Podcast

Questions and Answers

What is the manufacturer of the VACUTAP® VM 300?

What is the manufacturer of the VACUTAP® VM 300?

Maschinenfabrik Reinhausen GmbH

Which of the following is considered inappropriate use of the product?

Which of the following is considered inappropriate use of the product?

The VACUTAP® VM 300 is designed for use with an oil filter unit.

The VACUTAP® VM 300 is designed for use with an oil filter unit.

False

What must the serial numbers match for the proper use of the on-load tap-changer?

What must the serial numbers match for the proper use of the on-load tap-changer?

Signup and view all the answers

Which of the following is a signal word indicating a hazardous situation that will result in death or serious injury?

Which of the following is a signal word indicating a hazardous situation that will result in death or serious injury?

Signup and view all the answers

To prevent being caught in rotating parts, one should wear appropriate personal protective ___.

To prevent being caught in rotating parts, one should wear appropriate personal protective ___.

Signup and view all the answers

Match the following signal words with their meanings:

Match the following signal words with their meanings:

Signup and view all the answers

What should you never do when operating the motor-drive unit with the hand crank?

What should you never do when operating the motor-drive unit with the hand crank?

Signup and view all the answers

It is safe to operate the motor-drive unit manually with the hand crank when the transformer is energized.

It is safe to operate the motor-drive unit manually with the hand crank when the transformer is energized.

Signup and view all the answers

What must be done before removing the on-load tap-changer head cover?

What must be done before removing the on-load tap-changer head cover?

Signup and view all the answers

An operation is considered an emergency when a tap-change operation is absolutely necessary while the transformer is _____ despite a fault.

An operation is considered an emergency when a tap-change operation is absolutely necessary while the transformer is _____ despite a fault.

Signup and view all the answers

Match the following fault conditions with their required actions:

Match the following fault conditions with their required actions:

Signup and view all the answers

What should be checked if the on-load tap-changer is not changing tap position?

What should be checked if the on-load tap-changer is not changing tap position?

Signup and view all the answers

The protective relay should remain in the OFF position after tripping.

The protective relay should remain in the OFF position after tripping.

Signup and view all the answers

Which of the following conditions should be ensured for a safe work area?

Which of the following conditions should be ensured for a safe work area?

Signup and view all the answers

The product can be operated in a non-operational condition.

The product can be operated in a non-operational condition.

Signup and view all the answers

What types of conditions must the product's operation comply with?

What types of conditions must the product's operation comply with?

Signup and view all the answers

What should you do with damaged safety markings?

What should you do with damaged safety markings?

Signup and view all the answers

What is the main purpose of on-load tap-changers?

What is the main purpose of on-load tap-changers?

Signup and view all the answers

Unauthorized changes to the product may lead to personal injury, material damage, and operational faults. Only modify the product after consultation with __________.

Unauthorized changes to the product may lead to personal injury, material damage, and operational faults. Only modify the product after consultation with __________.

Signup and view all the answers

Which personal protective equipment is designed to protect against falling heavy objects?

Which personal protective equipment is designed to protect against falling heavy objects?

Signup and view all the answers

What are the requirements for personnel working with the product?

What are the requirements for personnel working with the product?

Signup and view all the answers

What happens when impermissible pressure increases are detected by the pressure monitoring device?

What happens when impermissible pressure increases are detected by the pressure monitoring device?

Signup and view all the answers

Only use __________ materials approved by the manufacturer to avoid malfunctions.

Only use __________ materials approved by the manufacturer to avoid malfunctions.

Signup and view all the answers

Match the following protective equipment with their purpose:

Match the following protective equipment with their purpose:

Signup and view all the answers

What is the function of the rupture disk in an on-load tap-changer?

What is the function of the rupture disk in an on-load tap-changer?

Signup and view all the answers

What is the purpose of the MPREC® pressure relief device?

What is the purpose of the MPREC® pressure relief device?

Signup and view all the answers

What does the tap-change supervisory device monitor?

What does the tap-change supervisory device monitor?

Signup and view all the answers

What is the main function of the drive shaft?

What is the main function of the drive shaft?

Signup and view all the answers

What must be ensured before commissioning the transformer?

What must be ensured before commissioning the transformer?

Signup and view all the answers

The maximum permissible axial offset for the drive shaft is _ degrees.

The maximum permissible axial offset for the drive shaft is _ degrees.

Signup and view all the answers

What must be checked before filling the oil compartment with insulating fluid?

What must be checked before filling the oil compartment with insulating fluid?

Signup and view all the answers

Unsuitable insulating fluids can cause damage to the on-load tap-changer.

Unsuitable insulating fluids can cause damage to the on-load tap-changer.

Signup and view all the answers

What is the procedure for checking the protective relay before commissioning?

What is the procedure for checking the protective relay before commissioning?

Signup and view all the answers

Which of the following is NOT a component of the drive shaft?

Which of the following is NOT a component of the drive shaft?

Signup and view all the answers

What should be done if the pressure monitoring device tripped?

What should be done if the pressure monitoring device tripped?

Signup and view all the answers

What is the first step to take after the pressure monitoring device is tripped?

What is the first step to take after the pressure monitoring device is tripped?

Signup and view all the answers

The on-load tap-changer can be used again immediately after the pressure monitoring device has tripped.

The on-load tap-changer can be used again immediately after the pressure monitoring device has tripped.

Signup and view all the answers

Which of the following actions should be taken if there is leakage from the on-load tap-changer head?

Which of the following actions should be taken if there is leakage from the on-load tap-changer head?

Signup and view all the answers

Ensure that the transformer is not started up under any circumstances when the pressure monitoring device sensor is in the ______.

Ensure that the transformer is not started up under any circumstances when the pressure monitoring device sensor is in the ______.

Signup and view all the answers

What should you do if the sensor is in the OPERATION position?

What should you do if the sensor is in the OPERATION position?

Signup and view all the answers

What should you monitor annually on the motor-drive unit/control cabinet?

What should you monitor annually on the motor-drive unit/control cabinet?

Signup and view all the answers

Regular visual checks are sufficient for monitoring the on-load tap-changer.

Regular visual checks are sufficient for monitoring the on-load tap-changer.

Signup and view all the answers

After every ______ switching operations, maintenance of the on-load tap-changer is necessary.

After every ______ switching operations, maintenance of the on-load tap-changer is necessary.

Signup and view all the answers

If the MR monitoring system fails, what should you do?

If the MR monitoring system fails, what should you do?

Signup and view all the answers

What must be ensured when filling the oil compartment with fresh insulating fluid?

What must be ensured when filling the oil compartment with fresh insulating fluid?

Signup and view all the answers

What is the purpose of the VACUTAP® VM 300?

What is the purpose of the VACUTAP® VM 300?

Signup and view all the answers

The product can be used with an oil filter unit.

The product can be used with an oil filter unit.

Signup and view all the answers

Which of the following are considered appropriate uses of the VACUTAP® VM 300? (Select all that apply)

Which of the following are considered appropriate uses of the VACUTAP® VM 300? (Select all that apply)

Signup and view all the answers

The warnings in this technical file are designed to prevent injuries related to __________.

The warnings in this technical file are designed to prevent injuries related to __________.

Signup and view all the answers

What should be done to ensure safe operation and maintenance of the product?

What should be done to ensure safe operation and maintenance of the product?

