Podcast

Questions and Answers

What is a primary limitation of sterilizers based on downward displacement of air?

What is a primary limitation of sterilizers based on downward displacement of air?

- They are not effective for porous and hollow loads. (correct)

- They are only suitable for gaseous substances.

- They consume an excessive amount of energy.

- They are much smaller than vacuum sterilizers.

Why should a package with a wet exterior or contents not be considered sterile?

Why should a package with a wet exterior or contents not be considered sterile?

- Because wet materials can easily re-contaminate. (correct)

- Because wet packages lead to improper handling.

- Because it takes longer to dry.

- Because it indicates a possible vacuum failure.

Which method is suggested for improved air removal and drying in sterilization of porous and hollow loads?

Which method is suggested for improved air removal and drying in sterilization of porous and hollow loads?

- Using a chemical sterilant.

- Increasing the temperature of the autoclave.

- Using a vacuum pump before and after sterilization. (correct)

- Extending the duration of the steam exposure.

According to ISO and CEN standards, what types of items are suitable for sterilization using downward displacement?

According to ISO and CEN standards, what types of items are suitable for sterilization using downward displacement?

What effect does the condensation of steam have on the load during sterilization using downward displacement?

What effect does the condensation of steam have on the load during sterilization using downward displacement?

What is the primary advantage of using a vacuum pump before the sterilization process?

What is the primary advantage of using a vacuum pump before the sterilization process?

What problem arises when steam condenses inside a textile material during sterilization?

What problem arises when steam condenses inside a textile material during sterilization?

What additional measure is essential when allowing air back into the autoclave after sterilization?

What additional measure is essential when allowing air back into the autoclave after sterilization?

What is the first step in a complete sterilization process with single pre-vacuum?

What is the first step in a complete sterilization process with single pre-vacuum?

What type of pump is driven by a fluid or gas stream?

What type of pump is driven by a fluid or gas stream?

What is required in large quantities for the operation of a water jet pump?

What is required in large quantities for the operation of a water jet pump?

Why is a deep pre-vacuum process not suitable for cotton textiles?

Why is a deep pre-vacuum process not suitable for cotton textiles?

Which component causes the creation of suction in the water ring pump?

Which component causes the creation of suction in the water ring pump?

What is used to improve air removal during the pre-vacuum phase in a steam injection sterilization process?

What is used to improve air removal during the pre-vacuum phase in a steam injection sterilization process?

Where is the air expelled in a water ring pump?

Where is the air expelled in a water ring pump?

Which sterilization process is effective only with small steam sterilizers?

Which sterilization process is effective only with small steam sterilizers?

What happens as a result of the low pressure in the water ring pump?

What happens as a result of the low pressure in the water ring pump?

Which materials is the above-atmospheric steam pulses sterilization method suitable for?

Which materials is the above-atmospheric steam pulses sterilization method suitable for?

What must follow steam pulses for long lumens in the above-atmospheric steam pulses process?

What must follow steam pulses for long lumens in the above-atmospheric steam pulses process?

What is used to prevent cavitation in a water ring pump?

What is used to prevent cavitation in a water ring pump?

What determines the depth of the vacuum that can be achieved in a water ring pump?

What determines the depth of the vacuum that can be achieved in a water ring pump?

Which sterilization process is considered the safest for materials where air can be trapped?

Which sterilization process is considered the safest for materials where air can be trapped?

During which phase does the chamber get larger in the water ring pump?

During which phase does the chamber get larger in the water ring pump?

What happens after each cycle in the fractional pre-vacuum process?

What happens after each cycle in the fractional pre-vacuum process?

What is one of the benefits of slowly increasing the temperature before the sterilization phase?

What is one of the benefits of slowly increasing the temperature before the sterilization phase?

What is a disadvantage of pulsating dry filtered air during vacuum drying?

What is a disadvantage of pulsating dry filtered air during vacuum drying?

What is a critical phase in the sterilization process in steam sterilizers?

What is a critical phase in the sterilization process in steam sterilizers?

In an autoclave with a vacuum system, what must be done with the condensate?

In an autoclave with a vacuum system, what must be done with the condensate?

How does a condensate pot function in an autoclave?

How does a condensate pot function in an autoclave?

What is one advantage of an autoclave with a jacketed chamber during drying?

What is one advantage of an autoclave with a jacketed chamber during drying?

What component connects the steam generator and sterilization chamber in an autoclave with a vacuum system?

What component connects the steam generator and sterilization chamber in an autoclave with a vacuum system?

What is one function of the jacketed chamber in modern autoclaves?

What is one function of the jacketed chamber in modern autoclaves?

What type of chamber is commonly found in modern autoclaves on the CSA?

What type of chamber is commonly found in modern autoclaves on the CSA?

Which system helps reduce the chance of recontamination in an autoclaaf?

Which system helps reduce the chance of recontamination in an autoclaaf?

Why is a mantle (mantelautoclaaf) important in an autoclave?

Why is a mantle (mantelautoclaaf) important in an autoclave?

What creates the vacuum in a modern autoclave?

What creates the vacuum in a modern autoclave?

Which of the following tasks must be done manually by the operator in a manually operated autoclave?

Which of the following tasks must be done manually by the operator in a manually operated autoclave?

What does an automatic process control ensure in an autocalve?

What does an automatic process control ensure in an autocalve?

Which component is NOT required in an automatically controlled autoclave?

Which component is NOT required in an automatically controlled autoclave?

Which task is NOT required by the operator in an automatic autoclave?

Which task is NOT required by the operator in an automatic autoclave?

