Podcast

Questions and Answers

How does the direction of twist in yarn affect the prominence of twill?

How does the direction of twist in yarn affect the prominence of twill?

When the yarn twist direction matches the twill direction, the prominence is reduced; when they are opposite, the prominence is increased.

What are some advantages of using twill weaves?

What are some advantages of using twill weaves?

Advantages include interesting surface texture, better wrinkle recovery, and durability due to high thread counts.

In what applications are twill weaves commonly found?

In what applications are twill weaves commonly found?

Twill weaves are used in applications like drill cloth, denim, khaki uniforms, and soft furnishings.

What distinguishes satin from sateen in terms of weave orientation?

What distinguishes satin from sateen in terms of weave orientation?

What is a key characteristic of satin and sateen weaves?

What is a key characteristic of satin and sateen weaves?

How do move numbers aid in the construction of satin and sateen weaves?

How do move numbers aid in the construction of satin and sateen weaves?

What challenges are associated with satin and sateen weaves regarding seam strength?

What challenges are associated with satin and sateen weaves regarding seam strength?

Why are twill weaves seldom printed?

Why are twill weaves seldom printed?

What role does the move number play in laying out the design for satin or sateen weaves?

What role does the move number play in laying out the design for satin or sateen weaves?

Give one rule for selecting a move number in satin or sateen weaves.

Give one rule for selecting a move number in satin or sateen weaves.

For a 4/1 Satin weave, what is the correct move number selected and why?

For a 4/1 Satin weave, what is the correct move number selected and why?

What is the implication of using a move number that is one less than the repeat size of the weave?

What is the implication of using a move number that is one less than the repeat size of the weave?

In the case of a 4/1 Satin weave with Move No. 3, how is the second warp end filled?

In the case of a 4/1 Satin weave with Move No. 3, how is the second warp end filled?

What ensures that the design does not resemble a twill weave in satin/sateen construction?

What ensures that the design does not resemble a twill weave in satin/sateen construction?

What visual pattern is followed in filling the warp ends after determining the move number?

What visual pattern is followed in filling the warp ends after determining the move number?

How does factorization of the repeat size influence move number selection?

How does factorization of the repeat size influence move number selection?

What does the numerator represent in the twill fraction?

What does the numerator represent in the twill fraction?

How does the firmness of a twill weave relate to the number of intersections?

How does the firmness of a twill weave relate to the number of intersections?

In a balanced twill weave, what is the relationship between the numerator and denominator?

In a balanced twill weave, what is the relationship between the numerator and denominator?

What characterizes an irregular cross twill weave?

What characterizes an irregular cross twill weave?

What are the defining features of warp faced twill?

What are the defining features of warp faced twill?

How do yarn characteristics influence the prominence of twill weaves?

How do yarn characteristics influence the prominence of twill weaves?

What impact do longer floats in twill weaves have?

What impact do longer floats in twill weaves have?

What effect do warp and weft thread densities have on twill prominence?

What effect do warp and weft thread densities have on twill prominence?

What differentiates Regular Weft Sateen from Irregular Weft Sateen?

What differentiates Regular Weft Sateen from Irregular Weft Sateen?

Describe the significance of the 'end' in the given satin and sateen constructions.

Describe the significance of the 'end' in the given satin and sateen constructions.

In the context of satin fabrics, what does a '3/1' or '5/1' designation represent?

In the context of satin fabrics, what does a '3/1' or '5/1' designation represent?

Explain the term 'irregular satin' as used in the fabric classifications.

Explain the term 'irregular satin' as used in the fabric classifications.

What are 'Standard Irregular Satin and Sateen' fabrics characterized by?

What are 'Standard Irregular Satin and Sateen' fabrics characterized by?

What is the pattern for marking the first end in a 4/1 (5-End) Satin with Move No. 2?

What is the pattern for marking the first end in a 4/1 (5-End) Satin with Move No. 2?

How do you determine the counting sequence for the second end in a 4/1 (5-End) Satin with Move No. 2?

How do you determine the counting sequence for the second end in a 4/1 (5-End) Satin with Move No. 2?

In the 1/4 (5-End) Sateen with Move No. 2, how is the second end filled?

In the 1/4 (5-End) Sateen with Move No. 2, how is the second end filled?

What marking is done to the adjacent right box of the second end in a 1/4 (5-End) Sateen with Move No. 2?

What marking is done to the adjacent right box of the second end in a 1/4 (5-End) Sateen with Move No. 2?

Describe the filling process for the third end in a 4/1 (5-End) Satin with Move No. 2.

Describe the filling process for the third end in a 4/1 (5-End) Satin with Move No. 2.

