Podcast

Questions and Answers

What is the main function of a lathe machine?

What is the main function of a lathe machine?

- To design the cutting tool

- To lubricate the work piece

- To remove material from a work piece (correct)

- To secure the work piece

Who is credited with designing the first screw cutting lathe?

Who is credited with designing the first screw cutting lathe?

- Isaac Newton

- Henry Maudslay (correct)

- Alexander Graham Bell

- Thomas Edison

Which type of lathe is most common for ergonomic conveniences?

Which type of lathe is most common for ergonomic conveniences?

- Facing lathe

- Single purpose lathe

- Vertical lathe

- Horizontal lathe (correct)

What material is removed from the work piece in the form of chips during turning on a lathe machine?

What material is removed from the work piece in the form of chips during turning on a lathe machine?

Which type of lathe occupies less floor space?

Which type of lathe occupies less floor space?

In which year did Henry Maudslay design the first screw cutting lathe?

In which year did Henry Maudslay design the first screw cutting lathe?

What is the part of the carriage hanging in front of the bed called?

What is the part of the carriage hanging in front of the bed called?

Which movement is achieved by moving the cross slide on a lathe?

Which movement is achieved by moving the cross slide on a lathe?

What is the purpose of the lead screw in a lathe?

What is the purpose of the lead screw in a lathe?

Which mechanism is used to vary the feed rate for both turning and threading on a lathe?

Which mechanism is used to vary the feed rate for both turning and threading on a lathe?

What motion allows the tool to move axially for longitudinal feed on a lathe?

What motion allows the tool to move axially for longitudinal feed on a lathe?

Which part is engaged with the rotating lead screw to cause travel of the carriage during threading on a lathe?

Which part is engaged with the rotating lead screw to cause travel of the carriage during threading on a lathe?

What is used to shift the tailstock along the lathe bed when required?

What is used to shift the tailstock along the lathe bed when required?

What part is connected to the small end of the cone pulley in a back geared headstock?

What part is connected to the small end of the cone pulley in a back geared headstock?

What motion is attained by rotating the job in a lathe?

What motion is attained by rotating the job in a lathe?

What part is used to move the carriage or cross-slide for various operations in a lathe?

What part is used to move the carriage or cross-slide for various operations in a lathe?

What is the purpose of a capstan lathe?

What is the purpose of a capstan lathe?

Which type of lathe is most versatile and commonly used for medium duty work?

Which type of lathe is most versatile and commonly used for medium duty work?

What is the main function of the tailstock on a centre lathe?

What is the main function of the tailstock on a centre lathe?

Which part of a centre lathe moves in a direction parallel to the lathe axis?

Which part of a centre lathe moves in a direction parallel to the lathe axis?

In terms of precision, which type of lathe is meant for high accuracy and finish?

In terms of precision, which type of lathe is meant for high accuracy and finish?

What distinguishes a bar type lathe from a chucking type lathe?

What distinguishes a bar type lathe from a chucking type lathe?

Which type of automation is considered modern in lathes?

Which type of automation is considered modern in lathes?

What distinguishes single spindle lathes from multi-spindle lathes?

What distinguishes single spindle lathes from multi-spindle lathes?

On a center lathe, what is the function of the carriage?

On a center lathe, what is the function of the carriage?

What does the compound rest on a center lathe carry?

What does the compound rest on a center lathe carry?

What is the purpose of back gears B1 and B2 in the lathe mechanism described?

What is the purpose of back gears B1 and B2 in the lathe mechanism described?

Why is the all geared headstock preferred in modern lathes?

Why is the all geared headstock preferred in modern lathes?

In the context of feed mechanisms, what is the purpose of the tumbler gear reversing mechanism?

In the context of feed mechanisms, what is the purpose of the tumbler gear reversing mechanism?

How does changing the position of the lever in the tumbler gear reversing mechanism affect the direction of movement of the carriage?

How does changing the position of the lever in the tumbler gear reversing mechanism affect the direction of movement of the carriage?

What is one advantage of using a cone pulley mechanism in lathes?

What is one advantage of using a cone pulley mechanism in lathes?

Why are gears G4, G5, and G6 on the all geared headstock mounted on an intermediate shaft and cannot be moved axially?

