Podcast

Questions and Answers

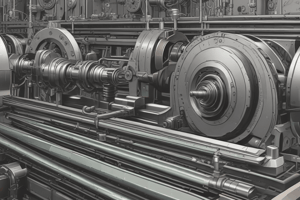

Which component of a lathe houses the driving pulleys, back gears, and spindle?

Which component of a lathe houses the driving pulleys, back gears, and spindle?

- Carriage

- Head stock (correct)

- Tail stock

- Bed

A steel shaft with a diameter of 25 mm is being machined at a cutting speed of 50 meters per minute. What is the approximate RPM of the shaft?

A steel shaft with a diameter of 25 mm is being machined at a cutting speed of 50 meters per minute. What is the approximate RPM of the shaft?

- 795.77 RPM

- 500.00 RPM

- 636.73 RPM (correct)

- 318.36 RPM

What material is commonly used in the manufacturing of lathe beds due to its vibration-dampening properties?

What material is commonly used in the manufacturing of lathe beds due to its vibration-dampening properties?

- Cast Iron (correct)

- High Alloy Steel

- High Carbon Steel

- Mild Steel

Which lathe component, positioned atop the cross slide, provides support for the tool post and cutting tool?

Which lathe component, positioned atop the cross slide, provides support for the tool post and cutting tool?

Which factors are primarily used to define the capacity or size of a lathe?

Which factors are primarily used to define the capacity or size of a lathe?

Which part of the lathe is responsible for controlling the horizontal feed movement of the cutting tool?

Which part of the lathe is responsible for controlling the horizontal feed movement of the cutting tool?

Which lathe operation does NOT primarily involve straight-line motion of the cutting tool?

Which lathe operation does NOT primarily involve straight-line motion of the cutting tool?

During threading operations on a lathe, which component is responsible for automatically moving the carriage to create the threads?

During threading operations on a lathe, which component is responsible for automatically moving the carriage to create the threads?

In the context of lathe operations, what best describes the function of a lathe mandrel?

In the context of lathe operations, what best describes the function of a lathe mandrel?

What is the primary impact of using various accessories on a lathe?

What is the primary impact of using various accessories on a lathe?

Flashcards

Head Stock

Head Stock

The housing for driving pulleys, back gear, spindle, chuck, and gear assembly in a lathe.

RPM Calculation

RPM Calculation

The formula to calculate RPM (N) given cutting speed (V) and diameter (D) in a lathe: N = (V * 1000) / (π * D).

Lathe Bed Composition

Lathe Bed Composition

Lathe beds are made of this material due to its vibration-absorbing properties.

Compound Rest

Compound Rest

Signup and view all the flashcards

Lathe Capacity

Lathe Capacity

Signup and view all the flashcards

Apron

Apron

Signup and view all the flashcards

Contour turning

Contour turning

Signup and view all the flashcards

Lead Screw

Lead Screw

Signup and view all the flashcards

Lathe Mandrel

Lathe Mandrel

Signup and view all the flashcards

Lathe Accessories

Lathe Accessories

Signup and view all the flashcards

Study Notes

- This text introduces a series of lectures that will cover the technical aspects of the RRB (Railway Recruitment Board) JE (Junior Engineer) exam, specifically using the Youth Competition Times' book containing previous years' questions.

- The speaker guarantees a proper solution to every book question.

Subjects Covered So Far

- Engineering Mechanics

- Strength of Materials

- Material Science

Current Subject Focus: Production Engineering

- Production is especially important in the context of the RRB JE exam due to its high weightage

- 2019 RRB JE exam sets have already been reviewed

- In some sets, Production Engineering accounted for as many as 15-20 questions out of 100 total questions

Chapter Starting Today: Machining

- The first chapter will cover Machining, with an emphasis on lathes, their functions, and their types

Question 1: Lathe Parts and Function

- The first question asks which part of a lathe serves as the housing for driving pulleys and back gears

- Four options were given: carriage, bed, tail stock, head stock.