What is the final step in completing the repeat for the 4/1 (5-End) Satin with Move No. 2?

What is the final step in completing the repeat for the 4/1 (5-End) Satin with Move No. 2?

How is the filling of the third end conducted in a 1/4 (5-End) Sateen with Move No. 3?

How is the filling of the third end conducted in a 1/4 (5-End) Sateen with Move No. 3?

Explain the significance of the Move No. in the context of filling the ends in a weave.

Explain the significance of the Move No. in the context of filling the ends in a weave.

What is the process to fill the second end after the first end is completed?

What is the process to fill the second end after the first end is completed?

How is the direction of diagonal lines determined in satin/sateen weaves?

How is the direction of diagonal lines determined in satin/sateen weaves?

What distinguishes regular satin/sateen weave from irregular satin/sateen weave?

What distinguishes regular satin/sateen weave from irregular satin/sateen weave?

What applications are commonly associated with satin weaves?

What applications are commonly associated with satin weaves?

Define warp satin and its types.

Define warp satin and its types.

How does the counting process for filling subsequent ends start?

How does the counting process for filling subsequent ends start?

What is the significance of move numbers in regular satin/sateen weaves?

What is the significance of move numbers in regular satin/sateen weaves?

Explain the role of Move #2 and Move #3 in creating different satin and sateen variations.

Explain the role of Move #2 and Move #3 in creating different satin and sateen variations.

Flashcards

Twill prominence

Twill prominence

How noticeable the diagonal lines (twill) are in the fabric.

Yarn twist direction

Yarn twist direction

The direction of the twist in the yarn (either Z or S).

Z twist and Z twill

Z twist and Z twill

A Z twist yarn in a Z twill weave shows less prominence (fewer diagonal lines).

S twist and S twill

S twist and S twill

Signup and view all the flashcards

Satin Weave

Satin Weave

Signup and view all the flashcards

Sateen Weave

Sateen Weave

Signup and view all the flashcards

Move Number (Satin/Sateen)

Move Number (Satin/Sateen)

Signup and view all the flashcards

Applications of Twill

Applications of Twill

Signup and view all the flashcards

Twill Weave Firmness

Twill Weave Firmness

Signup and view all the flashcards

Balanced Twill Fraction

Balanced Twill Fraction

Signup and view all the flashcards

Irregular Twill Fraction

Irregular Twill Fraction

Signup and view all the flashcards

Twill Repeat

Twill Repeat

Signup and view all the flashcards

Warp Faced Twill

Warp Faced Twill

Signup and view all the flashcards

Weft Faced Twill

Weft Faced Twill

Signup and view all the flashcards

Yarn Effect on Twill

Yarn Effect on Twill

Signup and view all the flashcards

Satin/Sateen Weave

Satin/Sateen Weave

Signup and view all the flashcards

Move Number

Move Number

Signup and view all the flashcards

Weave Repeat

Weave Repeat

Signup and view all the flashcards

Move Number Restrictions

Move Number Restrictions

Signup and view all the flashcards

4/1 Satin (5 ends)

4/1 Satin (5 ends)

Signup and view all the flashcards

Filling the Second End

Filling the Second End

Signup and view all the flashcards

Determining the next end

Determining the next end

Signup and view all the flashcards

Interlacing Pattern

Interlacing Pattern

Signup and view all the flashcards

4/1 Satin Weave

4/1 Satin Weave

Signup and view all the flashcards

Satin with Move No.2

Satin with Move No.2

Signup and view all the flashcards

1/4 Sateen Weave

1/4 Sateen Weave

Signup and view all the flashcards

Sateen with Move No.2

Sateen with Move No.2

Signup and view all the flashcards

Warp Ends

Warp Ends

Signup and view all the flashcards

Weft Ends

Weft Ends

Signup and view all the flashcards

Weave Pattern

Weave Pattern

Signup and view all the flashcards

Weft Sateen

Weft Sateen

Signup and view all the flashcards

Regular Weft Sateen

Regular Weft Sateen

Signup and view all the flashcards

Irregular Weft Sateen

Irregular Weft Sateen

Signup and view all the flashcards

Standard Irregular Satin

Standard Irregular Satin

Signup and view all the flashcards

Plain Stitched Hopsacks

Plain Stitched Hopsacks

Signup and view all the flashcards

Regular Satin/Sateen Weave

Regular Satin/Sateen Weave

Signup and view all the flashcards

Irregular Satin/Sateen Weave

Irregular Satin/Sateen Weave

Signup and view all the flashcards

Warp Satin

Warp Satin

Signup and view all the flashcards

Regular Warp Satin

Regular Warp Satin

Signup and view all the flashcards

Irregular Warp Satin

Irregular Warp Satin

Signup and view all the flashcards

Move Number (in weaving)

Move Number (in weaving)

Signup and view all the flashcards

Study Notes

Plain Weaves

- Plain weave, also known as calico or tabby weave, is the simplest weave with a repeat size of 2.

