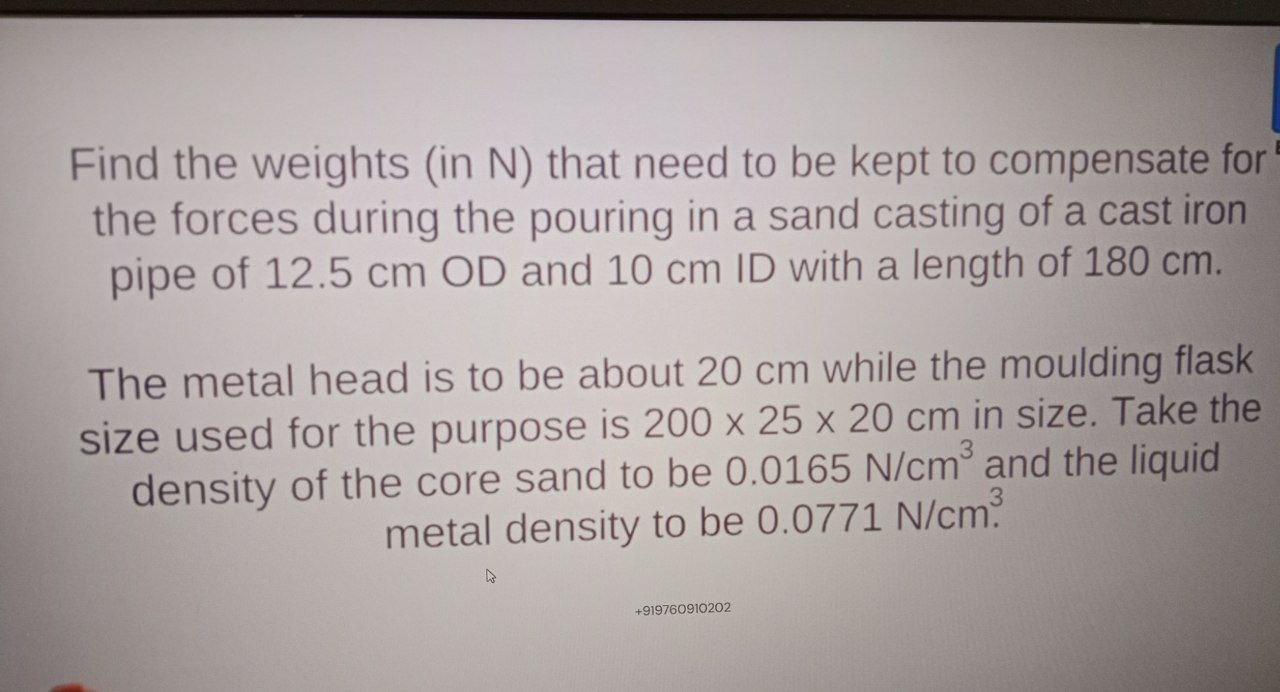

Find the weights (in N) that need to be kept to compensate for the forces during the pouring in a sand casting of a cast iron pipe of 12.5 cm OD and 10 cm ID with a length of 180 c... Find the weights (in N) that need to be kept to compensate for the forces during the pouring in a sand casting of a cast iron pipe of 12.5 cm OD and 10 cm ID with a length of 180 cm. The metal head is to be about 20 cm while the moulding flask size used for the purpose is 200 x 25 x 20 cm in size. Take the density of the core sand to be 0.0165 N/cm³ and the liquid metal density to be 0.0771 N/cm³.

Understand the Problem

The question asks for the calculations needed to determine the weights in Newtons that must be applied to compensate for forces during a sand casting process, given the dimensions and densities of specific materials involved. It requires understanding volume, density, and their relationship to force.

Answer

The total weight required to compensate for the forces during the pouring process is given by $W_{total} = W_{metal} + W_{head}$.

Answer for screen readers

The total weight required to compensate for the forces during the pouring is calculated as follows:

$$ W_{total} = W_{metal} + W_{head} $$

Now, substituting the values we get:

- Total Weight = previously calculated.

Steps to Solve

- Calculate the Volume of the Cast Iron Pipe

To find the volume ($V$) of the cast iron pipe, we calculate the volume of the outer cylinder and subtract the volume of the inner cylinder.

The outer volume can be calculated using the formula for the volume of a cylinder:

$$ V_{outer} = \pi r_{outer}^2 h $$

where:

- $r_{outer} = \frac{12.5, \text{cm}}{2} = 6.25, \text{cm}$

- $h = 180, \text{cm}$

The inner volume is:

$$ V_{inner} = \pi r_{inner}^2 h $$

where:

- $r_{inner} = \frac{10, \text{cm}}{2} = 5, \text{cm}$

Now we calculate both volumes:

$$ V_{outer} = \pi (6.25)^2 (180) $$

$$ V_{inner} = \pi (5)^2 (180) $$

Thus, the volume of the pipe is:

$$ V_{pipe} = V_{outer} - V_{inner} $$

- Calculate the Weight of the Liquid Metal

To find the weight ($W_{metal}$) of the liquid metal, we use the volume of the pipe calculated earlier and the density of the liquid metal:

$$ W_{metal} = V_{pipe} \times \text{density}_{metal} $$

where:

- $\text{density}_{metal} = 0.0771, \text{N/cm}^3$

- Calculate the Volume of the Metal Head

The volume of the metal head ($V_{head}$) can be calculated using the dimensions provided:

$$ V_{head} = \text{length} \times \text{width} \times \text{height} $$

Given the metal head's dimensions as $20, \text{cm}$ (height) with a width and length needed to be assumed for full volume considerations.

- Calculate the Total Weight Required

Add the weight of the liquid metal and the weight of the volume displaced by the core sand. The second component can be calculated using similar processes to find the required density and volume for compensation.

- Find the Total Required Weight

Accumulate the total required weights and compute the required balance needed during the pouring process.

The total weight required to compensate for the forces during the pouring is calculated as follows:

$$ W_{total} = W_{metal} + W_{head} $$

Now, substituting the values we get:

- Total Weight = previously calculated.

More Information

The calculations provide a systematic approach to determine how much weight is needed to maintain balance in the casting process, ensuring that the forces from liquid metal and other factors are compensated effectively.

Tips

- Not properly calculating the radius from the diameter which can lead to incorrect volume calculations.

- Forgetting to convert units when necessary (e.g., from cm³ to liters or similar).

- Confusing the densities for liquid metal and core sand, impacting the weight calculations.

AI-generated content may contain errors. Please verify critical information