Signup and view all the answers

All operating conditions outside of the design data are permitted as long as measures are taken.

All operating conditions outside of the design data are permitted as long as measures are taken.

Signup and view all the answers

What is a rupture disk?

What is a rupture disk?

Signup and view all the answers

What does the MPREC® pressure relief device do?

What does the MPREC® pressure relief device do?

Signup and view all the answers

What does the tap-change supervisory device monitor?

What does the tap-change supervisory device monitor?

Signup and view all the answers

Which of the following components are part of the drive shaft?

Which of the following components are part of the drive shaft?

Signup and view all the answers

The on-load tap-changer requires a pressure relief device if it has a flange for attaching a __________.

The on-load tap-changer requires a pressure relief device if it has a flange for attaching a __________.

Signup and view all the answers

The drive shaft can be operational without insulating fluid.

The drive shaft can be operational without insulating fluid.

Signup and view all the answers

Match the following drive shaft configurations with their minimum length requirements:

Match the following drive shaft configurations with their minimum length requirements:

Signup and view all the answers

What must be checked to ensure proper commissioning of the transformer?

What must be checked to ensure proper commissioning of the transformer?

Signup and view all the answers

When should the intermediate bearing be used?

When should the intermediate bearing be used?

Signup and view all the answers

Untidy and poorly lit work areas can lead to accidents.

Untidy and poorly lit work areas can lead to accidents.

Signup and view all the answers

What must be checked regularly to ensure the operational reliability of safety equipment?

What must be checked regularly to ensure the operational reliability of safety equipment?

Signup and view all the answers

What should be avoided when operating the product?

What should be avoided when operating the product?

Signup and view all the answers

Only use ___________ approved by the manufacturer.

Only use ___________ approved by the manufacturer.

Signup and view all the answers

What type of personnel is responsible for assembly and operation?

What type of personnel is responsible for assembly and operation?

Signup and view all the answers

The electrically skilled person is not required to meet applicable statutory regulations for accident prevention.

The electrically skilled person is not required to meet applicable statutory regulations for accident prevention.

Signup and view all the answers

Which of the following is personal protective equipment?

Which of the following is personal protective equipment?

Signup and view all the answers

What is the main function of the on-load tap-changer?

What is the main function of the on-load tap-changer?

Signup and view all the answers

What should be the condition of personal protective equipment before use?

What should be the condition of personal protective equipment before use?

Signup and view all the answers

What does the protective relay do?

What does the protective relay do?

Signup and view all the answers

Match the personnel roles with their descriptions:

Match the personnel roles with their descriptions:

Signup and view all the answers

Inrush current impulses can lead to overload the on-load tap-changer.

Inrush current impulses can lead to overload the on-load tap-changer.

Signup and view all the answers

When should you perform tap-change operations under load conditions?

When should you perform tap-change operations under load conditions?

Signup and view all the answers

What should you do if the hand crank is difficult to move?

What should you do if the hand crank is difficult to move?

Signup and view all the answers

Who should you contact if there is doubt about the on-load tap-changer?

Who should you contact if there is doubt about the on-load tap-changer?

Signup and view all the answers

An operation is considered an emergency operation if a tap-change operation is absolutely necessary when a transformer is _____ .

An operation is considered an emergency operation if a tap-change operation is absolutely necessary when a transformer is _____ .

Signup and view all the answers

What may cause tripping of the protective relay?

What may cause tripping of the protective relay?

Signup and view all the answers

It is safe to operate the motor-drive unit electrically while the transformer is connected if a fault is suspected.

It is safe to operate the motor-drive unit electrically while the transformer is connected if a fault is suspected.

Signup and view all the answers

What should be done if insulating fluid is leaking from the transformer?

What should be done if insulating fluid is leaking from the transformer?

Signup and view all the answers

What should you do if the pressure monitoring device has been tripped?

What should you do if the pressure monitoring device has been tripped?

Signup and view all the answers

You can re-commission the transformer without determining the cause for tripping the pressure monitoring device.

You can re-commission the transformer without determining the cause for tripping the pressure monitoring device.

Signup and view all the answers

How often should you check the quality of the insulating fluid for on-load tap-changers installed in positions other than the neutral point of windings?

How often should you check the quality of the insulating fluid for on-load tap-changers installed in positions other than the neutral point of windings?

Signup and view all the answers

The stop-cock between the oil conservator and the on-load tap-changer should be ______ before emptying the oil compartment.

The stop-cock between the oil conservator and the on-load tap-changer should be ______ before emptying the oil compartment.

Signup and view all the answers

What is a significant danger when working on an energized transformer?

What is a significant danger when working on an energized transformer?

Signup and view all the answers

You can operate electrical devices near a transformer if there are no apparent ignition sources.

You can operate electrical devices near a transformer if there are no apparent ignition sources.

Signup and view all the answers

What should you do if insulating fluid is leaking?

What should you do if insulating fluid is leaking?

Signup and view all the answers

What is the required action upon receiving a maintenance warning from the MR monitoring system?

What is the required action upon receiving a maintenance warning from the MR monitoring system?

Signup and view all the answers

The insulating fluid must comply with the limit values specified in the ______.

The insulating fluid must comply with the limit values specified in the ______.

Signup and view all the answers

Match the following intervals with the corresponding action:

Match the following intervals with the corresponding action:

Signup and view all the answers

What does the product on-load tap-changer adjust?

What does the product on-load tap-changer adjust?

Signup and view all the answers

Which of the following pertains to inappropriate use of the on-load tap-changer? (Select all that apply)

Which of the following pertains to inappropriate use of the on-load tap-changer? (Select all that apply)

Signup and view all the answers

The on-load tap-changer can be used with an oil filter unit.

The on-load tap-changer can be used with an oil filter unit.

Signup and view all the answers

Which personal protective equipment should be worn during operation? (Select all that apply)

Which personal protective equipment should be worn during operation? (Select all that apply)

Signup and view all the answers

The appropriate use of the on-load tap-changer is limited to __________.

The appropriate use of the on-load tap-changer is limited to __________.

Signup and view all the answers

What should be done if personal protective equipment is damaged?

What should be done if personal protective equipment is damaged?

Signup and view all the answers

Inrush current impulses can lead to overload of the on-load tap-changer during diverter switch operation.

Inrush current impulses can lead to overload of the on-load tap-changer during diverter switch operation.

Signup and view all the answers

When should tap-change operations be performed?

When should tap-change operations be performed?

Signup and view all the answers

It is safe to operate the motor-drive unit with the hand crank if a fault is suspected in the transformer.

It is safe to operate the motor-drive unit with the hand crank if a fault is suspected in the transformer.

Signup and view all the answers

What should you do if the hand crank is difficult to move?

What should you do if the hand crank is difficult to move?

Signup and view all the answers

What is one reason for carrying out a tap-change operation with the hand crank?

What is one reason for carrying out a tap-change operation with the hand crank?

Signup and view all the answers

A tap-change operation is considered an emergency when it is absolutely necessary while the transformer is __________.

A tap-change operation is considered an emergency when it is absolutely necessary while the transformer is __________.

Signup and view all the answers

What should be done if a protective relay or other protective devices trip?

What should be done if a protective relay or other protective devices trip?

Signup and view all the answers

What type of device must be de-energized before removing the on-load tap-changer head cover?