Why are gears G4, G5, and G6 on the all geared headstock mounted on an intermediate shaft and cannot be moved axially?

What happens when back gear is engaged in lathe operations?

What happens when back gear is engaged in lathe operations?

Why does the all geared headstock mechanism result in almost constant power available at the tool for all spindle speeds?

Why does the all geared headstock mechanism result in almost constant power available at the tool for all spindle speeds?

In a lathe, what does engaging back gears do to the power flow in the mechanism?

In a lathe, what does engaging back gears do to the power flow in the mechanism?

What purpose does the lock pin serve when locking the step cone pulley with the main spindle?

What purpose does the lock pin serve when locking the step cone pulley with the main spindle?

What is the purpose of a quick-change gearbox in a lathe?

What is the purpose of a quick-change gearbox in a lathe?

How many different speeds can Shaft C receive in a lathe equipped with a quick-change gearbox?

How many different speeds can Shaft C receive in a lathe equipped with a quick-change gearbox?

In which mechanism is power transmitted from the feed rod to the worm wheel?

In which mechanism is power transmitted from the feed rod to the worm wheel?

What is the function of the splined shaft in a lathe's apron mechanism?

What is the function of the splined shaft in a lathe's apron mechanism?

How are various speeds obtained in a tumbler gear quick-change gearbox?

How are various speeds obtained in a tumbler gear quick-change gearbox?

What happens when the feed check knob 'E' is in a neutral position in an apron mechanism?

What happens when the feed check knob 'E' is in a neutral position in an apron mechanism?

How does the carriage move towards the tailstock?

How does the carriage move towards the tailstock?

Which shaft is connected to lead screw by a clutch and feed rod by a gear train in a lathe?

Which shaft is connected to lead screw by a clutch and feed rod by a gear train in a lathe?

What is the function of Shaft B in a lathe equipped with a quick-change gearbox?

What is the function of Shaft B in a lathe equipped with a quick-change gearbox?

How are various power feeds obtained in a lathe equipped with a quick-change gearbox?

How are various power feeds obtained in a lathe equipped with a quick-change gearbox?

What material is used to manufacture forged cutting tools?

What material is used to manufacture forged cutting tools?

How are ceramic inserts in tool holders fastened?

How are ceramic inserts in tool holders fastened?

In precision boring on a center lathe, where is the tool fitted?

In precision boring on a center lathe, where is the tool fitted?

Which method is used to attach tipped tools to carbon steel shanks?

Which method is used to attach tipped tools to carbon steel shanks?

What is the general material used for making solid tools?

What is the general material used for making solid tools?

How are ceramic inserts mounted in the tool post?

How are ceramic inserts mounted in the tool post?

What is the primary reason for using a solid tool?

What is the primary reason for using a solid tool?

What is the purpose of tipped tools fastened mechanically to carbon steel shanks?

What is the purpose of tipped tools fastened mechanically to carbon steel shanks?

Where are solid tools typically mounted in a lathe?

Where are solid tools typically mounted in a lathe?

How are tool bits usually secured in tool holders?

How are tool bits usually secured in tool holders?

How is longitudinal feed achieved in a lathe?

How is longitudinal feed achieved in a lathe?

What happens when the feed check knob 'E' is pulled-out?

What happens when the feed check knob 'E' is pulled-out?

Which mechanism provides rigidity in construction for feed reversing in modern lathes?

Which mechanism provides rigidity in construction for feed reversing in modern lathes?

What type of chuck is used for holding non-circular bars in a lathe?

What type of chuck is used for holding non-circular bars in a lathe?

What is the purpose of an angle plate in a lathe setup?

What is the purpose of an angle plate in a lathe setup?

How are the jaws of a 4 jaw chuck in a lathe moved radially?

How are the jaws of a 4 jaw chuck in a lathe moved radially?

Which component of a lathe setup consists of radial, plain, and T slots for holding work pieces?

Which component of a lathe setup consists of radial, plain, and T slots for holding work pieces?

What happens when the half nut is engaged with the carriage in a lathe?

What happens when the half nut is engaged with the carriage in a lathe?

What is the purpose of using an angle plate with the faceplate in a lathe machine?

What is the purpose of using an angle plate with the faceplate in a lathe machine?