Flashcards are hidden until you start studying

Study Notes

Sterilization Methods

- Autoclaves in this chapter are based on downward air displacement, but this method is not able to remove all air from porous loads and hollow instruments.

- Air removal is a critical phase in the sterilization process, especially for hollow instruments and porous loads.

Drawbacks of Simple Sterilizers

- The process of downward air displacement is not sufficient for porous and hollow loads.

- It takes a long time to bring the entire load into contact with steam, resulting in a longer sterilization time.

- The loading method strongly influences air removal.

- Steam condenses on the load, leaving it wet without further measures.

Sterilization of Hollow Instruments and Porous Loads

- Hollow instruments and porous loads (such as textiles) are difficult to sterilize because they contain a lot of air.

- This air can become trapped when steam enters the package from different sides.

- Condensation during sterilization can also lead to trapped condensate, causing materials to remain wet and potentially re-contaminated.

Vacuum in Sterilization

- Using vacuum before and after sterilization can help overcome these problems.

- A vacuum pump removes air from the chamber before sterilization, allowing steam to penetrate the load more easily.

- After sterilization, a vacuum helps to remove condensate and dry the load.

Basic Sterilization Process

- The basic steps of a sterilization process with a single vacuum phase are:

- Air removal by vacuum

- Heating and pressure build-up

- Sterilization

- Steam release

- Drying by vacuum

- Allowing air to enter the chamber

Sterilization Process with Deep Vacuum

- A single vacuum phase may not be enough to remove all air from the smallest pores of porous loads.

- Using a stronger vacuum pump can create a deeper and longer vacuum phase, but this may still not be sufficient.

- Multiple steam pulses may be necessary for adequate air removal.

Sterilization Process with Steam Injection

- To improve air removal during the vacuum phase, a small amount of steam can be injected into the chamber.

- The steam displaces air, allowing for more efficient air removal.

- A continuous steam flow can also be used during the pressure build-up and sterilization phases.

Sterilization Process with Bov-atmospheric Steam Pulses

- Using multiple steam pulses at above-atmospheric pressure can help to remove air from the load more effectively.

- This method is suitable for textile packets and hollow instruments, but may require a vacuum phase for longer lumens.

Sterilization Process with Fractionated Vacuum

- Combining a vacuum phase with steam pulses can create an optimal sterilization process.

- This process involves alternating between vacuum and steam pulses to remove air from the load.

Vacuum Pumps

- Two types of pumps are used to create a vacuum:

- Ejector (jet pump)

- Ring pump (rotary pump)

Ejector (Jet Pump)

- An ejector is a pump that uses a fluid or gas stream to drive the pump.

- It works by using the flow energy of the stream to move other fluids or gases.

- A steam ejector pump can use the same steam as the sterilization process, requiring less water.

Ring Pump (Rotary Pump)

- A ring pump is driven by an electric motor and uses centrifugal force to create a vacuum.

- It has two openings: an inlet port and an outlet port.

- The inlet port is where the chamber expands, creating a vacuum, and the outlet port is where the chamber contracts, creating compression.

Cooling Water

- The steam that is sucked into the ring pump can cause the water to heat up, affecting the pump's performance.

- To prevent this, the pump must be cooled, and the temperature of the cooling water affects the depth of the vacuum.

Cavitiation

- Cavitiation occurs when the water in the ring pump boils due to the low pressure.

- A way to prevent cavitiation is to use a condenser, which cools the steam before it enters the pump.

Improving Drying

- Several methods can be used to improve the drying of especially "black" packets:

- Gradually increasing the temperature before the sterilization phase

- Pulsing dry filtered air or overheated steam during the vacuum phase

- Using a condenser to cool the steam before it enters the pump

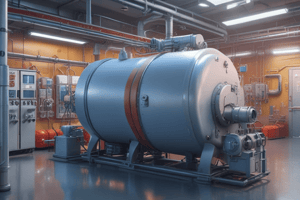

Autoclave Design

- A basic autoclave design involves a separate steam generator and sterilization chamber.

- The chamber is connected to the steam generator via a pipeline, and a valve is used to control the flow.

- The steam generator and sterilization chamber are separated to prevent condensate from entering the pipeline.

Advantages of an Autoclave with a Jacketed Chamber

- The chamber wall is warm when the steam enters, reducing the amount of condensate and resulting in drier loads.

- The warming-up time can be shorter, reducing the overall process time.

- The hot chamber wall helps to keep the load warm during the drying phase, improving drying.

- The temperature distribution in the chamber is more even, resulting in a more reproducible sterilization process.

CSA Autoclave Design

- Most modern autoclaves on the CSA (Central Sterilization Area) are built according to a basic plan:

- Horizontal chamber for easier loading and unloading

- Two-door system to reduce the risk of re-contamination

- Jacketed chamber to improve drying and temperature distribution

- Vacuum creation using a ring pump

- Separate steam generator or central steam supply

- Fully automatic process control to ensure reproducibility and adherence to guidelines

Process Control

- To manually operate an autoclave, the operator must:

- Have knowledge of the processes

- Take measurements of pressure and temperature

- Make decisions about which valves and switches to operate

- Operate the valves and switches manually

- Manual process control is not 100% reproducible and may not meet international standards.

- Automatic process control is necessary to meet these standards, requiring the operator to:

- Load the autoclave correctly

- Select the correct program and start it

- Unload the autoclave

- An automatically controlled sterilizer will:

- Have knowledge of each process

- Take measurements of pressure and temperature

- Make decisions about valve and switch operation

- Operate the valves and switches automatically

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.