Podcast

Questions and Answers

What modification was made to the clutch design in the new turbo systems compared to the previous models?

What modification was made to the clutch design in the new turbo systems compared to the previous models?

How many rollers are included in the new clutch design?

How many rollers are included in the new clutch design?

What is a key characteristic of the external clutch's camplate compared to previous types?

What is a key characteristic of the external clutch's camplate compared to previous types?

What design element contributes to the improved load-carrying characteristics of the new roller clutch?

What design element contributes to the improved load-carrying characteristics of the new roller clutch?

Signup and view all the answers

In the updated design, where is the planetary ring gear positioned in relation to the clutch?

In the updated design, where is the planetary ring gear positioned in relation to the clutch?

Signup and view all the answers

What is the main function of the turbine blades in the exhaust gas flow?

What is the main function of the turbine blades in the exhaust gas flow?

Signup and view all the answers

How many blades do the 710-B models have?

How many blades do the 710-B models have?

Signup and view all the answers

Which component of the sun gear shaft acts as a part of the third air seal?

Which component of the sun gear shaft acts as a part of the third air seal?

Signup and view all the answers

What does the sun gear do in the planetary gear drive system?

What does the sun gear do in the planetary gear drive system?

Signup and view all the answers

Where are the turbocharger bearings located?

Where are the turbocharger bearings located?

Signup and view all the answers

What is the purpose of the turbine bearing journal?

What is the purpose of the turbine bearing journal?

Signup and view all the answers

What is a notable feature of the design and construction of the turbocharger bearings?

What is a notable feature of the design and construction of the turbocharger bearings?

Signup and view all the answers

What is the primary function of labyrinth seals in a turbocharger?

What is the primary function of labyrinth seals in a turbocharger?

Signup and view all the answers

Where is the impeller seal located in the turbocharger?

Where is the impeller seal located in the turbocharger?

Signup and view all the answers

What can hinder the effectiveness of labyrinth seals?

What can hinder the effectiveness of labyrinth seals?

Signup and view all the answers

How many labyrinth seals are present in the EMD turbo?

How many labyrinth seals are present in the EMD turbo?

Signup and view all the answers

What role does the compressor seal play in a turbocharger?

What role does the compressor seal play in a turbocharger?

Signup and view all the answers

What might be a consequence of reduced airflow due to dirt deposits in a turbocharger?

What might be a consequence of reduced airflow due to dirt deposits in a turbocharger?

Signup and view all the answers

Which of the following components is NOT a function of the labyrinth seals?

Which of the following components is NOT a function of the labyrinth seals?

Signup and view all the answers

What could occur if the compressor seal fails?

What could occur if the compressor seal fails?

Signup and view all the answers

What is a potential risk associated with improper air filtration in a turbocharger?

What is a potential risk associated with improper air filtration in a turbocharger?

Signup and view all the answers

What happens when the camplate is locked?

What happens when the camplate is locked?

Signup and view all the answers

Which component is directly rotated by the starter motor pinions?

Which component is directly rotated by the starter motor pinions?

Signup and view all the answers

Which gear transmits the force from the crank gear to the upper idler gear?

Which gear transmits the force from the crank gear to the upper idler gear?

Signup and view all the answers

What results from the torque input to the ring gear?

What results from the torque input to the ring gear?

Signup and view all the answers

How does torque transfer through the gear train after the camplate locks?

How does torque transfer through the gear train after the camplate locks?

Signup and view all the answers

What role does the lower idler gear play in the gear train?

What role does the lower idler gear play in the gear train?

Signup and view all the answers

What action do the rollers perform when the torque input is applied to the ring gear?

What action do the rollers perform when the torque input is applied to the ring gear?

Signup and view all the answers

What is the main function of the turbo drive gear assembly?

What is the main function of the turbo drive gear assembly?

Signup and view all the answers

What happens to the planet gears in the rotating carrier shaft?

What happens to the planet gears in the rotating carrier shaft?

Signup and view all the answers

Which gear is responsible for turning the entire carrier shaft assembly?