What is the function of a catch plate or driving plate in a lathe machine?

What is the function of a catch plate or driving plate in a lathe machine?

What are carriers or dogs used for in a lathe machine?

What are carriers or dogs used for in a lathe machine?

Why are mandrels made of high carbon steel in a lathe machine?

Why are mandrels made of high carbon steel in a lathe machine?

When is a revolving centre preferably used in a lathe machine?

When is a revolving centre preferably used in a lathe machine?

What is the function of a pipe centre in a lathe machine?

What is the function of a pipe centre in a lathe machine?

How does a tipped centre differ from an ordinary centre in a lathe machine?

How does a tipped centre differ from an ordinary centre in a lathe machine?

What additional support is provided for long slender jobs like feed rod, lead screw etc. in a lathe machine?

What additional support is provided for long slender jobs like feed rod, lead screw etc. in a lathe machine?

How are tools usually mounted in a center lathe according to the information provided?

How are tools usually mounted in a center lathe according to the information provided?

What is the purpose of using an angle plate with the face plate in a lathe machine?

What is the purpose of using an angle plate with the face plate in a lathe machine?

Flashcards are hidden until you start studying

Study Notes

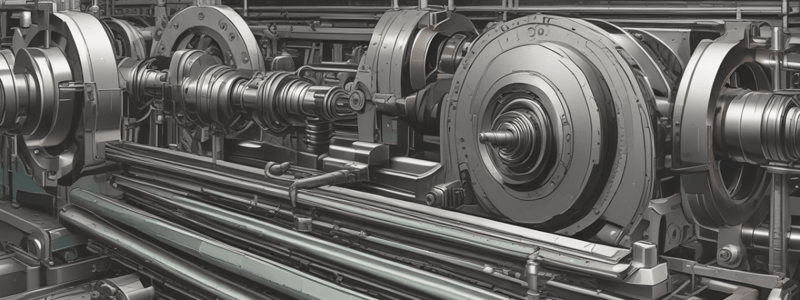

Centre Lathe

- A centre lathe is a machine tool used to remove material from a work piece to produce the required shape and size.

- It is the oldest machine tool invented, dating back to the Egyptian tree lathes.

- The main function of a centre lathe is to hold the work piece securely and rigidly on the machine and turn it against a cutting tool, which removes material from the work piece in the form of chips.

Components of a Centre Lathe

- Apron: The lower part of the carriage attached to the saddle and hangs in front of the bed. It contains gears, clutches, and levers for moving the carriage.

- Feed mechanism: The movement of the tool relative to the work piece is termed as "feed". There are three types of feed: longitudinal, cross, and angular.

- Feed rod: A long shaft used to move the carriage or cross-slide for turning, facing, boring, and other operations except thread cutting.

- Lead screw: A long threaded shaft used as a master screw and brought into operation only when threads have to be cut.

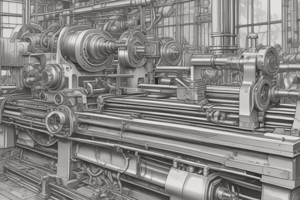

Kinematic System and Working Principle

- The job and the cutting tool need to be moved relative to each other.

- The tool-work motions are: formative motions (cutting motion, feed motion) and auxiliary motions (indexing motion, relieving motion).

- In lathes, cutting motion is attained by rotating the job, and feed motion is attained by linear travel of the tool.

Headstock Driving Mechanisms

- There are two types of headstock driving mechanisms: back geared headstock and all geared headstock.

- Back geared headstock: Used for reducing the spindle speed, necessary for thread cutting and knurling.

- All geared headstock: Commonly used in modern lathes due to its advantages, such as providing a wider range of spindle speeds, being more efficient and compact, and reducing vibration.

Feed Mechanisms

- The feed mechanism is used to transmit power from the spindle to the carriage.

- There are several types of feed mechanisms, including:

- Tumbler gear reversing mechanism

- Quick-change gearbox

- Tumbler gear quick-change gearbox

- Apron mechanism

- Bevel gear feed reversing mechanism

Tool Holding and Mounting

- Different types of tools are used in centre lathes, including:

- HSS tools (shank type)

- HSS form tools and threading tools

- Carbide and ceramic inserts

- Drills and reamers

- Boring tools

- Tools are mounted in various ways, including:

- HSS tools in tool post

- Carbide and ceramic inserts in tool holders

- Drills and reamers in tailstock

- Boring tools in tool post

Cutting Tools

- Single point cutting tools are used in centre lathes.

