Podcast

Questions and Answers

What is the primary focus of job order costing?

What is the primary focus of job order costing?

- Assigning costs to departments within a manufacturing facility

- Calculating the cost of each unique job or service (correct)

- Determining the average cost of production for a particular period

- Tracking costs for a specific product that is produced in large quantities

Which of the following is NOT a manufacturing cost that would be tracked under job order costing?

Which of the following is NOT a manufacturing cost that would be tracked under job order costing?

- Direct labor

- Direct materials

- Marketing expenses (correct)

- Factory overhead

What is the purpose of a job cost sheet?

What is the purpose of a job cost sheet?

- To record the total cost of manufacturing a product

- To provide a detailed breakdown of the costs incurred for each individual job (correct)

- To track the amount of materials used in production

- To calculate the overhead rate for a specific period

How does the flow of manufacturing costs differ between job order costing and process costing?

How does the flow of manufacturing costs differ between job order costing and process costing?

Which type of inventory account would hold the cost of materials used but not yet incorporated into a finished product?

Which type of inventory account would hold the cost of materials used but not yet incorporated into a finished product?

Which of the following is NOT a characteristic of job order costing?

Which of the following is NOT a characteristic of job order costing?

What is the correct sequence of steps for recording overhead costs in job order costing?

What is the correct sequence of steps for recording overhead costs in job order costing?

Which of the following is NOT a step in recording actual overhead costs?

Which of the following is NOT a step in recording actual overhead costs?

What is the purpose of the predetermined overhead rate?

What is the purpose of the predetermined overhead rate?

How is the predetermined overhead rate calculated?

How is the predetermined overhead rate calculated?

How is the actual overhead cost allocated to individual jobs?

How is the actual overhead cost allocated to individual jobs?

Which of the following is NOT an example of an indirect cost?

Which of the following is NOT an example of an indirect cost?

What is the primary purpose of a materials ledger card in a job order costing system?

What is the primary purpose of a materials ledger card in a job order costing system?

Which of the following documents is NOT directly involved in the flow of materials costs in a job order costing system?

Which of the following documents is NOT directly involved in the flow of materials costs in a job order costing system?

What is the purpose of a materials requisition?

What is the purpose of a materials requisition?

How does a receiving report relate to the flow of materials costs in a job order costing system?

How does a receiving report relate to the flow of materials costs in a job order costing system?

Which of the following statements is NOT true regarding the use of a materials ledger card?

Which of the following statements is NOT true regarding the use of a materials ledger card?

What is the difference between a materials requisition and a receiving report?

What is the difference between a materials requisition and a receiving report?

Why is it important to track the flow of materials costs in job order costing?

Why is it important to track the flow of materials costs in job order costing?

Which of the following is NOT a direct cost in a job order costing system?

Which of the following is NOT a direct cost in a job order costing system?

What is the primary objective of using job order costing?

What is the primary objective of using job order costing?

What is the purpose of a labor time ticket?

What is the purpose of a labor time ticket?

Which of the following is NOT a direct cost in job order costing?

Which of the following is NOT a direct cost in job order costing?

How is the predetermined overhead rate (POHR) calculated?

How is the predetermined overhead rate (POHR) calculated?

Why is a predetermined overhead rate commonly used in job order costing?

Why is a predetermined overhead rate commonly used in job order costing?

What is the purpose of applying overhead to jobs?

What is the purpose of applying overhead to jobs?

What is the basis for applying overhead in the example provided?

What is the basis for applying overhead in the example provided?

According to the information provided, what is Road Warriors' predetermined overhead rate?

According to the information provided, what is Road Warriors' predetermined overhead rate?

If a job requires $5,000 in direct labor cost, how much overhead would be applied to that job using Road Warriors' predetermined overhead rate?

If a job requires $5,000 in direct labor cost, how much overhead would be applied to that job using Road Warriors' predetermined overhead rate?

What is the purpose of applying overhead to a job using a predetermined overhead rate?

What is the purpose of applying overhead to a job using a predetermined overhead rate?

Flashcards

Job Order Costing

Job Order Costing

A costing system that assigns costs to specific jobs and tracks expenses for each job individually.

Job Cost Sheet

Job Cost Sheet

A record that accumulates all costs associated with a specific job, including materials, labor, and overhead.

Cost Flow Stages

Cost Flow Stages

The sequence of manufacturing costs from raw materials to cost of goods sold: Raw Materials, Work In Process, Finished Goods, Cost of Goods Sold.