Which gear is responsible for turning the entire carrier shaft assembly?

Signup and view all the answers

What is the primary function of the clutch housing in the described assembly?

What is the primary function of the clutch housing in the described assembly?

Signup and view all the answers

What type of surface materials are used between the clutch support and the clutch housing?

What type of surface materials are used between the clutch support and the clutch housing?

Signup and view all the answers

How does the overrunning clutch lock up in one direction?

How does the overrunning clutch lock up in one direction?

Signup and view all the answers

What is the arrangement of the pockets in the camplate designed for?

What is the arrangement of the pockets in the camplate designed for?

Signup and view all the answers

What happens when the camplate is rotated clockwise?

What happens when the camplate is rotated clockwise?

Signup and view all the answers

How do the pocket depths in the camplate vary?

How do the pocket depths in the camplate vary?

Signup and view all the answers

What is the purpose of the angled ramps in the camplate pockets?

What is the purpose of the angled ramps in the camplate pockets?

Signup and view all the answers

Which direction of rotation causes the camplate to engage and lock up the roller?

Which direction of rotation causes the camplate to engage and lock up the roller?

Signup and view all the answers

What role do the cylindrical rollers play in the overrunning clutch mechanism?

What role do the cylindrical rollers play in the overrunning clutch mechanism?

Signup and view all the answers

What feature of the clutch camplate allows it to engage effectively?

What feature of the clutch camplate allows it to engage effectively?

Signup and view all the answers

What is the primary advantage of using a turbocharger in an engine?

What is the primary advantage of using a turbocharger in an engine?

Signup and view all the answers

At what condition does the turbocharger disconnect from the engine gear train?

At what condition does the turbocharger disconnect from the engine gear train?

Signup and view all the answers

What is the significance of the connecting gear train in a turbocharger?

What is the significance of the connecting gear train in a turbocharger?

Signup and view all the answers

What temperature does the exhaust reach to enable the turbocharger to operate without assistance from the engine?

What temperature does the exhaust reach to enable the turbocharger to operate without assistance from the engine?

Signup and view all the answers

Which of the following components is NOT mentioned as part of the turbocharger?

Which of the following components is NOT mentioned as part of the turbocharger?

Signup and view all the answers

Why is the turbocharger able to operate solely on exhaust heat under full loading conditions?

Why is the turbocharger able to operate solely on exhaust heat under full loading conditions?

Signup and view all the answers

What condition might lead the engine to drive the turbocharger rather than the exhaust gases?

What condition might lead the engine to drive the turbocharger rather than the exhaust gases?

Signup and view all the answers

What prevents the rotation of the ring gear in the described assembly?

What prevents the rotation of the ring gear in the described assembly?

Signup and view all the answers

Which of the following components is specified as NOT commonly used with the 645 type turbos?

Which of the following components is specified as NOT commonly used with the 645 type turbos?

Signup and view all the answers

What role does the engagement of the clutch support play in the turbo system?

What role does the engagement of the clutch support play in the turbo system?

Signup and view all the answers

Which feature is essential for high-capacity planetary systems in the 645 type turbos?

Which feature is essential for high-capacity planetary systems in the 645 type turbos?

Signup and view all the answers

What is a potential issue when the clutch support is fixed in place?

What is a potential issue when the clutch support is fixed in place?

Signup and view all the answers

What information does the serial number of a turbocharger provide?

What information does the serial number of a turbocharger provide?

Signup and view all the answers

Which letter designation is used for a turbocharger produced in December?

Which letter designation is used for a turbocharger produced in December?

Signup and view all the answers

How does the part number of a turbocharger convey information?

How does the part number of a turbocharger convey information?

Signup and view all the answers

What does a turbocharger's part catalog provide?

What does a turbocharger's part catalog provide?

Signup and view all the answers

When is the designation '1' used in turbocharger type indicators?

When is the designation '1' used in turbocharger type indicators?

Signup and view all the answers

Which month is represented by the letter 'C' in the turbocharger serial number?

Which month is represented by the letter 'C' in the turbocharger serial number?