- It features a maximum number of binding points.

- It has no right or wrong side, and doesn't stretch lengthwise or crosswise.

- It is less absorbent and creases easily compared to other weaves.

- It's versatile and hard-wearing, making it durable.

Twill Weaves

- Twill weave is a basic weave type distinguished by pronounced diagonal lines running along the fabric's width.

- In a regular twill, the diagonal lines repeat regularly, usually at a 45-degree angle.

- Twill weaves may vary in angle from a gentle slope to a steep slope.

- To be a twill, each warp thread must float over a minimum of two picks.

- Fabric characteristics can include: diagonal lines, directional orientation, and potentially a face/back orientation and interesting surface texture.

- Durability, wrinkle resistance, hardness, and a range of applications are also possible.

- Method of representation is done via fractions (e.g., 3/1, 2/1) where the numerator is the number of weft threads a warp thread overlaps and the denominator is the number of weft threads a warp thread underlaps within a repeat.

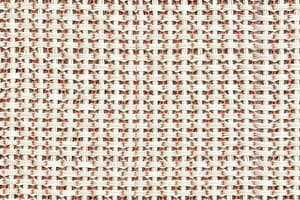

Satin & Sateen Weaves

- Satin is a warp-faced weave with warp threads more prominent, while Sateen is a weft-faced weave with weft threads more prominent.

- These are diagonally arranged weaves with few interlacing points, giving long floats and a lustrous appearance because fine, closely packed yarns are commonly used.

- Sateen and satin are used in diverse ways, including (but not limited to) denim, interlining, and dress materials.

- Sateen/satin weaves have a uniform structural characteristic.

- Method of construction uses move numbers (intervals of selection) to ensure consistent patterns, preventing twill-like streaks.

Plain Weave Derivatives

- Warp Rib, Weft Rib, Mock Rib, Simple Matt, Fancy Matt, and Dimity are various plain weave derivatives.

- Warp ribs create horizontal stripes, while weft ribs produce vertical stripes.

- Mock ribs are produced from filling a plain weave with two picks at the same time.

- Matt weaves are made by combining the plain weave in both warp and weft directions (e.g., 2x2, 3x3 Matt weaves)

- Dimity is a combination of various plain weaves and their derivatives, including warp ribs, mock ribs, or matt weaves.

Twill Weave Derivatives

- Pointed twills are created by combining right-hand and left-hand twills.

- Herringbone twills combine right and left hand twills, but reverse the pattern at the point of change in direction.

- Combined twills combine two or more twill weaves in unique patterns.

- Broken twills deliberately break the diagonal twill lines through reversing the twill factor.

- Transposed twill involves rearranging the original twill order, and elongated tweaks are formed at angles other than 45 degrees using differing warp and weft thread densities. They also use special methods in their creation.

- Curving the twill draft produces curved twill, which are made by curving the draft of any given twill weave.

Satin & Sateen Weave Derivatives

- Extended sateen/satin weaves extend the basic structures in the warp and/or weft directions.

- Satin-and-sateen stripes combine satin and sateen weaves to form striped patterns (horizontal or vertical).

- Satin-and-sateen checks combine these weaves to make checks.

- Rearranged twills (based on sateen weaves) rearrange the basic twill structure for unique patterns.

- Corkscrew twills are a specific type of rearranged twill.

- Twilled hopsacks are a type of hopsack weave.

Honeycomb Weaves

- Honeycomb weave fabrics are made by using threads that form ridges and hollows giving the fabric a cell-like appearance.

- Some types include: ordinary honeycombs, single ridge honeycombs, double ridge honeycombs, fancier honeycombs, and Brighton's honeycombs.

Checkerboard Weaves

- Checkerboard weaves are formed by combining two or more weaves (and variations) in a specific checkerboard pattern.

- The four sections of the weave usually have one of the differing weaves.

Huckaback Weaves

- Huckaback is a fabric using coarse absorbent linen or cotton.

- It includes plain weaves with floats, and various other variations in the patterns.

Crepe Fabrics

- Crepe fabrics are characterized by their irregularity and broken surface which is achieved through several methods, including: using crepe yarns, applying special finishes (mechanical or chemical), or through specially designed weave structures.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.