- Answer: The head stock serves as the housing

Head Stock in Detail

- The head stock is the correct housing for both the driving pulleys and the back gear

- The Spindle is a key component of the head stock

- The chuck, which fits onto the spindle, is also part of the head stock

- The head stock also contains the gear assembly

- Driving pulley, back gear and switches are found in head stock

Other Lathe Components Discussed

- Tail stock

- Tool post

- Compound rest

- Saddle

- Lead screw

Question 2: Calculating RPM of a Steel Shaft

- The second question involves calculating the RPM of a steel shaft, given its diameter (25 mm) and cutting speed (50 meters per minute).

- Formula to use is

V = πDN/1000, where:V= cutting speed (m/min)D= diameter (mm)N= RPM

- Because the diameter is in mm, the formula includes dividing by 1000 to convert it to meters

- Therefore

N = (V * 1000) / (π * D) - Inserting the given values:

N = (50 * 1000) / (π * 25) ≈ 636.73 RPM - Answer: 636.73 RPM

Key Unit Considerations for Velocity Calculations

- 1st Velocity Formula:

V = πDN / 60(where D is in meters, N is in RPM, and V is in meters per second) - 2nd Velocity Formula:

V = πDN / 1000(where D is in mm, N is in RPM, and V is in meters per minute) - Remember to adjust the formula based on the units given in the question

Question 3: Composition of a Lathe Bed

- The options provided are High Carbon Steel, High Alloy Steel, Mild Steel, and Cast Iron

- Answer: Lathe beds are made of Cast Iron

- More specifically, they are made of Gray Cast Iron

- Grey Cast Iron contains 2.50 to 3.75% carbon

Advantages of Using Gray Cast Iron for Lathe Beds

- The high carbon content causes carbon to surface in the form of graphite flakes

- These graphite flakes help absorb vibrations during machine operation

Alternate Materials and Their Uses

- Mild steel is used for screws and nuts

- High carbon steel is used for files and hammers

- Medium carbon steel is used for connecting rods in internal combustion engines

Carbon Percentage in Different Types of Steel

- Low Carbon Steel: Less than 0.3% carbon

- Medium Carbon Steel: 0.3% to 0.7% carbon

- High Carbon Steel: 0.7% to 1.5% carbon

Carbon Percentage in Cast Iron

- Cast Iron: Typically 2% to 6.67% carbon

- Cast iron is made from pig iron

- Pig Iron: Contains approximately 4% carbon

Question 4: Component to Support Tools

- The question asks what component, fitted on top of the cross slide, is used to support the tool post and cutting tool

- Options are carriage, tailstock, compound rest, or saddle

- Answer: The compound rest

Components of Lathe

- Head stock

- Tail stock

- Includes "dead center" here

- Tool post

- Compound Slide

- Cross Slide

- Saddle

Question 5: Expressing Lathe Capacity

- Asks which of the given options best represent the capacity of a lathe, of the four options given the correct answer is:

- Answer: Swing and distance between centers

- Bed length also contributes in defining capacity, but this was not an option

Question 6: Controlling Horizontal Feed

- Asks which part of lathe controls horizontal feed:

- Possible answers: cross slide, apron, tail stock, head stock

- Answer: Apron

- Apron contains levers, clutches, and gears

Question 7: Feed Direction in Lathe

- Asks what operation does not involve a straight line motion:

- Answers: form turning, counter turning, contour turning, facing, taper turning

- Answer: Contour turning

- Taper turning uses straight lines to move in the direction

- While the curvature of profile is being moved, that is still done with linear motion in some direction

- Contour turning follows the profile of the part

Question 8: Moving Carriages During threading

- The question is about which part moves the carriage automatically during threading

- Options: lead screw, hand wheel, bed, feed rod

- Answer: Lead screw

- The screw threads are typically Acme threads with a 29 degree

Additional Notes on Threads

- Tumbler gears are also used in lathes

Question 9: Lathe Mandrel Function

- Asks what a lathe mandrel can be described as

- Answers given: template, gauge, fixture, jig

- Answer: Fixture

- Mandrels as well as Jigs and fixtures are all holding devices

- Mandrels are lathe accessories which hold the workpiece

- Mandrels (hollow holding devices) are similar to Fixtures during operation

Jigs vs. Fixtures

- Jigs guide the tool, while fixtures don't

Question 10: Lathe Accessories Impact

- Explores the effect of lathe accessories

- Answer: Accessories improve versatility

- Accessories such as chucks enable many operation

Examples of Lathe Accessories

- Chucks (3-jaw, 4-jaw)