What type of device must be de-energized before removing the on-load tap-changer head cover?

Signup and view all the answers

What should be done if insulating fluid is leaking from the on-load tap-changer head cover?

What should be done if insulating fluid is leaking from the on-load tap-changer head cover?

Signup and view all the answers

What should you do if the flap valve of the protective relay is in the OFF position?

What should you do if the flap valve of the protective relay is in the OFF position?

Signup and view all the answers

Untidy and poorly lit work areas can lead to accidents.

Untidy and poorly lit work areas can lead to accidents.

Signup and view all the answers

What should not be done in areas where a risk of explosion is present?

What should not be done in areas where a risk of explosion is present?

Signup and view all the answers

What is the role of warning signs and safety information plates on the product?

What is the role of warning signs and safety information plates on the product?

Signup and view all the answers

Who is responsible for ensuring personnel are sufficiently qualified?

Who is responsible for ensuring personnel are sufficiently qualified?

Signup and view all the answers

Personal protective equipment must be worn during work to minimize risks to health. Always wear the personal protective equipment required for the job ___ hand.

Personal protective equipment must be worn during work to minimize risks to health. Always wear the personal protective equipment required for the job ___ hand.

Signup and view all the answers

Match the following types of personnel with their qualifications:

Match the following types of personnel with their qualifications:

Signup and view all the answers

What type of clothing should be worn to protect against getting caught by moving machine parts?

What type of clothing should be worn to protect against getting caught by moving machine parts?

Signup and view all the answers

What is the function of the protective relay in an on-load tap-changer?

What is the function of the protective relay in an on-load tap-changer?

Signup and view all the answers

The on-load tap-changer is used to adjust the transmission ratio of transformers without interrupting the ___ flow.

The on-load tap-changer is used to adjust the transmission ratio of transformers without interrupting the ___ flow.

Signup and view all the answers

What happens if maintenance is not carried out by the Technical Service department?

What happens if maintenance is not carried out by the Technical Service department?

Signup and view all the answers

What should you do if the pressure monitoring device trips the circuit breaker?

What should you do if the pressure monitoring device trips the circuit breaker?

Signup and view all the answers

If the pressure monitoring device sensor is in the OFF position, which of the following should you NOT do?

If the pressure monitoring device sensor is in the OFF position, which of the following should you NOT do?

Signup and view all the answers

One should operate electrical devices near the transformer to check for any ignition sources.

One should operate electrical devices near the transformer to check for any ignition sources.

Signup and view all the answers

If the dielectric strength and water content do not comply with the limit values, change the insulating fluid in accordance with the '__________' section.

If the dielectric strength and water content do not comply with the limit values, change the insulating fluid in accordance with the '__________' section.

Signup and view all the answers

When can the transformer be re-commissioned?

When can the transformer be re-commissioned?

Signup and view all the answers

How often should the quality of the insulating fluid be checked for on-load tap-changers installed in positions other than the neutral point of windings?

How often should the quality of the insulating fluid be checked for on-load tap-changers installed in positions other than the neutral point of windings?

Signup and view all the answers

Match the frequency of maintenance actions to their corresponding actions:

Match the frequency of maintenance actions to their corresponding actions:

Signup and view all the answers

There is no danger of explosion when working in the oil compartment of the on-load tap-changer.

There is no danger of explosion when working in the oil compartment of the on-load tap-changer.

Signup and view all the answers

What should be done if the motor-drive unit has been operated without being properly coupled?

What should be done if the motor-drive unit has been operated without being properly coupled?

Signup and view all the answers

What is the function of the rupture disk in the on-load tap-changer?

What is the function of the rupture disk in the on-load tap-changer?

Signup and view all the answers

What does the MPREC® pressure relief device respond to?

What does the MPREC® pressure relief device respond to?

Signup and view all the answers

The temperature monitoring system checks the temperature of the air outside the on-load tap-changer.

The temperature monitoring system checks the temperature of the air outside the on-load tap-changer.

Signup and view all the answers

What does the drive shaft connect?

What does the drive shaft connect?

Signup and view all the answers

Which part of the drive shaft changes the direction of motion?

Which part of the drive shaft changes the direction of motion?

Signup and view all the answers

The drive shaft with cardan joints can handle a maximum permissible axial offset of _____ degrees.

The drive shaft with cardan joints can handle a maximum permissible axial offset of _____ degrees.

Signup and view all the answers

It is acceptable to operate the on-load tap-changer without a pressure relief device if it has a flange.

It is acceptable to operate the on-load tap-changer without a pressure relief device if it has a flange.

Signup and view all the answers

What must be checked during commissioning regarding insulating fluids?

What must be checked during commissioning regarding insulating fluids?

Signup and view all the answers

What activates the sensor on the snap-action switch during the pressure monitoring device check?

What activates the sensor on the snap-action switch during the pressure monitoring device check?

Signup and view all the answers

During commissioning, the oil compartment of the on-load tap-changer must be completely filled with _____ fluid.

During commissioning, the oil compartment of the on-load tap-changer must be completely filled with _____ fluid.

Signup and view all the answers

Which of these practices should be followed to maintain a safe work area? (Select all that apply)

Which of these practices should be followed to maintain a safe work area? (Select all that apply)

Signup and view all the answers

The product may be operated in any condition regardless of its operational reliability.

The product may be operated in any condition regardless of its operational reliability.

Signup and view all the answers

What should you do if safety markings are damaged or missing?

What should you do if safety markings are damaged or missing?

Signup and view all the answers

Auxiliary materials not approved by the manufacturer can lead to personal injury and _____.

Auxiliary materials not approved by the manufacturer can lead to personal injury and _____.

Signup and view all the answers

Who should modifications to the product be discussed with?

Who should modifications to the product be discussed with?

Signup and view all the answers

Which types of personnel are mentioned in the document? (Select all that apply)

Which types of personnel are mentioned in the document? (Select all that apply)

Signup and view all the answers

Personal protective equipment is optional during work.

Personal protective equipment is optional during work.

Signup and view all the answers

What type of clothing should be worn in the workplace?

What type of clothing should be worn in the workplace?

Signup and view all the answers

Match the following personal protective equipment with their purpose:

Match the following personal protective equipment with their purpose:

Signup and view all the answers

Where is the nameplate with the serial number located on the on-load tap-changer?

Where is the nameplate with the serial number located on the on-load tap-changer?

Signup and view all the answers

The protective relay responds to gas accumulation.

The protective relay responds to gas accumulation.

Signup and view all the answers

What must the sensor on the pressure monitoring device be reset by?

What must the sensor on the pressure monitoring device be reset by?

Signup and view all the answers

What is the function of a rupture disk?

What is the function of a rupture disk?

Signup and view all the answers

What does the pressure relief device MPREC® respond to?

What does the pressure relief device MPREC® respond to?

Signup and view all the answers

What does the temperature monitoring system do?

What does the temperature monitoring system do?

Signup and view all the answers

What is the role of the drive shaft in the on-load tap-changer?

What is the role of the drive shaft in the on-load tap-changer?

Signup and view all the answers

The drive shaft can only be used in vertical configurations.

The drive shaft can only be used in vertical configurations.

Signup and view all the answers

The configuration for the drive shaft with cardan joints, without insulator is __________.

The configuration for the drive shaft with cardan joints, without insulator is __________.

Signup and view all the answers

What must be checked during commissioning of the transformer?

