Podcast

Questions and Answers

What does the rupture disk respond to?

What does the rupture disk respond to?

A defined overpressure in the oil compartment of the on-load tap-changer.

The MPREC® pressure relief device is supplied with the rupture disk.

The MPREC® pressure relief device is supplied with the rupture disk.

False

What does the tap-change supervisory device monitor?

What does the tap-change supervisory device monitor?

It monitors both the drive shaft between on-load tap-changer(s) and motor-drive unit and the correct switching of the diverter switch.

What does the temperature monitoring system track?

What does the temperature monitoring system track?

Signup and view all the answers

What is one component of the drive shaft?

What is one component of the drive shaft?

Signup and view all the answers

The drive shaft consists of a ______ tube.

The drive shaft consists of a ______ tube.

Signup and view all the answers

The drive shaft configuration requires the use of an intermediate bearing only when exceeding 2472 mm.

The drive shaft configuration requires the use of an intermediate bearing only when exceeding 2472 mm.

Signup and view all the answers

What must be done to ensure the safety during commissioning?

What must be done to ensure the safety during commissioning?

Signup and view all the answers

What should be checked regarding the insulating fluid during commissioning?

What should be checked regarding the insulating fluid during commissioning?

Signup and view all the answers

What is the purpose of the signaling contact for minimum insulating fluid fill level?

What is the purpose of the signaling contact for minimum insulating fluid fill level?

Signup and view all the answers

What is the main purpose of the VACUTAP® VM®?

What is the main purpose of the VACUTAP® VM®?

Signup and view all the answers

The product can be used with an oil filter unit.

The product can be used with an oil filter unit.

Signup and view all the answers

What must match if the on-load tap-changer and its accessories are supplied as a set?

What must match if the on-load tap-changer and its accessories are supplied as a set?

Signup and view all the answers

The hand crank can be used to operate the motor-drive unit before disconnecting the transformer.

The hand crank can be used to operate the motor-drive unit before disconnecting the transformer.

Signup and view all the answers

The manufacturer of the VACUTAP® VM® is _.

The manufacturer of the VACUTAP® VM® is _.

Signup and view all the answers

When is the use of the hand crank permitted for operating the motor-drive unit?

When is the use of the hand crank permitted for operating the motor-drive unit?

Signup and view all the answers

Which of the following statements about warning notices is correct?

Which of the following statements about warning notices is correct?

Signup and view all the answers

What should you do if the hand crank is difficult to move?

What should you do if the hand crank is difficult to move?

Signup and view all the answers

What is the contact information for Maschinenfabrik Reinhausen GmbH?

What is the contact information for Maschinenfabrik Reinhausen GmbH?

Signup and view all the answers

An operation is considered an emergency operation if a tap-change operation is absolutely necessary when a transformer is ______.

An operation is considered an emergency operation if a tap-change operation is absolutely necessary when a transformer is ______.

Signup and view all the answers

What should be worn to prevent injuries during operation and maintenance?

What should be worn to prevent injuries during operation and maintenance?

Signup and view all the answers

What must be checked if the protective relay has tripped?

What must be checked if the protective relay has tripped?

Signup and view all the answers

What should be ensured regarding the work area?

What should be ensured regarding the work area?

Signup and view all the answers

The product is designed solely for use in electrical energy systems.

The product is designed solely for use in electrical energy systems.

Signup and view all the answers

What action should be taken if insulating fluid is leaking from the on-load tap-changer head cover?

What action should be taken if insulating fluid is leaking from the on-load tap-changer head cover?

Signup and view all the answers

Which of the following is considered inappropriate use of the product?

Which of the following is considered inappropriate use of the product?

Signup and view all the answers

Which of the following is a warning related to the operation of the motor-drive unit?

Which of the following is a warning related to the operation of the motor-drive unit?

Signup and view all the answers

Condensate in the protective housing of the motor-drive unit is acceptable.

Condensate in the protective housing of the motor-drive unit is acceptable.

Signup and view all the answers

What must be done after a tap-change supervisory device has been activated?

