Podcast

Questions and Answers

What is the main advantage of using a CNC lathe compared to an automatic lathe?

What is the main advantage of using a CNC lathe compared to an automatic lathe?

- Higher precision and accuracy (correct)

- Faster speed and feeds adjustments

- Manual control over operations

- Suitability for small-scale production

Which lathe operation involves metal removal from a cylindrical job?

Which lathe operation involves metal removal from a cylindrical job?

- Plain turning (correct)

- Step turning

- Facing

- Thread cutting

What is the purpose of knurling in lathe operations?

What is the purpose of knurling in lathe operations?

- To cut threads into the workpiece

- To remove metal from the workpiece

- To produce a textured gripping surface (correct)

- To create a tapered surface

Which component of the lathe is responsible for feeding the cutting tool perpendicular to the axis of the workpiece?

Which component of the lathe is responsible for feeding the cutting tool perpendicular to the axis of the workpiece?

What type of production work is a CNC lathe primarily used for?

What type of production work is a CNC lathe primarily used for?

In which lathe operation is the workpiece supported between two centers causing its rotation?

In which lathe operation is the workpiece supported between two centers causing its rotation?

Which type of lathe is designed for mass production work?

Which type of lathe is designed for mass production work?

Which lathe is built with a wide range of spindle speeds for precision work?

Which lathe is built with a wide range of spindle speeds for precision work?

Which lathe is primarily used for machining work requiring high accuracy?

Which lathe is primarily used for machining work requiring high accuracy?

Which lathe can perform multiple operations on a workpiece without resetting the tools?

Which lathe can perform multiple operations on a workpiece without resetting the tools?

Which lathe is designed for complete automatic control and high-speed operation?

Which lathe is designed for complete automatic control and high-speed operation?

Which lathe has a robust construction and additional mechanisms for driving the lathe spindle at multiple speeds?

Which lathe has a robust construction and additional mechanisms for driving the lathe spindle at multiple speeds?

What is the primary function of the bed in a lathe?

What is the primary function of the bed in a lathe?

What is the purpose of the V-shaped cutting tool in a lathe?

What is the purpose of the V-shaped cutting tool in a lathe?

Where is the headstock of a lathe typically located?

Where is the headstock of a lathe typically located?

What is the main spindle of a lathe driven at?

What is the main spindle of a lathe driven at?

What is the function of the tailstock in a lathe?

What is the function of the tailstock in a lathe?

What is the direction of rotation of the workpiece in a lathe?

What is the direction of rotation of the workpiece in a lathe?

Flashcards

CNC Lathe

CNC Lathe

A CNC lathe improves upon the automatic lathe by integrating a computer interface to control operations.

Plain Turning

Plain Turning

Removing metal from a cylindrical workpiece to create a straight surface.

Engine Lathe

Engine Lathe

A lathe with basic parts, robust headstock, and mechanisms for variable spindle speeds and tool feed control.

Capstan and Turret Lathe

Capstan and Turret Lathe

Signup and view all the flashcards

Tool Room Lathe

Tool Room Lathe

Signup and view all the flashcards

Automatic Lathe

Automatic Lathe

Signup and view all the flashcards

Lathe Principle

Lathe Principle

Signup and view all the flashcards

Lathe Bed

Lathe Bed

Signup and view all the flashcards

Lathe Headstock

Lathe Headstock

Signup and view all the flashcards

Lathe Tailstock

Lathe Tailstock

Signup and view all the flashcards

Turning

Turning

Signup and view all the flashcards

Step Turning

Step Turning

Signup and view all the flashcards

Facing

Facing

Signup and view all the flashcards

Taper Turning

Taper Turning

Signup and view all the flashcards

Thread Cutting

Thread Cutting

Signup and view all the flashcards

Knurling

Knurling

Signup and view all the flashcards

Chamfering

Chamfering

Signup and view all the flashcards

Study Notes

CNC Lathe

- A CNC lathe is an improvement over an automatic lathe by incorporating a computer interface.

- It uses a dedicated stored program to carry out different operations.

- High degree of precision and accuracy can be achieved by carrying out different operations on a workpiece.

- The program can be suitably changed to meet the versatile requirements.

- It is used for mass production work.

Lathe Operations

- All most all the basic machining operations can be performed on a lathe.

- Some of the important and generally performed lathe operations are:

- Turning

- Step Turning

- Facing

- Taper turning

- Thread cutting

- Knurling

- Chamfering

Turning or Plain Turning

- The process of metal removal from a cylindrical job is called straight or plain turning.

- The plain turning operation is performed using the cross slide and the carriage.

- The workpiece is supported between the two centres which cause the rotation of the workpiece.

- A single point cutting tool is fed perpendicular to the axis of the workpiece with the required depth of cut using the cross slide hand wheel and is moved parallel to the axis of the workpiece towards the headstock using the carriage hand wheel facilitating the metal removal.

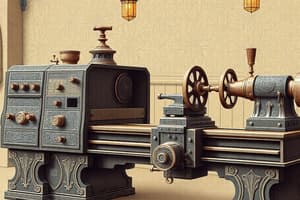

Types of Lathes

- Engine Lathe:

- It has all the basic parts and the headstock is much more robust in construction.

- It has additional mechanisms for driving the lathe spindle at multiple speeds.

- It can feed the cutting tool both in cross and longitudinal directions with reference to the lathe axis with the help of carriage, feed rod and lead screw.

- Capstan and Turret Lathe:

- It is an development over an engine lathe and is used for mass production work.

- The tailstock is replaced by a hexagonal turret on the face of which multiple tools can be fitted and fed into the work in proper sequence.

- Several different type of operations can be performed on a workpiece without resetting the work or the tools.

- Tool Room Lathe:

- A tool room lathe has features similar to an engine lathe but is more accurately built and has wide range of spindle speeds ranging from very low to high speeds.

- It is mainly used for precision work on tools, dies, gauges and in machining work where accuracy is needed.

- Automatic Lathe:

- These are high speed, heavy duty, mass production lathes with complete automatic control.

- Once the tools are set they automatically perform all the operations to finish the job.

Principle of Working of a Lathe

- The work piece is held rigidly using one of the work holding devices, known as chuck and is rotated at high speeds in an anticlockwise direction when viewed from the tailstock end or the right side end.

- A V - shaped cutting tool which is stronger and harder than the work piece is held against the workpiece and is fed or moved parallel to the lathe axis towards the headstock end or the left side end leading to the production of a cylindrical surface.

Major Parts of a Lathe and their Functions

- Bed:

- The bed is a foundation part of a lathe and supports all its other parts.

- There are two precision machined guide ways on the top of the bed viz., outer guide ways and inner guide ways.

- Headstock:

- The housing comprising the stepped cone pulley and feed gear box is called the headstock of the lathe.

- The headstock is rigidly mounted on the inner guide ways of lathe bed at its left end and is not movable.

- The main spindle projects out from the headstock and is driven at multiple speeds.

- Tailstock:

- Tailstock is the movable part of the lathe that carries the dead centre in it.

- It is mounted loosely on the inner guide ways of lathe bed on the right hand side and can be moved and locked in any position.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.