes to avoid damaging fittings when setting up the ______ system.

torch

Check for leaks in the system by using ______ water.

Check for leaks in the system by using ______ water.

It is recommended to wear appropriate protective gear like jackets, welding caps, denim jeans, gloves, and eye protection when engaging in oxy-fuel ______.

It is recommended to wear appropriate protective gear like jackets, welding caps, denim jeans, gloves, and eye protection when engaging in oxy-fuel ______.

Recommended safety gear for cutting applications includes shade five to six goggles, IR5 safety glasses, and a ______ shield.

Recommended safety gear for cutting applications includes shade five to six goggles, IR5 safety glasses, and a ______ shield.

Different types of flames in welding include neutral flame, carburizing flame (too much fuel), and ______ flame (too much oxygen).

Different types of flames in welding include neutral flame, carburizing flame (too much fuel), and ______ flame (too much oxygen).

Maintaining a safe distance while cutting to prevent impurities from being sucked into the torch tip due to the ______ effect.

Maintaining a safe distance while cutting to prevent impurities from being sucked into the torch tip due to the ______ effect.

Tips for cutting with a torch include cutting with intention by following a scribed line and using a stable hand position for clean, precise ______.

Tips for cutting with a torch include cutting with intention by following a scribed line and using a stable hand position for clean, precise ______.

Using a scarfing tip for flush cuts or rivet cutting, where the torch is held at an ______ to avoid welding the material back together.

Using a scarfing tip for flush cuts or rivet cutting, where the torch is held at an ______ to avoid welding the material back together.

Study Notes

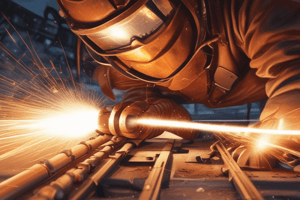

- Tutorial on oxy-acetylene cutting covering safety features, selecting appropriate tips for cutting different materials, and setting up the system.

- Emphasis on safety to avoid accidents like fires and explosions, including not using petroleum products near oxygen sources.

- Steps to hook up oxygen and acetylene tanks, ensuring proper fittings and left-handed threads for acetylene.

- Importance of using the correct wrench sizes to avoid damaging fittings, and not using Teflon tape on acetylene connections.

- Instructions on setting up the torch, selecting the right tip based on material thickness, and adjusting pressure for oxygen and acetylene accordingly.

- Tips on pressurizing the system, checking for leaks using soapy water, and ensuring all connections are secure.

- Information on acetylene tanks being filled by weight, the need to run them upright, and potential risks of withdrawing liquid acetone by running at pressures higher than 15 psi.

- Discussion on flashback arrestors and check valves to prevent flames from traveling back into the lines.

- Safety precautions recommended while oxy-fuel cutting, including wearing appropriate protective gear like jackets, welding caps, denim jeans, gloves, and eye protection.

- Necessity of using natural fibers in clothing to avoid synthetic materials melting onto the skin during cutting operations.- Arc flash from bright light can cause keratitis, also known as welders' flash, which can happen without the person realizing.

- Recommended safety gear for cutting applications includes shade five to six goggles, IR5 safety glasses, and a face shield.

- Different types of flames in welding include neutral flame, carburizing flame (too much fuel), and oxidizing flame (too much oxygen).

- Tips for cleaning a welding torch tip include using a file to remove debris and cleaning out each port carefully.

- Maintaining a safe distance while cutting to prevent impurities from being sucked into the torch tip due to the venturi effect.

- Tips for cutting with a torch include cutting with intention by following a scribed line and using a stable hand position for clean, precise cuts.

- Swapping out torch tips for different material thicknesses requires adjusting the tip size and checking working pressures accordingly.

- Using a scarfing tip for flush cuts or rivet cutting, where the torch is held at an angle to avoid welding the material back together.

- Setting up and using a rosebud for preheating and post-heating applications, ensuring the correct tip size based on the acetylene tank capacity.

- Proper safety practices when using a rosebud include checking O-rings, setting working pressures, and bleeding the lines to prevent accidents.

- Steps for wrapping up oxy-acetylene welding equipment involve shutting off tanks, bleeding the lines, detaching the torch, and coiling the hoses properly for storage.- OSHA regulations require that if a gas system will be left set up for more than 24 hours, the entire system needs to be broken down and the gas cylinders need to be separated to prevent any issues.

- When handling gas bottles, always ensure that they have a cap on them or are secured to an appropriate cart to prevent accidents.

- Gas cylinders can be chained to a column, put in a bottle rack, or secured on an appropriate cart for lifting, but they should never be left freestanding.

- If there is no cart or column available, lean the gas cylinder on its side and wedge it securely to prevent rolling.

- When removing gas cylinders, remember that they have left-handed threads, so you need to turn them in the opposite direction (righty to loosen).

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Learn about safety measures, proper setup, and tips for oxy-acetylene cutting, including selecting tips, adjusting pressure, and using the correct gear to prevent accidents. Understand the importance of handling gas cylinders, maintaining equipment, and following OSHA regulations for safe usage.