Signup and view all the answers

What does the part number in a turbocharger part catalog specifically indicate?

What does the part number in a turbocharger part catalog specifically indicate?

Signup and view all the answers

Which of the following statements is NOT true about the turbocharger assembly details?

Which of the following statements is NOT true about the turbocharger assembly details?

Signup and view all the answers

In the context of turbocharger identification, what does the month component of a serial number signify?

In the context of turbocharger identification, what does the month component of a serial number signify?

Signup and view all the answers

What is the maximum tolerance for the bore through which the turbine wheel passes in the doweling assembly?

What is the maximum tolerance for the bore through which the turbine wheel passes in the doweling assembly?

Signup and view all the answers

Which component is responsible for providing a location point for the turbine wheel at the compressor-end?

Which component is responsible for providing a location point for the turbine wheel at the compressor-end?

Signup and view all the answers

What process is used to identify the matched set for the components of the doweling assembly?

What process is used to identify the matched set for the components of the doweling assembly?

Signup and view all the answers

Which part of the doweling assembly is described as forming the air scroll through which the compressor air flows?

Which part of the doweling assembly is described as forming the air scroll through which the compressor air flows?

Signup and view all the answers

When a new part is introduced to the doweling assembly, what must it receive to identify it as part of the original set?

When a new part is introduced to the doweling assembly, what must it receive to identify it as part of the original set?

Signup and view all the answers

Which component of the doweling assembly contains the planetary gear system?

Which component of the doweling assembly contains the planetary gear system?

Signup and view all the answers

What is the primary role of the doweling assembly in the turbo?

What is the primary role of the doweling assembly in the turbo?

Signup and view all the answers

Which two components make up the primary structure through which air flows in the doweling assembly?

Which two components make up the primary structure through which air flows in the doweling assembly?

Signup and view all the answers

What must be done to maintain the alignment of the components during the manufacturing of the doweling assembly?

What must be done to maintain the alignment of the components during the manufacturing of the doweling assembly?

Signup and view all the answers

Which component is central to the turbocharger's structural integrity, serving as the attachment point for others?

Which component is central to the turbocharger's structural integrity, serving as the attachment point for others?

Signup and view all the answers

What is the primary function of the turbine shroud in a turbocharger?

What is the primary function of the turbine shroud in a turbocharger?

Signup and view all the answers

Why is the blade tip to shroud clearance important in a turbocharger design?

Why is the blade tip to shroud clearance important in a turbocharger design?

Signup and view all the answers

How does the design of the turbine shroud contribute to the turbo's efficiency?

How does the design of the turbine shroud contribute to the turbo's efficiency?

Signup and view all the answers

What is a unique feature of the inside diameter of the EMD turbine shroud?

What is a unique feature of the inside diameter of the EMD turbine shroud?

Signup and view all the answers

What happens to the turbine blades as they normalize in temperature?

What happens to the turbine blades as they normalize in temperature?

Signup and view all the answers

What occurs if there is excessive clearance between the blade tips and the shroud?

What occurs if there is excessive clearance between the blade tips and the shroud?

Signup and view all the answers

What is primarily responsible for generating power in a turbocharger system?

What is primarily responsible for generating power in a turbocharger system?

Signup and view all the answers

Which aspect of the turbine shroud design is critical to the performance of a turbocharger?

Which aspect of the turbine shroud design is critical to the performance of a turbocharger?

Signup and view all the answers

What factor is important for the function of the turbine blades in relation to the shroud?

What factor is important for the function of the turbine blades in relation to the shroud?

Signup and view all the answers

What is the consequence of poor design in the clearance between the shroud and blades?

What is the consequence of poor design in the clearance between the shroud and blades?