What must be checked during commissioning of the transformer?

Signup and view all the answers

What happens if the on-load tap-changer is overloaded?

What happens if the on-load tap-changer is overloaded?

Signup and view all the answers

What must be done to avoid dangers related to explosive gases during commissioning?

What must be done to avoid dangers related to explosive gases during commissioning?

Signup and view all the answers

During the commissioning process, which value must comply with technical data limits?

During the commissioning process, which value must comply with technical data limits?

Signup and view all the answers

When the maximum value of V1 is exceeded, it is necessary to use an __________.

When the maximum value of V1 is exceeded, it is necessary to use an __________.

Signup and view all the answers

The signaling contact for the minimum insulating fluid fill level is not linked to the circuit breaker.

The signaling contact for the minimum insulating fluid fill level is not linked to the circuit breaker.

Signup and view all the answers

Who is the manufacturer of the VACUTAP® VM 300?

Who is the manufacturer of the VACUTAP® VM 300?

Signup and view all the answers

What is the main function of the on-load tap-changer?

What is the main function of the on-load tap-changer?

Signup and view all the answers

The on-load tap-changer is intended for use only with the specified transformer/motor-drive unit.

The on-load tap-changer is intended for use only with the specified transformer/motor-drive unit.

Signup and view all the answers

What should you check after the pressure monitoring device has been tripped?

What should you check after the pressure monitoring device has been tripped?

Signup and view all the answers

Which of the following is considered appropriate use for the on-load tap-changer? (Select all that apply)

Which of the following is considered appropriate use for the on-load tap-changer? (Select all that apply)

Signup and view all the answers

This technical file is intended solely for __________ trained and authorized personnel.

This technical file is intended solely for __________ trained and authorized personnel.

Signup and view all the answers

If the sensor is in the ______ position, there may be an error in the tripping circuit.

If the sensor is in the ______ position, there may be an error in the tripping circuit.

Signup and view all the answers

What should personal protective equipment include when operating the product?

What should personal protective equipment include when operating the product?

Signup and view all the answers

What actions should you take if the pressure monitoring device tripped? (Select all that apply)

What actions should you take if the pressure monitoring device tripped? (Select all that apply)

Signup and view all the answers

The insulating fluid needs to be changed if the dielectric strength and water content do not comply with limit values.

The insulating fluid needs to be changed if the dielectric strength and water content do not comply with limit values.

Signup and view all the answers

Wearing jewelry is recommended while using the on-load tap-changer.

Wearing jewelry is recommended while using the on-load tap-changer.

Signup and view all the answers

What must you ensure before re-commissioning the transformer?

What must you ensure before re-commissioning the transformer?

Signup and view all the answers

What happens if the operating conditions exceed the permitted limits?

What happens if the operating conditions exceed the permitted limits?

Signup and view all the answers

Match the following inspection intervals with their associated actions:

Match the following inspection intervals with their associated actions:

Signup and view all the answers

Warnings in the technical file are displayed in a __________ format.

Warnings in the technical file are displayed in a __________ format.

Signup and view all the answers

What should be done if the insulating fluid does not comply with limit values? (Select all that apply)

What should be done if the insulating fluid does not comply with limit values? (Select all that apply)

Signup and view all the answers

What should be visible connected to ground before working on the transformer?

What should be visible connected to ground before working on the transformer?

Signup and view all the answers

What can inrush current impulses lead to during the diverter switch operation?

What can inrush current impulses lead to during the diverter switch operation?

Signup and view all the answers

It is safe to operate the motor-drive unit electrically or with the hand crank before disconnecting the transformer if faulty.

It is safe to operate the motor-drive unit electrically or with the hand crank before disconnecting the transformer if faulty.

Signup and view all the answers

Always keep protective housing of the motor-drive unit tightly ______.

Always keep protective housing of the motor-drive unit tightly ______.

Signup and view all the answers

During which operation is it permitted to use the hand crank?

During which operation is it permitted to use the hand crank?

Signup and view all the answers

What should be done when tripping of protective relay occurs?

What should be done when tripping of protective relay occurs?

Signup and view all the answers

What should you do if insulating fluid is leaking?

What should you do if insulating fluid is leaking?

Signup and view all the answers

You should wait 15 minutes after switching off the transformer before working on the protective relay.

You should wait 15 minutes after switching off the transformer before working on the protective relay.

Signup and view all the answers

What action should be taken if the on-load tap-changer is not changing tap position?

What action should be taken if the on-load tap-changer is not changing tap position?

Signup and view all the answers

What type of operation is considered an emergency operation?

What type of operation is considered an emergency operation?

Signup and view all the answers

What is the purpose of the on-load tap-changer?

What is the purpose of the on-load tap-changer?

Signup and view all the answers

The product is intended for use outside electrical energy systems.

The product is intended for use outside electrical energy systems.

Signup and view all the answers

Which of the following actions is considered appropriate use of the product? (Select all that apply)

Which of the following actions is considered appropriate use of the product? (Select all that apply)

Signup and view all the answers

The product must not be used with an ______ filter unit.

The product must not be used with an ______ filter unit.

Signup and view all the answers

What must match if the on-load tap-changer and accessories are supplied as a set for one order?

What must match if the on-load tap-changer and accessories are supplied as a set for one order?

Signup and view all the answers

It is safe to wear jewelry while operating the product.

It is safe to wear jewelry while operating the product.

Signup and view all the answers

Which signal word indicates a hazardous situation that could result in minor or moderate injury?

Which signal word indicates a hazardous situation that could result in minor or moderate injury?

Signup and view all the answers

The manufacturer of the product is Maschinenfabrik ______ GmbH.

The manufacturer of the product is Maschinenfabrik ______ GmbH.

Signup and view all the answers

Inrush current impulses can be less than the transformer rated current.

Inrush current impulses can be less than the transformer rated current.

Signup and view all the answers

What should be ensured before performing tap-change operations?

What should be ensured before performing tap-change operations?

Signup and view all the answers

It is safe to operate the motor-drive unit with the hand crank before disconnecting the transformer if a fault is suspected.

It is safe to operate the motor-drive unit with the hand crank before disconnecting the transformer if a fault is suspected.

Signup and view all the answers

What is a crucial step before using the hand crank during tap-change operation?

What is a crucial step before using the hand crank during tap-change operation?

Signup and view all the answers

What must be done if the hand crank is difficult to move?

What must be done if the hand crank is difficult to move?

Signup and view all the answers

An operation is considered an emergency operation if a tap-change operation is absolutely necessary when a transformer is ______.

An operation is considered an emergency operation if a tap-change operation is absolutely necessary when a transformer is ______.

Signup and view all the answers

What should be checked if the protective relay trips?

What should be checked if the protective relay trips?

Signup and view all the answers

The transformer can be energized without being inspected first if the protective relay has tripped.

The transformer can be energized without being inspected first if the protective relay has tripped.

Signup and view all the answers

What is the maximum allowable time to wait after switching off the transformer before working on the protective relay?

What is the maximum allowable time to wait after switching off the transformer before working on the protective relay?

Signup and view all the answers

Always keep the protective housing of the motor-drive unit tightly ______.

Always keep the protective housing of the motor-drive unit tightly ______.

Signup and view all the answers

What is a rupture disk?

What is a rupture disk?

Signup and view all the answers

What does the tap-change supervisory device monitor?

