Podcast

Questions and Answers

How does the direction of yarn twist affect the prominence of twill patterns?

How does the direction of yarn twist affect the prominence of twill patterns?

When the direction of yarn twist is the same as the twill direction, prominence is reduced; when opposite, prominence increases.

What are some advantages of using twill weaves in fabrics?

What are some advantages of using twill weaves in fabrics?

Twill weaves offer interesting surface textures, better wrinkle recovery, and the ability to achieve high counts for durability.

Can you list a few applications where twill weaves are commonly utilized?

Can you list a few applications where twill weaves are commonly utilized?

Twill weaves are used in drill cloth, khaki uniforms, denim cloth, jeans, and soft furnishings.

What distinguishes satin weaves from sateen weaves?

What distinguishes satin weaves from sateen weaves?

Describe a characteristic of both satin and sateen weaves.

Describe a characteristic of both satin and sateen weaves.

What implications does the thread density have in satin and sateen weaves?

What implications does the thread density have in satin and sateen weaves?

What is the purpose of move numbers in the construction of satin and sateen weaves?

What is the purpose of move numbers in the construction of satin and sateen weaves?

Why might seam strength be a concern in satin and sateen weaves?

Why might seam strength be a concern in satin and sateen weaves?

What is the significance of the move number in weaving designs?

What is the significance of the move number in weaving designs?

List three rules for selecting the move number in satin/sateen weaves.

List three rules for selecting the move number in satin/sateen weaves.

If the weave is 4/1 satin, what is the repeat size?

If the weave is 4/1 satin, what is the repeat size?

Why can't move number 5 be selected for a 4/1 satin weave?

Why can't move number 5 be selected for a 4/1 satin weave?

For a 4/1 satin weave, which move numbers can be selected?

For a 4/1 satin weave, which move numbers can be selected?

Describe how to mark the first warp end for the 4/1 satin weave using move number 3.

Describe how to mark the first warp end for the 4/1 satin weave using move number 3.

In the marking process for the second end, what should be the starting point based on move number 3?

In the marking process for the second end, what should be the starting point based on move number 3?

How is the adjacent right box marked when filling the third warp end?

How is the adjacent right box marked when filling the third warp end?

What does the numerator and denominator of the twill fraction represent?

What does the numerator and denominator of the twill fraction represent?

How is the firmness of twill weave determined?

How is the firmness of twill weave determined?

What distinguishes balanced twill from irregular cross twill?

What distinguishes balanced twill from irregular cross twill?

What characterizes a warp faced twill?

What characterizes a warp faced twill?

How do thread densities affect twill prominence?

How do thread densities affect twill prominence?

What is the relation between the nature of yarn and twill prominence?

What is the relation between the nature of yarn and twill prominence?

Explain the impact of weave type on twill prominence.

Explain the impact of weave type on twill prominence.

What distinguishes plain weave from other types of weaves in terms of thread interlacing?

What distinguishes plain weave from other types of weaves in terms of thread interlacing?

What types of twill weave are characterized by the direction of yarn?

What types of twill weave are characterized by the direction of yarn?

List three characteristics of plain weave that enhance its durability.

List three characteristics of plain weave that enhance its durability.

How does the absorbency of plain weave compare to other weaves?

How does the absorbency of plain weave compare to other weaves?

What types of garments commonly utilize plain weave fabrics?

What types of garments commonly utilize plain weave fabrics?

Describe the primary visual characteristic of twill weave.

Describe the primary visual characteristic of twill weave.

What is the minimum requirement for the interlacing of threads in a twill weave?

What is the minimum requirement for the interlacing of threads in a twill weave?

Explain the difference between right-hand twill and left-hand twill.

Explain the difference between right-hand twill and left-hand twill.

What factors affect the firmness of woven structures like plain and twill weaves?

What factors affect the firmness of woven structures like plain and twill weaves?

What is the basic structure of the 4/1 (5-End) Satin weave?

What is the basic structure of the 4/1 (5-End) Satin weave?

How is the counting for Move No. 2 initiated in the 4/1 (5-End) Satin weave?

How is the counting for Move No. 2 initiated in the 4/1 (5-End) Satin weave?

In a 1/4 (5-End) Sateen with Move No. 2, what fills the first warp end?

In a 1/4 (5-End) Sateen with Move No. 2, what fills the first warp end?

What happens to the second end when filling it in a 1/4 (5-End) Sateen with Move No. 2?

What happens to the second end when filling it in a 1/4 (5-End) Sateen with Move No. 2?

Explain the marking process for the adjacent right box of the second end in a 4/1 (5-End) Satin weave.

Explain the marking process for the adjacent right box of the second end in a 4/1 (5-End) Satin weave.

Describe the process of filling subsequent ends in both the 4/1 Satin and 1/4 Sateen weaves.