What must be done after a tap-change supervisory device has been activated?

Signup and view all the answers

What must be regularly checked to ensure safe operation of the product?

What must be regularly checked to ensure safe operation of the product?

Signup and view all the answers

Highly flammable or explosive gases can be present in areas where maintenance should occur.

Highly flammable or explosive gases can be present in areas where maintenance should occur.

Signup and view all the answers

What condition must the product be operated in?

What condition must the product be operated in?

Signup and view all the answers

Which type of materials should only be used as auxiliary materials?

Which type of materials should only be used as auxiliary materials?

Signup and view all the answers

What is required for personnel responsible for maintaining the product?

What is required for personnel responsible for maintaining the product?

Signup and view all the answers

Who should modifications to the product be discussed with?

Who should modifications to the product be discussed with?

Signup and view all the answers

What is the purpose of personal protective equipment?

What is the purpose of personal protective equipment?

Signup and view all the answers

What must be worn to minimize risks to health during work?

What must be worn to minimize risks to health during work?

Signup and view all the answers

What is the function of the protective relay in an on-load tap-changer?

What is the function of the protective relay in an on-load tap-changer?

Signup and view all the answers

What is used to protect the on-load tap-changer from impermissible pressure increases?

What is used to protect the on-load tap-changer from impermissible pressure increases?

Signup and view all the answers

Which of the following best describes an on-load tap-changer?

Which of the following best describes an on-load tap-changer?

Signup and view all the answers

The person responsible for assembly and maintenance must ensure personnel are sufficiently qualified in __________.

The person responsible for assembly and maintenance must ensure personnel are sufficiently qualified in __________.

Signup and view all the answers

What should you do if the pressure monitoring device tripped?

What should you do if the pressure monitoring device tripped?

Signup and view all the answers

What is the first step to take if the sensor is in the OFF position?

What is the first step to take if the sensor is in the OFF position?

Signup and view all the answers

What should you contact Maschinenfabrik Reinhausen about if the sensor is in OFF position?

What should you contact Maschinenfabrik Reinhausen about if the sensor is in OFF position?

Signup and view all the answers

What is a danger when working on the on-load tap-changer?

What is a danger when working on the on-load tap-changer?

Signup and view all the answers

It is safe to switch on the transformer immediately after the pressure monitoring device trips.

It is safe to switch on the transformer immediately after the pressure monitoring device trips.

Signup and view all the answers

What should you check for annually as part of the inspection?

What should you check for annually as part of the inspection?

Signup and view all the answers

What action should be taken after every 300,000 switching operations of the on-load tap-changer?

What action should be taken after every 300,000 switching operations of the on-load tap-changer?

Signup and view all the answers

What should be done if the dielectric strength and water content are not compliant?

What should be done if the dielectric strength and water content are not compliant?

Signup and view all the answers

The maintenance intervals for the on-load tap-changer do not depend on whether there is an MR monitoring system in place.

The maintenance intervals for the on-load tap-changer do not depend on whether there is an MR monitoring system in place.

Signup and view all the answers

What should be checked every two years for on-load tap-changers?

What should be checked every two years for on-load tap-changers?

Signup and view all the answers

What must be ensured before operating the motor-drive unit?

What must be ensured before operating the motor-drive unit?

Signup and view all the answers

Study Notes

Introduction

- Technical file contains operational monitoring, fault elimination, and maintenance procedures.

- Intended for trained and authorized personnel only.

- Supporting documents include unpacking instructions, connection diagrams, and dimensional drawings.

Manufacturer Information

- Maschinenfabrik Reinhausen GmbH, Regensburg, Germany.

- Contact: +49 941 4090-0, [email protected], www.reinhausen.com.

Safety Instructions

- Read and familiarize with safety instructions to avoid risks during use.

- Product is designed for on-load tap-changing in electrical energy systems, maintaining load flow.

Appropriate Use

- Only use with specified transformer/motor-drive unit.

- Must match serial numbers for tap-changer and accessories.