Signup and view all the answers

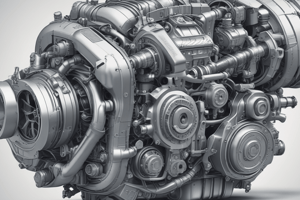

Study Notes

Air Intake & Exhaust Systems

- Turbochargers are primarily used to increase engine horsepower and fuel economy by utilizing exhaust gases

- The connecting gear train is needed for starting, light load, and quick acceleration because there isn't enough exhaust heat energy otherwise

- When the engine is at full load, the exhaust gas heat (approaching 1000°F/538°C) is sufficient to power the turbocharger without external drive

- An overrunning clutch disengages the turbocharger from the engine during full load operation

Turbocharger Nameplate

- The nameplate includes the model number, serial number, and identification code

- The part number specifically indicates the type of turbo, such as a 16-cylinder marine turbo

Serial Number

- The serial number contains date, production sequence number, and assembly location of the turbo

- Example: 88-A1-1005 (Year 1988, Month January, Type New, Plant LaGrange, Sequence 5)

- The last three digits indicate the build sequence at a particular plant each month

Doweling Assembly

- The assembly is comprised of 6 iron castings, which are aligned and held together with dowels and threaded fasteners

- The alignment is critical for precise functionality

- Dowelling numbers are stamped to identify matched component sets for repairs

Turbine Wheel

- The turbine wheel is the heart of the turbocharger, involving a shaft, turbine blades, and an impeller

- The shaft is supported by two bearings (compressor bearing and turbine bearing)

- The assembly needs careful balancing to minimize vibrations during high rotational speeds

Turbocharger Bearings

- The compressor and turbine bearings in turbochargers use cylindrical tapers to create oil wedges and center the rotating parts

- Oil ramps within the bearings increase centering force during rotation due to decreasing clearance

- The ramps start at an oil channel or groove

Main Housing "Cradle" Gasket Area

- The gasket area between the main housing and compressor bearing support was changed to an oval-shaped oil passage with O-rings for improved sealing

- Older castings with oval openings use the Parker Seal with o-rings on each side of a metal plate for improved sealing

Turbine Wheel

- The turbine wheel, or rotating assembly, is comprised of a shaft with both the turbine blades (exhaust fan) and the impeller (air compressor fan)

- The shaft is supported by two bearings—the compressor bearing and turbine bearing

- A gear on the turbine end connects to the engine crankshaft, and various other gears complete the drive train

Turbocharger Bearings

- The bearings are designed with cylindrical tapers to create hydraulic forces for centering the rotating journals

- Oil ramps within the bearings generate forces which increase with rotor speed

- Up to 5 ramps are typically used, and they begin at an oil channel or groove

Turbine Inlet Scroll & Nozzle Ring

- The exhaust inlet scroll smoothly directs high-energy exhaust gas to the turbine for efficient power generation

- The nozzle ring is a set of stationary vanes in the exhaust portion of the turbine section

- These vanes direct the exhaust gas flow to the turbine blades to maximize power output

- The nozzle ring size is matched to the engine's exhaust flow to optimize operation

Turbine Shroud & Retaining Clamp

- The turbine shroud is a metal band around the turbine blades, minimizing gas leakage and maximizing gas flow across the blades

- The shroud is retained by a Marmon Clamp, which has 4 channel segments spot-welded to the band

Exhaust Diffuser

- The exhaust diffuser, consisting of 3-4 vanes, directs exhaust flow from the turbine blades to the exhaust duct

- This smooths the gas flow and minimizes turbulence

Exhaust Duct

- The exhaust duct serves as the outlet for the engine's exhaust gases after passing through the turbine blades

- It is bolted to the main housing with spring washers allowing thermal expansion

- Two basic types exist: standard and big-foot, with different mounting configurations for variations in applications.

Oil Drain Opening

- A drain opening near the exhaust duct bottom allows for drainage of rainwater during engine shutdown

- A smaller drain tube connected to the opening in the compressor bearing support prevents exhaust gases from leaking

Compressor Diffuser

- The compressor diffuser consists of fins mounted around the circumference of the impeller

- The fins direct the compressed air discharged from the impeller, ensuring a smooth and turbulence-free air flow

- The throat passage size of the diffuser is matched to the turbine nozzle ring for optimal turbo operation during full load

Planet Gears

- The sun gear on the turbine wheel engages with three planet gears at 120-degree intervals

- The planet gears are located by a planetary carrier shaft

- These gears transfer torque to the turbine wheel at a higher rotational speed than the carrier shaft

Ring Gear and Clutch Housing

- The ring gear surrounds the three planet gears, having internally cut teeth on its inside diameter

- The ring gear is attached to a housing that encloses the turbo clutch through bolts.