- Tools are classified according to:

- Method of manufacturing

- Method of holding

- Method of using

- Method of applying feed

- Types of cutting tools include:

- Forged tools

- Tipped tools brazed to the carbon steel shank

- Tipped tools fastened mechanically to the carbon steel shank

- Solid tools

- Tool bits inserted in tool holders### Classification of Lathes

- Lathes can be classified according to their special purpose, size or capacity, configuration of the jobs being handled, precision, and number of spindles.

- Special purpose lathes include capstan lathe, turret lathe, and gear blanking lathe.

- Lathes can be classified by size or capacity as small (up to 1.1 kW), medium (up to 11 kW), large (heavy duty), and mini or micro lathe.

Configuration of Jobs

- Lathes can be classified according to the configuration of the jobs being handled as bar type, chucking type, and housing type.

- Bar type lathes hold slender rod-like jobs in collets.

- Chucking type lathes hold disc-type jobs in chucks.

- Housing type lathes hold odd-shaped jobs in face plates.

Precision and Number of Spindles

- Lathes can be classified according to precision as ordinary and precision (high accuracy and finish).

- Lathes can be classified according to the number of spindles as single spindle (common) and multi-spindle (2, 4, 6, or 8 spindles).

Type of Automation

- Lathes can be classified according to the type of automation as fixed automation (conventional) and flexible automation (modern).

- Examples of fixed automation include single spindle automat and Swiss type automatic lathe.

- Examples of flexible automation include CNC lathe and turning centre.

Degree of Automation

- Lathes can be classified according to the degree of automation as non-automatic, semi-automatic, and automatic.

- Non-automatic lathes require manual handling operations.

- Semi-automatic lathes require some manual handling operations.

- Automatic lathes require minimal manual handling operations.

Constructional Features of Centre Lathes

- Centre lathes are the most versatile and commonly used lathes.

- Major parts of a centre lathe include headstock, tailstock, bed, carriage, saddle, cross-slide, compound rest, and tool post.

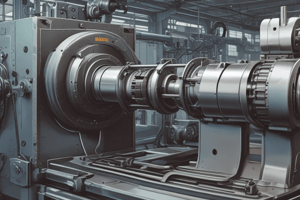

Headstock

- The headstock holds the spindle and transmits power and rotation to the job at different speeds.

- The headstock can hold various work-holding attachments such as three-jaw chucks, collets, and centres.

Tailstock

- The tailstock can be used to support the end of the workpiece with a centre, to support longer blanks, or to hold tools for drilling, reaming, threading, or cutting tapers.

- The tailstock can be adjusted in position along the ways to accommodate different length workpieces.

Bed, Carriage, and Saddle

- The bed is fixed on columns and the carriage travels on it.

- The carriage is used for giving various movements to the tool by hand and by power.

- The saddle carries the cross-slide, compound rest, and tool post.

Cross-Slide, Compound Rest, and Tool Post

- The cross-slide carries the compound rest and tool post.

- The compound rest is used during taper turning to set the tool for angular cuts.

- The tool post is fitted over the compound rest.

Quick-Change Gearbox and Tumbler Gear Quick-Change Gearbox

- The quick-change gearbox is used to get various power feeds in the lathe.

- The tumbler gear quick-change gearbox is simpler than the quick-change gearbox.

- Both types of gearboxes are used to obtain various speeds of the driving shaft.

Apron Mechanism

- The apron mechanism is used to transmit power from the spindle gear to the feed rod through tumbler gears.

- The apron mechanism is used for automatic feeds.

Mounting of Jobs in Centre Lathes

- Jobs can be mounted in centre lathes using chucks, face plates, and angle plates.

- Chucks can be 3-jaw self-centring or 4-jaw independent.

- Face plates have radial, plain, and T slots for holding work by bolts and clamps.

- Angle plates have two faces at right angles to each other with holes and slots for holding work.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.