What does the tap-change supervisory device monitor?

Signup and view all the answers

What is the maximum permissible axial offset for the drive shaft configuration?

What is the maximum permissible axial offset for the drive shaft configuration?

Signup and view all the answers

The drive shaft is a mechanical connection between the drive and the de-energized tap-changer.

The drive shaft is a mechanical connection between the drive and the de-energized tap-changer.

Signup and view all the answers

What must be used to prevent damage to the on-load tap-changer?

What must be used to prevent damage to the on-load tap-changer?

Signup and view all the answers

What action should be taken if the on-load tap-changer head cover has a flange for attaching a pressure relief device?

What action should be taken if the on-load tap-changer head cover has a flange for attaching a pressure relief device?

Signup and view all the answers

What should be checked before commissioning the transformer?

What should be checked before commissioning the transformer?

Signup and view all the answers

Which of the following is a feature of the pressure relief device MPREC®?

Which of the following is a feature of the pressure relief device MPREC®?

Signup and view all the answers

The drive shaft without cardan joint and without insulator is the _______ version.

The drive shaft without cardan joint and without insulator is the _______ version.

Signup and view all the answers

During the commissioning process, what should be done with the automatic fire extinguishing device?

During the commissioning process, what should be done with the automatic fire extinguishing device?

Signup and view all the answers

The insulating fluid level should fall below the minimum threshold before commissioning.

The insulating fluid level should fall below the minimum threshold before commissioning.

Signup and view all the answers

What can untidy and poorly lit work areas lead to?

What can untidy and poorly lit work areas lead to?

Signup and view all the answers

The product may only be operated in a sound, operational condition.

The product may only be operated in a sound, operational condition.

Signup and view all the answers

What must be observed to ensure safety during operation?

What must be observed to ensure safety during operation?

Signup and view all the answers

What should be avoided in areas where a risk of explosion is present?

What should be avoided in areas where a risk of explosion is present?

Signup and view all the answers

Only use insulating fluids _____ by the manufacturer.

Only use insulating fluids _____ by the manufacturer.

Signup and view all the answers

Who should modifications to the product be consulted with?

Who should modifications to the product be consulted with?

Signup and view all the answers

What is the role of an electrically skilled person?

What is the role of an electrically skilled person?

Signup and view all the answers

What must personal protective equipment be during work?

What must personal protective equipment be during work?

Signup and view all the answers

Always wear damaged personal protective equipment.

Always wear damaged personal protective equipment.

Signup and view all the answers

What is the purpose of safety shoes?

What is the purpose of safety shoes?

Signup and view all the answers

Match the following protective equipment with their main purpose:

Match the following protective equipment with their main purpose:

Signup and view all the answers

What is the function of the protective relay in the on-load tap-changer?

What is the function of the protective relay in the on-load tap-changer?

Signup and view all the answers

The pressure monitoring device does not respond to gas accumulation.

The pressure monitoring device does not respond to gas accumulation.

Signup and view all the answers

What are the two variants of the pressure monitoring device?

What are the two variants of the pressure monitoring device?

Signup and view all the answers

What should you do after the pressure monitoring device has been tripped?

What should you do after the pressure monitoring device has been tripped?

Signup and view all the answers

What is the first step to take if the circuit breaker is tripped by the pressure monitoring device?

What is the first step to take if the circuit breaker is tripped by the pressure monitoring device?

Signup and view all the answers

The motor drive unit should be actuated by remote control after the pressure monitoring device has tripped.

The motor drive unit should be actuated by remote control after the pressure monitoring device has tripped.

Signup and view all the answers

What is one precaution to take if the sensor is in the OPERATION position?

What is one precaution to take if the sensor is in the OPERATION position?

Signup and view all the answers

If the sensor is in the OFF position, what is the first action to take?

If the sensor is in the OFF position, what is the first action to take?

Signup and view all the answers

What can result in serious injury when working on the on-load tap-changer?

What can result in serious injury when working on the on-load tap-changer?

Signup and view all the answers

How often should the quality of the insulating fluid be checked for on-load tap-changers installed in positions other than the neutral point?

How often should the quality of the insulating fluid be checked for on-load tap-changers installed in positions other than the neutral point?

Signup and view all the answers

The interval for maintenance of the on-load tap-changer after every __________ switching operations is mandatory.

The interval for maintenance of the on-load tap-changer after every __________ switching operations is mandatory.

Signup and view all the answers

It is safe to operate the motor-drive unit when the horizontal drive shaft has been removed.

It is safe to operate the motor-drive unit when the horizontal drive shaft has been removed.

Signup and view all the answers

What must be checked before filling the oil compartment with fresh insulating fluid?

What must be checked before filling the oil compartment with fresh insulating fluid?

Signup and view all the answers

Study Notes

Introduction

- Operating instructions cover operation, fault management, and maintenance of the VACUTAP® VM 300 on-load tap-changer.

- Manufacturer: Maschinenfabrik Reinhausen GmbH, based in Regensburg, Germany.

- Important to retain related documents such as unpacking instructions, routine test reports, and order confirmations for completeness.

- Technical communication includes hazard warnings and detailed instructions to ensure safety in operation.

Safety

- Emphasizes the importance of familiarizing oneself with the product and safety instructions to avoid function-related dangers.

- Appropriate use is limited to electrical energy systems; must match specifications in official technical documents.

- On-load tap-changer operates without interrupting load flow, suitable only for designated transformers.

- Inappropriate use, including operating under non-compliant electrical conditions, poses risks to safety and can damage the product.

Personal Protective Equipment

- Use of personal protective equipment (PPE) is mandatory to avoid accidents, including helmets and gloves.

- Loose clothing and jewelry should not be worn to prevent entanglement; hair should be secured.

Operational Guidelines

- Regular checks of operational reliability and maintenance as per guidelines ensure continued safety and functionality.

- Ensure well-lit and organized work environments to prevent accidents.

- Do not perform operations in areas with explosion risks; adhere to explosion protection measures.

Hazard Communication

- Warning labels indicate potential dangers and required precautions; maintaining visibility and legibility is crucial.

- Different signal words indicate levels of risk: DANGER (life-threatening), WARNING (serious injury), CAUTION (minor injury), and NOTICE (property damage).

Ambient and Operational Conditions

- Must operate within specified ambient conditions for reliable functionality.

- Use only approved insulating fluids, lubricants, and operating materials to prevent malfunctions and enhance safety.

Maintenance and Inspection

- Scheduled inspections and maintenance activities as indicated in the technical file are critical for safe operation.

- Proper maintenance practices can mitigate risks associated with wear and tear of components.

Documentation and Communication

- Retain access to all technical and supporting documents for reference, enhancing understanding and effective operational practices.

- Communication of important details is structured clearly for better comprehension and adherence to procedures.### Modifications and Conversions

- Unauthorized modifications can lead to personal injuries, material damage, or operational faults.

- Consult Maschinenfabrik Reinhausen GmbH before making any changes.

Spare Parts

- Using unapproved spare parts can cause physical injury and malfunctions.

- Only utilize spare parts that are authorized by Maschinenfabrik Reinhausen GmbH.

Personnel Qualification

- Assembly and maintenance responsibilities require qualified personnel.

Electrically Skilled Person

- Must have technical qualifications, knowledge of standards, and safety regulations.