- Operate according to technical specifications and employ qualified personnel.

- Designed for sinusoidal 50/60 Hz AC with specific current and voltage ratings.

Inappropriate Use

- Using the product outside specified design conditions is prohibited.

- Risks of short circuits and electrical overloads can lead to injury and damage.

Fundamental Safety Guidelines

- Personal protective equipment (PPE) such as helmets and gloves is essential.

- Keep work area clean and well-lit to prevent accidents.

- Regularly check the operational condition and safety equipment.

- Avoid installation or maintenance in explosive atmospheres.

Ambient Conditions and Materials

- Operate only under specified ambient conditions to ensure safety.

- Use only manufacturer-approved materials and fluids to prevent malfunctions.

Modifications and Conversions

- Unauthorized changes can result in personal injury and operational faults.### Spare Parts and Modification

- Consult Maschinenfabrik Reinhausen GmbH before modifying any product.

- Using unapproved spare parts can cause physical injury, product damage, and malfunctions.

- Only approved spare parts from Maschinenfabrik Reinhausen GmbH should be used.

Personnel Qualifications

- Assembly, commissioning, operation, maintenance, and inspection must be performed by qualified personnel.

- Electrically Skilled Person: Has technical qualifications, able to identify and avoid hazards, works on electrical systems, trained for specific environments, must comply with safety regulations.

- Electrically Trained Person: Receives guidance from an electrically skilled person, works under their supervision, understands typical dangers and safety measures.

- Operator: Utilizes the product as instructed, must receive training on specific tasks and potential hazards.

- Maintenance, repairs, and retrofitting should be performed by the Technical Service department of Maschinenfabrik Reinhausen GmbH or by authorized personnel.

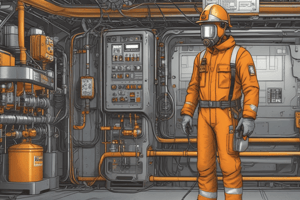

Personal Protective Equipment (PPE)

- Wear appropriate PPE to minimize health risks.

- Ensure PPE is undamaged; follow workplace information regarding PPE.

- Types of PPE include:

- Protective Clothing: Close-fitting to prevent catching on moving parts.

- Safety Shoes: Protect against falling objects and slipping.

- Safety Glasses: Shield eyes from debris and liquids.

- Visor: Protects the face from hazardous substances.

- Hard Hat: Guards against falling and flying materials.

- Hearing Protection: Prevents hearing damage.

- Protective Gloves: Shield against mechanical, thermal, and electrical hazards.

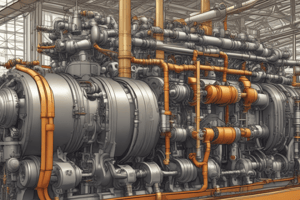

Product Overview: On-Load Tap-Changer

- Used to adjust transformer transmission ratios without interrupting load flow, compensates for voltage fluctuations in power transmission.

- Operated via a motor-drive unit that changes its position based on control impulses.

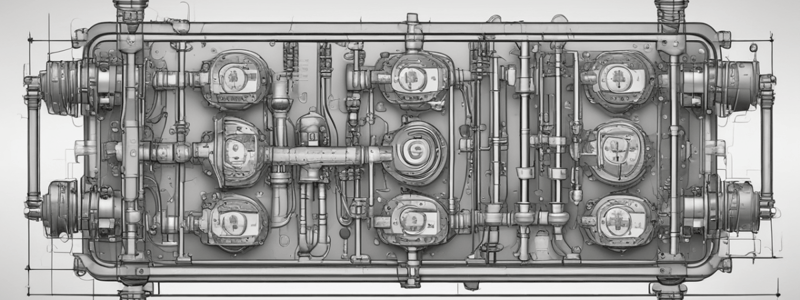

- Key components include the transformer tank, motor-drive unit, drive shafts, and protective relays.

Setup and Models

- On-load tap-changer includes multiple pipe connections, designed for various functions.

