Questions and Answers

What characteristic of aluminium allows it to be alloyed for aircraft construction?

Which aluminium alloy series indicates 99% minimum aluminium content with no major alloying elements?

What is the primary benefit of alloying aluminium with elements like copper or zinc?

What differentiates wrought aluminium alloys from cast aluminium alloys?

Signup and view all the answers

In the alpha-numeric designation for wrought aluminium alloys, what does the first digit represent?

Signup and view all the answers

What is the role of the second digit in the designation of wrought aluminium alloys in the 1xxx Series?

Signup and view all the answers

Why is the 1xxx Series considered unique among wrought aluminium alloys?

Signup and view all the answers

Which of the following is NOT commonly used as an alloying element for aluminium?

Signup and view all the answers

Which alloy series primarily uses manganese as its principal alloying element?

Signup and view all the answers

What implication does a second digit of zero in an alloy designation indicate?

Signup and view all the answers

Which series of aluminium alloys is known for being non-heat-treatable and offers moderate strength?

Signup and view all the answers

What is a primary drawback of aluminium-copper alloys?

Signup and view all the answers

What role does silicon play in the 4xxx Series aluminium alloys?

Signup and view all the answers

Which alloy series designation indicates the presence of zinc as the principal alloying element?

Signup and view all the answers

What is the primary function of clad aluminium alloy in aircraft construction?

Signup and view all the answers

Which heat treatment process is used to allow the alloying elements to mix with the base metal?

Signup and view all the answers

What is the consequence of improperly removing an alloy from the furnace during solution heat treatment?

Signup and view all the answers

Which of the following characteristics is NOT commonly associated with 5xxx Series alloys?

Signup and view all the answers

Which aluminium alloy is known for its high tensile strength and is commonly used in aircraft components?

Signup and view all the answers

What is one of the main requirements when heat treating an alloy in solution heat treatment?

Signup and view all the answers

What is the unique role of the last two digits in the alloy designation system?

Signup and view all the answers

What method is used to improve the corrosion resistance of magnesium alloys?

Signup and view all the answers

What is a significant risk when machining magnesium?

Signup and view all the answers

Which property of titanium makes it highly desirable for aerospace applications?

Signup and view all the answers

What is the primary use of Monel in aircraft applications?

Signup and view all the answers

What distinguishes Inconel from Monel?

Signup and view all the answers

Why is copper generally not used as a structural material in aircraft construction?

Signup and view all the answers

What contribution does solution heat treatment provide to magnesium alloys?

Signup and view all the answers

What chemical process is necessary for utilizing titanium before its application?

Signup and view all the answers

Which copper alloy is mainly used in electrical components due to its high conductivity?

Signup and view all the answers

What happens to the hardness and yield strength of magnesium alloys after precipitation heat treatment?

Signup and view all the answers

What is the effect of excessive precipitation in aluminium alloys?

Signup and view all the answers

Which quenching medium is most appropriate for aluminium alloys?

Signup and view all the answers

What is the term for the process in which an alloy is allowed to cool at room temperature?

Signup and view all the answers

What happens if clad aluminium is exposed to excessive heat during annealing?

Signup and view all the answers

Which designation indicates that an aluminium alloy has undergone solution heat treatment followed by natural ageing?

Signup and view all the answers

How is the process of artificially aged alloys described?

Signup and view all the answers

What is the typical limitation on heat treatments for clad materials?

Signup and view all the answers

What does the letter designation 'H' indicate in aluminium alloys?

Signup and view all the answers

Which of the following processes is specifically associated with increasing the alloy's hardness and strength?

Signup and view all the answers

What is the consequence of strain-hardening aluminium alloys?

Signup and view all the answers

In what form can magnesium alloys be used?

Signup and view all the answers

What is the primary goal of the annealing process with aluminium alloys?

Signup and view all the answers

What can result from leaving salt residue on an alloy after rinsing?

Signup and view all the answers

Which of the following indicates a heat treatment that requires rapid cooling followed by artificial aging?