- Angle plates

- Centers (dead and live centers, mentioned in reference to the tail stock)

Question 11: Center Punch Angle

- The question is about the point angle of a punch

- Possible answers: 90 degrees, other options were not specified

- Answer: Center punch

Additional Punch Types and Angles

- Prick punch: 30 degrees

- Dot punch: 60 degrees

Question 12: Standard Drill Angle

- The question is about the standard angle for a drill

- Answer: 118 degrees

- 118-degree drill is used for ductile (tensile) materials

- 135-degree drills are used for brittle materials

Question 13: Lathe Center Angle

- Angle is needed to make adjustments

- Most lathe centers are 60 degrees

Question 14: Back Gearing in a Lathe

- Asks about purpose for back gearing:

- Possible answers relating to achieving low/high speed

- Answer: Back gearing allows obtaining many speeds with low magnitude

Question 15: Controlling Apron Moments

- Asks what part of the apron controls movements:

- Answer: Carriage

- Apron is made from cast iron

Question 16: Lathe Operation With Straight Paths

- Asks what operation does not involve straight path motion

- Answer: Contour Turning

Question 17: What is used to move the Carriage Automatically

- Answer: Led Screw

Question 18: Lathe Spindle Accessories

- Also called tool accessory

- They help ensure it useful

- Helps increase accuracy and efficiency

Question 19: Point Angle Of...

- Prick punch 30 degrees

- Center punch 90 degrees

- Common question and should be studied

Question 20: Standard Drill Angle

- Point of standard drill

- 118 degrees

Question 21: Included Angle of Center

- Center

- 60 degrees

Question 22: Back Gearing Arrangement

- Is provided because;

- To obtain the low speed which are lower in magnitude

Question 23: Machine With Apron On

- Controls

- Carriage

Question 24: Machine Where Wheel Is Fed

- A straight pass

- Answer: Contour turning

Question 25: How Is The Carriage Controlled?

- Automatically while threading

- By the leadscrew

Question 26: What Can Lathe Mandrel Be Terms As?

- Termed As;

- Fixture

Question 27: Lathe Accessories Does What?

- Improve the versatility, do more work

- To support tooling

Question 28: Angle of Punch Degree?

- Prick punch 30

- Center Punch 90

- And other punches

Question 29: Ground drill angle

- Standard point:

- 118 degrees

Question 30: Angle of Lathe Included..

- The angle is;

- 60 degrees

Question 31: Gearing Arrengement

- Is for;

- More number Of Speed

Question 32: Apron...

- Is to do;

- Controll the movement of carriage

Question 33: Usually Maid Of?

- What is the late best maidd of?

- Cast Iron

Question 34: No Lubricant Needed?

- In thred cutting steel:

- Cast Iron

Question 35: Not Part Of Mechanical Press

- Which follows

- Civil Table

Question 36: Align Cutting Tool Gauge?

- With work

- Center gauge

Question 37: Given This How Much Time?

- How to give Time

- Time = Volume/Speed

Question 38: General Purpose Follows What?

- It follows

- Geometric Progression

Question 39: Serve Purpose Follow..

- Dead center.. and can support the work that

- Tailstock

Question 40: Method Of Start Thread Is Cut?

- By the multi start thred

- This leads to single point tool.

Question 41: Not On Tool

- Called as :

- Body Clear

Question 42: Machine Of Threading Is Defined!

- Cutting halical Groovers

Question 43: Speed Is Called :

- A cuttting Speed Is Called:

- Feed

Question 44: Number Of Gaze and Chucks

- Piza Chuck 3 gaze system to Self Centered

Question 45: Collate Is Can Be Called As?

- Self Centering Chuck

Question 46: Spindel Tool What?

- Tools Room and Spindel

- What Direct

Question 47:

- NOT done on work held between centers?

- Parting Off

Question 48: Increasing Cutter Tool?

- For cutting steel:

- Diamond

Question 49: Is NOT Work Holding Device!

- For Lathes device not?

- Tool post

Question 50:

Question 51::

- Not Done of Held

- Parting Off

Question 52:

- Standard Grind Is

- 118

Question 53: Control of What?

- Movement Of a What?

- Carriage

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.