- Capable of identifying and avoiding potential dangers and can perform work on electrical systems.

Electrically Trained Persons

- Receive guidance from electrically skilled personnel regarding tasks and potential dangers.

Operator Responsibilities

- Operate the product according to the technical file and receive training on specific tasks and dangers.

Technical Service

- Maintenance and repairs should ideally be performed by the Technical Service department of Maschinenfabrik Reinhausen GmbH.

Authorized Personnel

- Specifically trained by the company for special maintenance tasks.

Personal Protective Equipment (PPE)

- Always wear the required PPE to minimize health risks.

- Avoid using damaged PPE.

- Types of PPE include:

- Protective Clothing: Close-fitting to prevent entanglement.

- Safety Shoes: Protect against heavy objects and slipping.

- Safety Glasses: Shield eyes from debris and liquids.

- Visor: Additional facial protection from splashes and debris.

- Hard Hat: Protects against falling objects.

- Hearing Protection: Safeguards against noise damage.

- Protective Gloves: Defend against thermal, mechanical, and electrical hazards.

Product Description of On-Load Tap-Changer

- Used to adjust transformer transmission ratios without interrupting load flow.

- Functions by responding to control impulses to adapt to operating conditions.

Setup/Versions

- Main components include:

- Transformer tank, motor-drive unit, vertical and horizontal drive shafts, on-load tap-changer, oil conservator, and protective relays.

Pipe Connections

- Multiple pipe connections serve functions such as draining and pressure equalization.

- Pipe Connection Q: Closed with a cover; used for supervisory device connections.

- Pipe Connection S: Draining function with a vent screw.

- Pipe Connection R: Connects protective relay and conservator.

- Pipe Connection E2: Used for pressure equalization and Buchholz relay connection.

Protective Devices

- Protective Relay: Trips when excessive flow is detected; essential for safety and de-energizing transformers.

- Pressure Monitoring Device (DW): Protects against excessive pressure with quick response.

- Rupture Disk: A pressure relief device responding to overpressure situations.

- Tap-Change Supervisory Device: Monitors drive shafts and the switching of the diverter switch.

- Temperature Monitoring: Ensures safe temperature levels of the insulating oil.

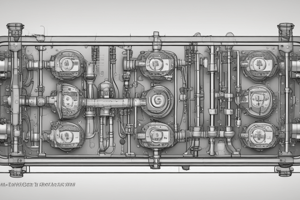

Drive Shaft Function

- Mechanically connects the drive and on-load tap-changer; utilizes bevel gears to redirect motion.

Design/Versions

- Made up of a square tube, coupling brackets, and bolts for secure connections.

- If the maximum axial offset exceeds 2472 mm, an intermediate bearing is necessary for stability.### Drive Shaft Configurations

- Drive shafts can either have a cardan joint or an insulator.

- Maximum permissible axial offset for various configurations ranges from 2° to 20°.

- Drive shafts without an intermediate bearing are for lengths (V1) less than or equal to 2472 mm.

- Use of intermediate bearings is mandatory for lengths exceeding specified limits:

- V1 > 2472 mm requires intermediate bearing for shafts without insulator.

- V1 > 2564 mm for drive shafts with cardan joints without insulator.

- V1 > 2772 mm for drive shafts with cardan joints with insulator.

Commissioning Process

- Ensure no ignition sources are present in the vicinity to prevent explosions.

- Only use approved insulating fluids to avoid damage to the tap-changer.

- Check for proper flange attachment for pressure relief device; operation without it is not permitted.

- Establish equal pressure in oil compartments before starting evacuation process.

- Fill the on-load tap-changer with new insulating fluid at designated pipe connections.

Bleeding Procedures

- Open all valves before bleeding air from the on-load tap-changer and suction pipe.

- Ensuring complete bleeding of the suction pipe is essential for insulation capability.

- Seal all openings securely after bleeding to maintain system integrity.

Motor-Drive Unit Checks

- Ensure the on-load tap-changer is immersed in insulating fluid before activation.

- Function checks must be performed according to manufacturer's operating instructions.

- Motor-drive unit coupling must be accurately inspected to prevent damage.

Protective Relay Testing

- Conduct tests before transformer commissioning to confirm protective relay functionality.

- Ensure grounding during tests and that the transformer remains de-energized.

- Conduct passive and active protection tests by simulating operational conditions.

Pressure Monitoring Device Examination

- Ground the transformer and ensure de-energization during testing.

- Follow active and passive protection tests for the pressure monitoring device prior to commissioning.

Handling Emergencies

- Operation of the motor-drive unit with a hand crank should only occur under strict conditions.

- Unauthorized operation may result in severe injury or death.

- Avoid completion of tap-change operations electrically if initiated manually.

- If the hand crank is difficult to operate, stop immediately to prevent damage.

Fault Elimination Procedures

- Removal of the on-load tap-changer head cover must be done carefully to avoid explosions.

- De-energize all circuits prior to maintenance work to ensure safety.

- Inspect on-load tap-changer and transformer immediately if protective relays trip to prevent further damage.

Introduction

- Operating instructions cover operation, fault management, and maintenance of the VACUTAP® VM 300 on-load tap-changer.

- Manufacturer: Maschinenfabrik Reinhausen GmbH, based in Regensburg, Germany.

- Important to retain related documents such as unpacking instructions, routine test reports, and order confirmations for completeness.

- Technical communication includes hazard warnings and detailed instructions to ensure safety in operation.

Safety

- Emphasizes the importance of familiarizing oneself with the product and safety instructions to avoid function-related dangers.

- Appropriate use is limited to electrical energy systems; must match specifications in official technical documents.

- On-load tap-changer operates without interrupting load flow, suitable only for designated transformers.

- Inappropriate use, including operating under non-compliant electrical conditions, poses risks to safety and can damage the product.

Personal Protective Equipment

- Use of personal protective equipment (PPE) is mandatory to avoid accidents, including helmets and gloves.

- Loose clothing and jewelry should not be worn to prevent entanglement; hair should be secured.

Operational Guidelines

- Regular checks of operational reliability and maintenance as per guidelines ensure continued safety and functionality.

- Ensure well-lit and organized work environments to prevent accidents.

- Do not perform operations in areas with explosion risks; adhere to explosion protection measures.

Hazard Communication

- Warning labels indicate potential dangers and required precautions; maintaining visibility and legibility is crucial.

- Different signal words indicate levels of risk: DANGER (life-threatening), WARNING (serious injury), CAUTION (minor injury), and NOTICE (property damage).

Ambient and Operational Conditions

- Must operate within specified ambient conditions for reliable functionality.

- Use only approved insulating fluids, lubricants, and operating materials to prevent malfunctions and enhance safety.

Maintenance and Inspection

- Scheduled inspections and maintenance activities as indicated in the technical file are critical for safe operation.

- Proper maintenance practices can mitigate risks associated with wear and tear of components.

Documentation and Communication

- Retain access to all technical and supporting documents for reference, enhancing understanding and effective operational practices.

- Communication of important details is structured clearly for better comprehension and adherence to procedures.### Modifications and Conversions

- Unauthorized modifications can lead to personal injuries, material damage, or operational faults.

- Consult Maschinenfabrik Reinhausen GmbH before making any changes.

Spare Parts

- Using unapproved spare parts can cause physical injury and malfunctions.