Clutch Camplate and Rollers

- The overrunning clutch design allows rotation in one direction, enabling "lock-up" in the other

- This design utilizes a support, rollers, and a camplate with pockets, allowing the rollers to engage or disengage

Gear Drive System

- The splined-end of the carrier shaft extends through the idler gear support

- The shaft is supported by two bearings: a ball bearing in the idler support and a roller bearing in the carrier support

- A drive gear is mounted on the shaft's splines and connects to the engine gear train

Right-Hand Drive Applications

- Some applications use a pair of counter-rotating engines, with the right-hand rotation engine using a different turbo for rotational direction matching

Lube Oil System

- The turbocharger's lubrication system is an extension of the engine oil system

- Oil flows to the turbo through passages in the crankshaft, entering the lubricating manifold and then to the oil filters

Soak-Back System

- A soak-back oiling system maintains lubrication for the engine at periods when the standard main oil system is not supplying sufficient lubrication

- The soak-back pump electrically supplies oil for 30-35 minutes after engine shutdown for maintaining bearings and seals

Planetary System Oil Drainage Screen

- The screen in the idler gear support prevents foreign objects from entering the engine oil sump or passing into the rear gear train

- Designed for use with high-capacity planet gears, the screen has three slotted passages along the support surface to ensure sufficient oil drainage

Gear Train Operation

- The EMD turbocharger uses a geardrive system, taking energy from the crankshaft and transmitting it to the turbine wheel.

- The system helps ensure sufficient power for engine starting and low-speed/light load conditions

Turbochargers with External Clutch

- The external clutch design removes the clutch from the turbo and mounts it in the engine camshaft drive gear train

- The clutch design uses 16 three-quarter-inch diameter rollers compared to the internal clutch's 12 one-half-inch rollers

Foreign Material Damage

- Mechanical break-up of any power assembly component can damage the turbine nozzle ring and turbine blades due to foreign material, including broken piston rings and exhaust valve fragments, which can enter the turbo

Clutch Failure

- Clutch failures can occur due to abnormal vibration, worn planetary gears, frequent abnormal cycling, and contaminated lubricants

Lack of Proper Lubrication

- Failure due to a lubrication system malfunction, including soakback pump failure, lube oil pump failure, blocked passages, or contaminated oil, can lead to lubrication issues

Turbine Blade Fatigue Fracture

- Fractures can be caused by foreign material introduction, causing vibrations. High frequency vibrations from poor planetary gear mesh, manufacturing defects, or material fatigue, can lead to blade failures.

Poor Planetary Gear Train Mesh

- Eroded planet bearings, fatigue fractures of turbine blades, or broken planet gears or sun gears can cause damage in the planetary gear train

External Gear Damage

- Damage to the externally mounted gears on the back side of the turbo can signal problems with the engine's gear train, rather than the turbo.

Turbocharger Installation Tips

- Inspect engine exhaust manifold, screens, engine gear train and air filters for any problems

- Replace engine filters, aftercoolers, and oil drain pans if necessary.

- Check valve timing

Screen Inspection Port

- The screen assembly is located between the turbo and the rear manifold to prevent foreign material ingress

- Periodic inspection is mandated to check for screen damage or plugging

Exhaust System Data

- Provides data on various engine models and their respective turbine inlet temperatures, exhaust CFM, and air box pressures

- Shows variations between different model turbochagers

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

Explore the fundamental concepts of air intake and exhaust systems, focusing on turbochargers. Learn how turbochargers enhance engine performance by utilizing exhaust gases and their critical components like nameplates and serial numbers. This quiz will test your understanding of the practical applications and technical specifications of these systems.