Signup and view all the answers

Study Notes

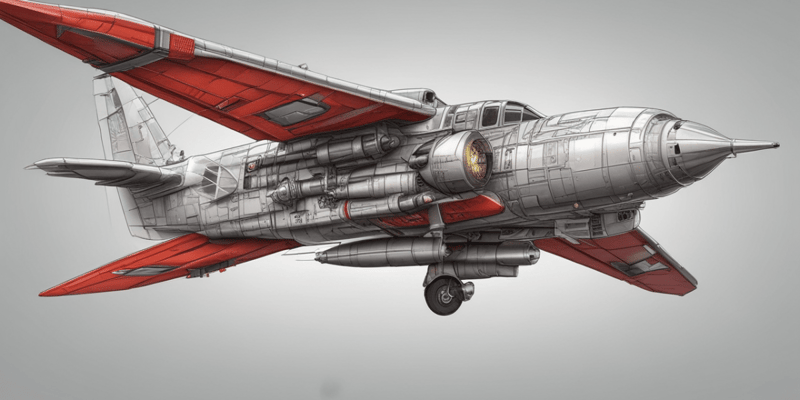

Non-Ferrous Metals

- Non-ferrous metals are defined as metals that do not contain iron.

- Common non-ferrous metals used in aircraft include aluminium, copper, titanium, and magnesium.

Aluminium Characteristics

- Aluminium is a silver-white metallic element derived from bauxite through electrolysis.

- Pure aluminium has insufficient strength for aircraft use but significantly increases in strength when alloyed with elements like copper or zinc, achieving strength comparable to steel at one-third the weight.

Aluminium Alloys

- Aluminium alloys are classified by the principal alloying elements:

- Copper (2xxx Series)

- Magnesium (5xxx Series)

- Manganese (3xxx Series)

- Zinc (7xxx Series)

- Silicon (4xxx Series)

- Two main classes of aluminium alloys:

- Wrought: Rolled or extruded shapes, most commonly used in aircraft.

- Cast: Poured into molds and solidified.

Wrought Aluminium Alloys Designation System

- Alloys identified with a four-digit index where:

- 1xxx Series indicates pure aluminium (99% minimum).

- 2xxx to 9xxx Series indicate various alloying elements and modifications.

Specific Alloy Series

- 1xxx Series: Pure aluminium, exhibiting high formability and electrical conductivity.

- 2xxx Series: Copper alloys, notable for high strength but susceptible to inter granular corrosion.

- 3xxx Series: Manganese alloys, non-heat-treatable with moderate strength.

- 4xxx Series: Silicon alloys with lower melting points, ideal for welding.

- 5xxx Series: Magnesium alloys offering good corrosion resistance.

- 6xxx Series: Combination of magnesium and silicon, features medium strength and good forming properties.

- 7xxx Series: Zinc alloys that are harder and stronger, commonly used in structural applications.

- 8xxx Series: High strength and elasticity for aerospace applications.

- 9xxx Series: Currently unassigned.

Alclad Aluminium Alloy

- Alclad features a pure aluminium coating on heat-treated alloys to enhance corrosion resistance, although it is vulnerable to scratches.

Heat Treatment Processes

- Heat treatment improves metal properties, making them harder, stronger, or softer, varying by temperature and cooling rates.

- Two primary methods for aluminium alloys:

- Solution Heat Treatment: Involves heating to allow alloying elements to mix, then rapidly cooling (quenching) to prevent precipitation of large grains.

- Precipitation Heat Treatment: Ageing process to increase strength over time at room temperature or accelerated through reheating.

Annealing and Hardness Designations

- Annealing softens metal and reduces internal stress, contrasting with hardening processes.

- Hardness and temper are indicated by designations (T for heat-treated alloys; H for strain-hardened).

Magnesium Alloys

- Magnesium is lightweight, making it highly suitable for aircraft applications despite high corrosion susceptibility.

- Strengthened by solution heat treatment and treated to increase resistance to shock and yield strength.

Titanium Alloys

- Titanium features high strength-to-weight ratio and excellent corrosion resistance, particularly in aerospace applications.

Nickel and Its Alloys

- Nickel is used in significant alloys:

- Monel: Nickel and copper alloy, weldable with good strength and toughness.

- Inconel: Nickel and chromium alloy, suitable for high-temperature environments in turbine engines.

Copper and Its Alloys

- Copper is primarily used for electrical wiring due to excellent conductivity.

- Common copper alloys include:

- Brass: Utilized in electrical components.

- Bronze: Found in bushings and bearings.

- Beryllium Copper: Hazardous due to airborne contaminants produced during grinding or machining.

Safety Notes

- Beryllium copper is classified as a hazardous material due to health risks associated with its dust and fumes.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

This quiz explores the quenching process of aluminium alloys, detailing the importance of cooling rates and the effects of excessive precipitation. Understanding how quenching mediums influence alloy integrity and the risk of inter granular corrosion is essential. Test your knowledge on the critical aspects of alloy treatment and metal chemistry.