- Only utilize spare parts that are authorized by Maschinenfabrik Reinhausen GmbH.

Personnel Qualification

- Assembly and maintenance responsibilities require qualified personnel.

Electrically Skilled Person

- Must have technical qualifications, knowledge of standards, and safety regulations.

- Capable of identifying and avoiding potential dangers and can perform work on electrical systems.

Electrically Trained Persons

- Receive guidance from electrically skilled personnel regarding tasks and potential dangers.

Operator Responsibilities

- Operate the product according to the technical file and receive training on specific tasks and dangers.

Technical Service

- Maintenance and repairs should ideally be performed by the Technical Service department of Maschinenfabrik Reinhausen GmbH.

Authorized Personnel

- Specifically trained by the company for special maintenance tasks.

Personal Protective Equipment (PPE)

- Always wear the required PPE to minimize health risks.

- Avoid using damaged PPE.

- Types of PPE include:

- Protective Clothing: Close-fitting to prevent entanglement.

- Safety Shoes: Protect against heavy objects and slipping.

- Safety Glasses: Shield eyes from debris and liquids.

- Visor: Additional facial protection from splashes and debris.

- Hard Hat: Protects against falling objects.

- Hearing Protection: Safeguards against noise damage.

- Protective Gloves: Defend against thermal, mechanical, and electrical hazards.

Product Description of On-Load Tap-Changer

- Used to adjust transformer transmission ratios without interrupting load flow.

- Functions by responding to control impulses to adapt to operating conditions.

Setup/Versions

- Main components include:

- Transformer tank, motor-drive unit, vertical and horizontal drive shafts, on-load tap-changer, oil conservator, and protective relays.

Pipe Connections

- Multiple pipe connections serve functions such as draining and pressure equalization.

- Pipe Connection Q: Closed with a cover; used for supervisory device connections.

- Pipe Connection S: Draining function with a vent screw.

- Pipe Connection R: Connects protective relay and conservator.

- Pipe Connection E2: Used for pressure equalization and Buchholz relay connection.

Protective Devices

- Protective Relay: Trips when excessive flow is detected; essential for safety and de-energizing transformers.

- Pressure Monitoring Device (DW): Protects against excessive pressure with quick response.

- Rupture Disk: A pressure relief device responding to overpressure situations.

- Tap-Change Supervisory Device: Monitors drive shafts and the switching of the diverter switch.

- Temperature Monitoring: Ensures safe temperature levels of the insulating oil.

Drive Shaft Function

- Mechanically connects the drive and on-load tap-changer; utilizes bevel gears to redirect motion.

Design/Versions

- Made up of a square tube, coupling brackets, and bolts for secure connections.

- If the maximum axial offset exceeds 2472 mm, an intermediate bearing is necessary for stability.### Drive Shaft Configurations

- Drive shafts can either have a cardan joint or an insulator.

- Maximum permissible axial offset for various configurations ranges from 2° to 20°.

- Drive shafts without an intermediate bearing are for lengths (V1) less than or equal to 2472 mm.

- Use of intermediate bearings is mandatory for lengths exceeding specified limits:

- V1 > 2472 mm requires intermediate bearing for shafts without insulator.

- V1 > 2564 mm for drive shafts with cardan joints without insulator.

- V1 > 2772 mm for drive shafts with cardan joints with insulator.

Commissioning Process

- Ensure no ignition sources are present in the vicinity to prevent explosions.

- Only use approved insulating fluids to avoid damage to the tap-changer.

- Check for proper flange attachment for pressure relief device; operation without it is not permitted.

- Establish equal pressure in oil compartments before starting evacuation process.

- Fill the on-load tap-changer with new insulating fluid at designated pipe connections.

Bleeding Procedures

- Open all valves before bleeding air from the on-load tap-changer and suction pipe.

- Ensuring complete bleeding of the suction pipe is essential for insulation capability.

- Seal all openings securely after bleeding to maintain system integrity.

Motor-Drive Unit Checks

- Ensure the on-load tap-changer is immersed in insulating fluid before activation.

- Function checks must be performed according to manufacturer's operating instructions.

- Motor-drive unit coupling must be accurately inspected to prevent damage.

Protective Relay Testing

- Conduct tests before transformer commissioning to confirm protective relay functionality.

- Ensure grounding during tests and that the transformer remains de-energized.

- Conduct passive and active protection tests by simulating operational conditions.

Pressure Monitoring Device Examination

- Ground the transformer and ensure de-energization during testing.

- Follow active and passive protection tests for the pressure monitoring device prior to commissioning.

Handling Emergencies

- Operation of the motor-drive unit with a hand crank should only occur under strict conditions.

- Unauthorized operation may result in severe injury or death.

- Avoid completion of tap-change operations electrically if initiated manually.

- If the hand crank is difficult to operate, stop immediately to prevent damage.

Fault Elimination Procedures

- Removal of the on-load tap-changer head cover must be done carefully to avoid explosions.

- De-energize all circuits prior to maintenance work to ensure safety.

- Inspect on-load tap-changer and transformer immediately if protective relays trip to prevent further damage.

Introduction

- Operating instructions cover operation, fault management, and maintenance of the VACUTAP® VM 300 on-load tap-changer.

- Manufacturer: Maschinenfabrik Reinhausen GmbH, based in Regensburg, Germany.

- Important to retain related documents such as unpacking instructions, routine test reports, and order confirmations for completeness.

- Technical communication includes hazard warnings and detailed instructions to ensure safety in operation.

Safety

- Emphasizes the importance of familiarizing oneself with the product and safety instructions to avoid function-related dangers.

- Appropriate use is limited to electrical energy systems; must match specifications in official technical documents.

- On-load tap-changer operates without interrupting load flow, suitable only for designated transformers.

- Inappropriate use, including operating under non-compliant electrical conditions, poses risks to safety and can damage the product.

Personal Protective Equipment

- Use of personal protective equipment (PPE) is mandatory to avoid accidents, including helmets and gloves.

- Loose clothing and jewelry should not be worn to prevent entanglement; hair should be secured.

Operational Guidelines

- Regular checks of operational reliability and maintenance as per guidelines ensure continued safety and functionality.

- Ensure well-lit and organized work environments to prevent accidents.

- Do not perform operations in areas with explosion risks; adhere to explosion protection measures.

Hazard Communication

- Warning labels indicate potential dangers and required precautions; maintaining visibility and legibility is crucial.

- Different signal words indicate levels of risk: DANGER (life-threatening), WARNING (serious injury), CAUTION (minor injury), and NOTICE (property damage).

Ambient and Operational Conditions

- Must operate within specified ambient conditions for reliable functionality.

- Use only approved insulating fluids, lubricants, and operating materials to prevent malfunctions and enhance safety.

Maintenance and Inspection

- Scheduled inspections and maintenance activities as indicated in the technical file are critical for safe operation.

- Proper maintenance practices can mitigate risks associated with wear and tear of components.

Documentation and Communication

- Retain access to all technical and supporting documents for reference, enhancing understanding and effective operational practices.

- Communication of important details is structured clearly for better comprehension and adherence to procedures.### Modifications and Conversions

- Unauthorized modifications can lead to personal injuries, material damage, or operational faults.

- Consult Maschinenfabrik Reinhausen GmbH before making any changes.

Spare Parts

- Using unapproved spare parts can cause physical injury and malfunctions.