- Pipe connections are fitted with bends at the factory and can be manipulated based on requirements.

Protective Devices

- Protective Relay: Monitors flow rate of insulating fluid; triggers circuit breakers in case of faults.

- Pressure Monitoring Device (DW 2000): Prevents excessive pressure increases in the tap-changer; responds to pressure changes and resets manually after activation.

- Rupture Disk: A pressure relief device that responds to overpressure in the oil compartment.

- Tap-Change Supervisory Device: Monitors the operation of the tap-changer's components.

- Temperature Monitoring System: Tracks insulating fluid temperatures.

Drive Shaft

- Connects the motor drive to the on-load tap-changer; utilizes bevel gears to change operational direction.

- Consists of a square tube linked with coupling brackets and bolts.

- Specifications and configurations may require additional support, such as intermediate bearings, for extensive distances between components.### Drive Shaft Configurations

- Drive shaft configurations vary based on the presence of cardan joints and insulators.

- For configurations without intermediate bearings, the length ( V_1 ) must be less than or equal to 2472 mm.

- An intermediate bearing is required when ( V_1 ) exceeds 2472 mm.

- Specific minimum lengths for drive shafts include:

- Without cardan joint and insulator: Minimum 706 mm.

- With cardan joints without an insulator: Minimum ( 798 , \text{mm} ) for ( V_1 > 2564 , \text{mm} ).

- With cardan joints with insulator: Minimum ( 978 , \text{mm} ) for ( V_1 > 2772 , \text{mm} ).

- Maximum permissible axial offsets are:

- 2° for configurations without insulators.

- 20° for configurations with cardan joints.

Commissioning Procedures

- Important safety warning: Ensure no ignition sources are present during commissioning due to the risk of explosion from explosive gases.

- The on-load tap-changer must be filled with approved insulating fluid to prevent damage.

- Procedures for commissioning include:

- Establish pressure equalization before filling the oil compartment.

- Collect and analyze an insulating fluid sample.

- Record sample temperature and assess dielectric strength and water content.

Bleeding Procedures

- Proper bleeding of the on-load tap-changer and suction pipes is crucial for insulation capability.

- Steps for bleeding include:

- Opening all relevant valves and removing air-vent screws to let trapped air escape.

- Ensuring the suction pipe is completely bled to maintain insulation quality.

Motor-Drive Unit Checks

- Ensure that the motor-drive unit is fully submerged in insulating fluid before operation.

- Conduct thorough checks on the coupling and functionality of the motor-drive unit.

- Perform trial tap-change operations across all settings to verify the alignment of indicators.

Protective Relay Testing

- Verify the correct functioning of protective relays before transformer commissioning.

- Procedures include grounding the transformer and testing both passive and active protection measures.

- Ensure the automatic fire extinguishing device is deactivated during testing.

Pressure Monitoring Device Checks

- Confirm sensor functionality on the pressure monitoring device before transformer operation.

- Conduct both passive and active tests to ensure the sensor reacts appropriately to detect pressure anomalies.

Transformer Commissioning Steps

- Ensure all interconnected safety measures and devices are operational prior to energization.

- Execute the start-switch operation after verifying the insulator fluid levels and completeness of oil compartment filling.

Safe Operation of the Motor-Drive Unit

- Manual operation using a hand crank is only permitted under specific circumstances, such as when a transformer is disconnected.

- Clear procedures must be followed when using the hand crank to avoid damage to the on-load tap-changer.

- Emergency operations necessitate strict compliance with safety guidelines due to the risk associated with energized transformers.

Fault Elimination

- Alerts users to danger from explosive gases and the risks associated with tripping protective devices.

- Any instance of protective relay tripping indicates potential damage; the transformer must not be re-energized before a complete inspection.

- Keep protective housing tightly closed to prevent damage from condensation in the motor-drive unit.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz focuses on the operating instructions for the VACUTAP® VM® on-load tap-changer. Participants will learn about the functionality, features, and best practices for using this crucial equipment. Test your knowledge to ensure safe and effective operations.