Podcast

Questions and Answers

¿Qué tipo de sistemas automatizados ayuda a almacenar y recuperar elementos de matrices verticales?

¿Qué tipo de sistemas automatizados ayuda a almacenar y recuperar elementos de matrices verticales?

¿Qué tipo de tecnología ayuda a rastrear unidades individuales de inventario a medida que se mueven de un lugar a otro?

¿Qué tipo de tecnología ayuda a rastrear unidades individuales de inventario a medida que se mueven de un lugar a otro?

¿Qué estrategia busca minimizar la distancia de viaje entre ubicaciones de selección?

¿Qué estrategia busca minimizar la distancia de viaje entre ubicaciones de selección?

¿Qué tipo de tecnología permite una visibilidad en tiempo real de los niveles de inventario y automatiza tareas rutinarias en un almacén?

¿Qué tipo de tecnología permite una visibilidad en tiempo real de los niveles de inventario y automatiza tareas rutinarias en un almacén?

Signup and view all the answers

¿Cuál es uno de los beneficios de implementar sistemas automatizados en operaciones de almacén?

¿Cuál es uno de los beneficios de implementar sistemas automatizados en operaciones de almacén?

Signup and view all the answers

¿Qué es el control de inventario?

¿Qué es el control de inventario?

Signup and view all the answers

¿Por qué es importante la organización de almacén en el control de inventario?

¿Por qué es importante la organización de almacén en el control de inventario?

Signup and view all the answers

¿Qué papel desempeña el análisis ABC en la organización del almacén?

¿Qué papel desempeña el análisis ABC en la organización del almacén?

Signup and view all the answers

¿Qué beneficios adicionales aporta la organización eficiente en un almacén?

¿Qué beneficios adicionales aporta la organización eficiente en un almacén?

Signup and view all the answers

¿Por qué es fundamental el diseño organizado de un almacén?

¿Por qué es fundamental el diseño organizado de un almacén?

Signup and view all the answers

Study Notes

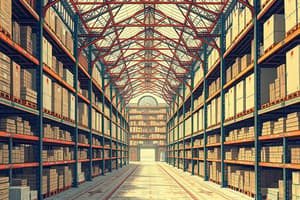

Warehouse Organization and Inventory Control

Inventory control is a process of managing inventory by monitoring stock levels and ordering goods when needed. This helps ensure that businesses have the right amount of products available to meet customers' demand while avoiding overstocking or understocking. Effective inventory management requires proper organization within warehouses to facilitate efficient handling of materials and ease of access to them. Here, we will discuss various aspects of warehouse organization related to inventory control.

Importance of Warehouse Organization

Warehouse organization plays a crucial role in inventory control. It ensures that products are stored efficiently, allowing for easy retrieval and restocking. Proper storage can reduce labor costs associated with manual search and recovery tasks, minimize product damage, and prevent loss due to spoilage or expiration. Additionally, organized warehousing increases employee efficiency and productivity, leading to faster order fulfillment and reduced lead times.

Designing an Organized Warehouse Layout

Designing an organized layout involves arranging shelves in a specific pattern based on different criteria such as:

ABC Analysis

ABC analysis categorizes items into three groups - A for high-volume items, B for medium-volume items, and C for low-volume items. Shelves are arranged according to this classification, ensuring common items are easily accessible.

Storage Media Types

Different types of storage media like pallets, bins, totes, and racks require different dimensions and arrangements. Choosing the appropriate storage media type depends on the size, weight, and volume of the items being stored.

Product Flow

Product flow optimization aims to minimize travel distance between picking locations. This can be achieved through strategies like cross-docking, where incoming goods are immediately shipped out, reducing storage requirement and associated costs.

Layout Considerations

Layouts must allow for smooth material handling operations. They should accommodate equipment used in the operation such as conveyors, forklifts, and automated systems.

Implementing Automation in Warehouse Operations

Automating certain processes in the warehouse can significantly improve inventory control. Examples include:

Barcode Scanning Systems

Barcode scanners help track individual units of inventory as they move from one location to another. Real-time tracking data allows for accurate inventory counts and reduces errors.

Robotic Sortation Systems

These systems automatically sort items based on predefined rules, speeding up the sorting process and improving accuracy.

Automated Storage and Retrieval Systems (ASRS)

ASRS uses robots to store and retrieve items from vertical arrays, significantly increasing storage capacity and reducing manual labor requirements.

Warehouse Management Software (WMS)

WMS tracks stock movement, provides real-time visibility into inventory levels, and automates many routine tasks, thereby enhancing overall inventory control.

By implementing these technologies, businesses can streamline their warehouse operations, increase efficiency, and better manage their inventories. Furthermore, incorporating automation enables companies to adapt quickly to changing inventory demands and market conditions.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Description

Explore the importance of warehouse organization in inventory control, including designing an organized warehouse layout and implementing automation in warehouse operations. Learn how efficient warehouse organization can lead to cost savings, increased productivity, and better inventory management.