- Only utilize spare parts that are authorized by Maschinenfabrik Reinhausen GmbH.

Personnel Qualification

- Assembly and maintenance responsibilities require qualified personnel.

Electrically Skilled Person

- Must have technical qualifications, knowledge of standards, and safety regulations.

- Capable of identifying and avoiding potential dangers and can perform work on electrical systems.

Electrically Trained Persons

- Receive guidance from electrically skilled personnel regarding tasks and potential dangers.

Operator Responsibilities

- Operate the product according to the technical file and receive training on specific tasks and dangers.

Technical Service

- Maintenance and repairs should ideally be performed by the Technical Service department of Maschinenfabrik Reinhausen GmbH.

Authorized Personnel

- Specifically trained by the company for special maintenance tasks.

Personal Protective Equipment (PPE)

- Always wear the required PPE to minimize health risks.

- Avoid using damaged PPE.

- Types of PPE include:

- Protective Clothing: Close-fitting to prevent entanglement.

- Safety Shoes: Protect against heavy objects and slipping.

- Safety Glasses: Shield eyes from debris and liquids.

- Visor: Additional facial protection from splashes and debris.

- Hard Hat: Protects against falling objects.

- Hearing Protection: Safeguards against noise damage.

- Protective Gloves: Defend against thermal, mechanical, and electrical hazards.

Product Description of On-Load Tap-Changer

- Used to adjust transformer transmission ratios without interrupting load flow.

- Functions by responding to control impulses to adapt to operating conditions.

Setup/Versions

- Main components include:

- Transformer tank, motor-drive unit, vertical and horizontal drive shafts, on-load tap-changer, oil conservator, and protective relays.

Pipe Connections

- Multiple pipe connections serve functions such as draining and pressure equalization.

- Pipe Connection Q: Closed with a cover; used for supervisory device connections.

- Pipe Connection S: Draining function with a vent screw.

- Pipe Connection R: Connects protective relay and conservator.

- Pipe Connection E2: Used for pressure equalization and Buchholz relay connection.

Protective Devices

- Protective Relay: Trips when excessive flow is detected; essential for safety and de-energizing transformers.

- Pressure Monitoring Device (DW): Protects against excessive pressure with quick response.

- Rupture Disk: A pressure relief device responding to overpressure situations.

- Tap-Change Supervisory Device: Monitors drive shafts and the switching of the diverter switch.

- Temperature Monitoring: Ensures safe temperature levels of the insulating oil.

Drive Shaft Function

- Mechanically connects the drive and on-load tap-changer; utilizes bevel gears to redirect motion.

Design/Versions

- Made up of a square tube, coupling brackets, and bolts for secure connections.

- If the maximum axial offset exceeds 2472 mm, an intermediate bearing is necessary for stability.### Drive Shaft Configurations

- Drive shafts can either have a cardan joint or an insulator.

- Maximum permissible axial offset for various configurations ranges from 2° to 20°.

- Drive shafts without an intermediate bearing are for lengths (V1) less than or equal to 2472 mm.

- Use of intermediate bearings is mandatory for lengths exceeding specified limits:

- V1 > 2472 mm requires intermediate bearing for shafts without insulator.

- V1 > 2564 mm for drive shafts with cardan joints without insulator.

- V1 > 2772 mm for drive shafts with cardan joints with insulator.

Commissioning Process

- Ensure no ignition sources are present in the vicinity to prevent explosions.

- Only use approved insulating fluids to avoid damage to the tap-changer.

- Check for proper flange attachment for pressure relief device; operation without it is not permitted.

- Establish equal pressure in oil compartments before starting evacuation process.

- Fill the on-load tap-changer with new insulating fluid at designated pipe connections.

Bleeding Procedures

- Open all valves before bleeding air from the on-load tap-changer and suction pipe.

- Ensuring complete bleeding of the suction pipe is essential for insulation capability.

- Seal all openings securely after bleeding to maintain system integrity.

Motor-Drive Unit Checks

- Ensure the on-load tap-changer is immersed in insulating fluid before activation.

- Function checks must be performed according to manufacturer's operating instructions.

- Motor-drive unit coupling must be accurately inspected to prevent damage.

Protective Relay Testing

- Conduct tests before transformer commissioning to confirm protective relay functionality.

- Ensure grounding during tests and that the transformer remains de-energized.

- Conduct passive and active protection tests by simulating operational conditions.

Pressure Monitoring Device Examination

- Ground the transformer and ensure de-energization during testing.

- Follow active and passive protection tests for the pressure monitoring device prior to commissioning.

Handling Emergencies

- Operation of the motor-drive unit with a hand crank should only occur under strict conditions.

- Unauthorized operation may result in severe injury or death.

- Avoid completion of tap-change operations electrically if initiated manually.

- If the hand crank is difficult to operate, stop immediately to prevent damage.

Fault Elimination Procedures

- Removal of the on-load tap-changer head cover must be done carefully to avoid explosions.

- De-energize all circuits prior to maintenance work to ensure safety.

- Inspect on-load tap-changer and transformer immediately if protective relays trip to prevent further damage.

Introduction

- Operating instructions cover operation, fault management, and maintenance of the VACUTAP® VM 300 on-load tap-changer.

- Manufacturer: Maschinenfabrik Reinhausen GmbH, based in Regensburg, Germany.

- Important to retain related documents such as unpacking instructions, routine test reports, and order confirmations for completeness.

- Technical communication includes hazard warnings and detailed instructions to ensure safety in operation.

Safety

- Emphasizes the importance of familiarizing oneself with the product and safety instructions to avoid function-related dangers.

- Appropriate use is limited to electrical energy systems; must match specifications in official technical documents.

- On-load tap-changer operates without interrupting load flow, suitable only for designated transformers.

- Inappropriate use, including operating under non-compliant electrical conditions, poses risks to safety and can damage the product.

Personal Protective Equipment

- Use of personal protective equipment (PPE) is mandatory to avoid accidents, including helmets and gloves.

- Loose clothing and jewelry should not be worn to prevent entanglement; hair should be secured.

Operational Guidelines

- Regular checks of operational reliability and maintenance as per guidelines ensure continued safety and functionality.

- Ensure well-lit and organized work environments to prevent accidents.

- Do not perform operations in areas with explosion risks; adhere to explosion protection measures.

Hazard Communication

- Warning labels indicate potential dangers and required precautions; maintaining visibility and legibility is crucial.

- Different signal words indicate levels of risk: DANGER (life-threatening), WARNING (serious injury), CAUTION (minor injury), and NOTICE (property damage).

Ambient and Operational Conditions

- Must operate within specified ambient conditions for reliable functionality.

- Use only approved insulating fluids, lubricants, and operating materials to prevent malfunctions and enhance safety.

Maintenance and Inspection

- Scheduled inspections and maintenance activities as indicated in the technical file are critical for safe operation.

- Proper maintenance practices can mitigate risks associated with wear and tear of components.

Documentation and Communication

- Retain access to all technical and supporting documents for reference, enhancing understanding and effective operational practices.

- Communication of important details is structured clearly for better comprehension and adherence to procedures.### Modifications and Conversions

- Unauthorized modifications can lead to personal injuries, material damage, or operational faults.

- Consult Maschinenfabrik Reinhausen GmbH before making any changes.

Spare Parts

- Using unapproved spare parts can cause physical injury and malfunctions.