Describe the process of filling subsequent ends in both the 4/1 Satin and 1/4 Sateen weaves.

For 1/4 (5-End) Sateen with Move No. 3, how does the marking begin?

For 1/4 (5-End) Sateen with Move No. 3, how does the marking begin?

What is the significance of using colored boxes and blank boxes in these weave patterns?

What is the significance of using colored boxes and blank boxes in these weave patterns?

What is the process for filling the first end in a Satin/Sateen weave pattern?

What is the process for filling the first end in a Satin/Sateen weave pattern?

How do you differentiate between S-Satin and Z-Satin in a 4/1 Satin pattern?

How do you differentiate between S-Satin and Z-Satin in a 4/1 Satin pattern?

What distinguishes Regular Satin/Sateen Weave from Irregular Satin/Sateen Weave?

What distinguishes Regular Satin/Sateen Weave from Irregular Satin/Sateen Weave?

What applications are commonly associated with Satin weaves?

What applications are commonly associated with Satin weaves?

What characterizes a Regular Warp Satin?

What characterizes a Regular Warp Satin?

How is an Irregular Warp Satin defined?

How is an Irregular Warp Satin defined?

What occurs concurrently when filling the second end in the Satin/Sateen pattern?

What occurs concurrently when filling the second end in the Satin/Sateen pattern?

Explain the significance of Move #2 and Move #3 in the production of 1/4 Sateen.

Explain the significance of Move #2 and Move #3 in the production of 1/4 Sateen.

Flashcards

Twill Weave Numerator

Twill Weave Numerator

The number of weft threads a warp thread overlaps in a twill weave repeat.

Twill Weave Denominator

Twill Weave Denominator

The number of weft threads a warp thread underlaps in a twill weave repeat.

Twill Repeat

Twill Repeat

The sum of the numerator and denominator in a twill weave fraction, representing the number of weft threads in one complete pattern repeat.

Balanced Twill

Balanced Twill

Signup and view all the flashcards

Irregular Cross Twill

Irregular Cross Twill

Signup and view all the flashcards

Twill Firmness

Twill Firmness

Signup and view all the flashcards

Warp-faced Twill

Warp-faced Twill

Signup and view all the flashcards

Weft-faced Twill

Weft-faced Twill

Signup and view all the flashcards

Plain Weave

Plain Weave

Signup and view all the flashcards

Plain Weave Characteristics

Plain Weave Characteristics

Signup and view all the flashcards

Twill Weave

Twill Weave

Signup and view all the flashcards

Twill Weave Characteristics

Twill Weave Characteristics

Signup and view all the flashcards

Right-hand Twill

Right-hand Twill

Signup and view all the flashcards

Left-hand Twill

Left-hand Twill

Signup and view all the flashcards

Weave Firmness

Weave Firmness

Signup and view all the flashcards

Weave Applications

Weave Applications

Signup and view all the flashcards

Yarn Twist Direction

Yarn Twist Direction

Signup and view all the flashcards

Z Twist Yarn

Z Twist Yarn

Signup and view all the flashcards

S Twist Yarn

S Twist Yarn

Signup and view all the flashcards

Sateen Weave

Sateen Weave

Signup and view all the flashcards

Move Numbers (Satin/Sateen)

Move Numbers (Satin/Sateen)

Signup and view all the flashcards

Twill Prominence

Twill Prominence

Signup and view all the flashcards

Satin/Sateen Weave

Satin/Sateen Weave

Signup and view all the flashcards

Move Number

Move Number

Signup and view all the flashcards

Weave Repeat

Weave Repeat

Signup and view all the flashcards

Rules for Move Number

Rules for Move Number

Signup and view all the flashcards

4/1 Satin

4/1 Satin

Signup and view all the flashcards

Move number exclusion rules

Move number exclusion rules

Signup and view all the flashcards

Filling Yarn

Filling Yarn

Signup and view all the flashcards

Warp Yarn

Warp Yarn

Signup and view all the flashcards

4/1 Satin Weave

4/1 Satin Weave

Signup and view all the flashcards

Satin with Move No. 2

Satin with Move No. 2

Signup and view all the flashcards

1/4 Sateen Weave

1/4 Sateen Weave

Signup and view all the flashcards

Sateen with Move No. 2

Sateen with Move No. 2

Signup and view all the flashcards

Warp End

Warp End

Signup and view all the flashcards

Weft Insertion

Weft Insertion

Signup and view all the flashcards

1/4 Sateen with Move No. 3

1/4 Sateen with Move No. 3

Signup and view all the flashcards

Regular Satin

Regular Satin

Signup and view all the flashcards

Irregular Satin

Irregular Satin

Signup and view all the flashcards

Satin Applications

Satin Applications

Signup and view all the flashcards

Direction of Satin Diagonal Lines

Direction of Satin Diagonal Lines

Signup and view all the flashcards

Study Notes

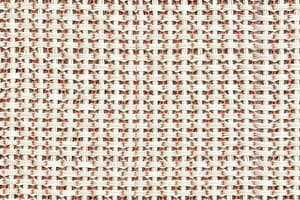

Plain Weaves

- Also known as calico or tabby weave

- Simplest weave with a repeat size of 2

- Characteristics:

- No right or wrong side

- No lengthwise or crosswise stretch

- Less absorbent than other weaves

- Easy to crease

- Doesn't fray easily

- Versatile

- Tightest weave structure

- Strong

- Durable

- Method of representation:

- Threads interlace in alternate order (first warp thread overlaps the first weft thread,and passes under the second weft thread, the second warp thread passes under the first weft thread and overlaps the second one,and so on).

- Applications:

- Shirting

- Suiting

- Outer garments

- Sheer fabrics

- Blouses

- Dresses

- Textural Stability:

- Firmness of a woven fabric depends on the frequency of interlacing between warp and weft threads.

- More intersections mean a firmer fabric.

Twill Weaves

- Second basic weave

- Distinguishing feature: pronounced diagonal lines along the fabric width

- Diagonal lines repeated regularly, usually running from left to right and right to left at a 45 degree angle.

- Twill weaves vary in their angle from a low slope to a very steep slope.

- A twill warp end must float over a minimum of two weft picks and under one weft pick; otherwise, it will still be a plain weave.

- Classification:

- Right hand twill (diagonals run from right to left, called Z-twill), left hand twill (diagonals run from left to right, called S-twill)

- Method of representation: fractions (e.g., 2/1, 3/1, 3/2) - numerator is the number of weft threads a warp thread overlaps; denominator is the number of weft threads a warp thread underlaps within the repeat, the sum of the fractions = repeat size

- Firmness: depends upon number of intersections per unit area

- Types:

- Balanced twill

- Irregular cross twill

- Applications:

- Drill cloth

- Khaki uniforms

- Denim cloth

- Blankets

- Shirting

- Hangings

- Soft furnishings

- Jeans

- Characteristics:

- Twill weaves may vary in angle

- Additional Notes:

- Variations from low slope to very steep slope are possible

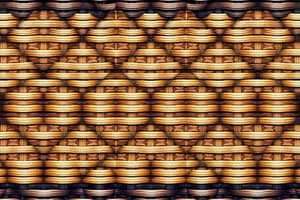

Satin and Sateen Weaves

- Satin is a warp-faced rearranged twill and Sateen is a weft-faced rearranged twill

- Warp is more prominent in Satin, and weft in Sateen

- Common use: as part of ornamented fabrics

- Striking characteristic: bright appearance and smooth feel, due to fine count filament yarns; few interlacing points, which provide long floats

- Characteristics:

- Either warp or weft faced

- No prominent weave structures

- One binding point in each end or pick

- No continuous twill lines

- Poor seam strength due to thread mobility

- Possible to have more thread density in warp and weft, and greater mass per unit area

- Having less binding points and more float lengths

- Using move numbers is necessary to construct these weaves

- Method of representation: Fractions (e.g., 4/1, 1/4) - numerator = number of weft threads a warp thread overlaps, and denominator= number of weft threads skipped by warp thread in a repeat

- Applications:

- Denim.

- Fabric interlinings.

- Ribbons.

- Dress materials (lustrous).

- Children's clothing materials.

Plain Weave Derivatives

- Warp Rib

- Weft Rib

- Matt

Twill Weave Derivatives

- Pointed Twill

- Herringbone Twill

- Combined Twill

- Broken Twill

- Elongated Twill

Honeycomb Weaves

- Threads form ridges and hollows, giving a cell-like appearance

- Warp and weft threads float freely on either fabric side

- Fabric is highly moisture absorbent

- Common uses: towels, bedcovers, quilts

- Types:

- Ordinary Honeycombs (Single Ridge, Double Ridge)

- Brighton's Honeycomb

Mockleno Weaves

- Imitation of leno or gauze weaves

- Similar perforated effects to leno or gauze weaving

- Types:

- Simple Mockleno

- Spotted Mockleno

Huckaback Weaves

- Coarse absorbent linen or cotton fabric for towels and glass cloth

- Structure: similar to a checkerboard

- Features: moisture-absorbing, firm, and hard-wearing

Diamond & Diaper Weaves

- Further development of twill weave structures

- Diamond weaves: combining right and left hand twills in four divided portions

- Diaper weaves: combining right and left hand twills using herringbone junctions

Crepe Fabrics

- Fabrics: characterized by roughness and irregularity

- Production methods:

- Using crepe yarns (hard, high twist for irregular appearance)

- Applying special finishes (e.g., chemical/mechanical shrinkage to give crinkled/abraded effect)

- Using special woven structures (e.g., combining weaves in specific ways)

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.