Manufacturing Costs

Manufacturing Costs

Signup and view all the flashcards

Raw Materials Inventory

Raw Materials Inventory

Signup and view all the flashcards

Overhead Costs

Overhead Costs

Signup and view all the flashcards

Receiving Report

Receiving Report

Signup and view all the flashcards

Materials Ledger Card

Materials Ledger Card

Signup and view all the flashcards

Materials Requisition

Materials Requisition

Signup and view all the flashcards

Labor Cost Flow

Labor Cost Flow

Signup and view all the flashcards

Material Costs

Material Costs

Signup and view all the flashcards

Journal Entry for Materials

Journal Entry for Materials

Signup and view all the flashcards

Predetermined Overhead Rate

Predetermined Overhead Rate

Signup and view all the flashcards

Indirect Material

Indirect Material

Signup and view all the flashcards

Indirect Labor

Indirect Labor

Signup and view all the flashcards

Other Overhead Costs

Other Overhead Costs

Signup and view all the flashcards

Cost Flows to Financial Statements

Cost Flows to Financial Statements

Signup and view all the flashcards

Recording Cost Flows

Recording Cost Flows

Signup and view all the flashcards

Labor Time Ticket

Labor Time Ticket

Signup and view all the flashcards

Predetermined Overhead Rate (POHR)

Predetermined Overhead Rate (POHR)

Signup and view all the flashcards

Calculate POHR

Calculate POHR

Signup and view all the flashcards

Direct Labor Costs

Direct Labor Costs

Signup and view all the flashcards

Flow of Costs

Flow of Costs

Signup and view all the flashcards

Cost Allocation

Cost Allocation

Signup and view all the flashcards

Recording Costs

Recording Costs

Signup and view all the flashcards

Study Notes

Job Order Costing

- Job order costing is used by companies that produce custom orders and diverse products or services.

- These businesses often have low production volume and high product flexibility.

- Job order costing involves tracking costs for each specific job.

- Job cost sheets are used to record the cost of each job.

Learning Objectives

- C1: Explain job order costing and job cost sheets.

- A1: Apply job order costing in pricing services.

- P1: Describe and record the flow of materials costs in job order costing.

- P2: Describe and record the flow of labor costs in job order costing.

- P3: Describe and record the flow of overhead costs in job order costing.

- P4: Close overapplied and underapplied factory overhead.

Cost Accounting Systems

- Process costing vs. Job order costing: Process costing is used for repetitive procedures and high production volume, while job order costing is used for custom orders and diverse products/services.

- Job order operations - diverse products and services, low production volume, high product flexibility, low standardization.

- Process operations - repetitive procedures, similar products, high production volume, low product flexibility, high standardization.

Production Activities

- In job order costing, costs are tracked though Work in Process Inventory, Finished Goods Inventory, and Cost of Goods Sold.

- Raw materials are first recorded as Raw Materials Inventory and then transferred to Work in Process Inventory as needed.

- Direct labor costs related to a specific job are included in Work in Process Inventory.

- Overhead costs are applied to jobs using an estimated overhead rate.

- Completed products are moved to Finished Goods Inventory and then to Cost of Goods Sold after being sold..

Cost Flows

- Manufacturing costs flow through raw materials, work in process, finished goods, and cost of goods sold.

- Subsidiary records hold specific cost data about manufacturing costs for each job.

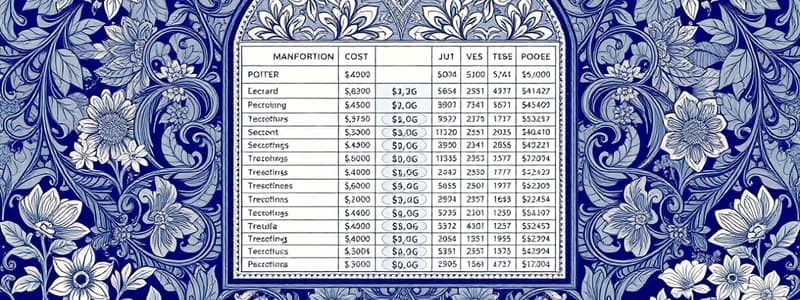

Job Cost Sheet

- Job cost sheets record the cost of each specific job.

Materials and Labor Costs

- Materials are recorded on receiving reports, materials ledger cards track materials used, then updated with material requisitions used for production.

- Labor costs are recorded on time tickets, which are used to track direct labor hours and wages; these are important for applying overhead costs.

Materials Requisition

- Materials requisitions are documents that authorize the removal of materials from inventory for specific jobs.

- These documents track both the quantity and cost of materials used for each job.

Materials Requisition Journal Entry, and Labor Time Ticket Journal Entry

- Journal entries record the flow of materials and labor costs into Work-in-Process.

Overhead Costs

- Predetermined overhead rate: Estimated overhead costs divided by estimated activity base.

- Overhead costs are applied to jobs based on a predetermined overhead rate.

- Actual overhead costs are recorded.

- Overapplied or underapplied overhead requires adjustment and closes to cost of goods sold.

Record Actual Overhead costs

- Indirect Material

- Indirect Labor

- Other Overhead Costs are recorded, these are not directly attributable to a specific job.

Record Actual Overhead Journal Entry

- Journal entries record the flow of overhead costs into Work-in-Process with factory overhead, indirect materials, and indirect labor costs included.

Cost Flows to Financial Statements

- Costs flow through raw materials, work in process, ending inventory, and cost of goods sold.

- The cost of Goods Sold is calculated to determine profit.

Accounting for Cost Flows

- The flow of cost information is linked to the accounts in the balance sheet and income statement.

Schedule of Cost of Goods Manufactured

- This schedule calculates the total manufacturing costs and the cost of goods manufactured.

Financial Statements

- Financial statements, including the income statement (sales, cost of goods sold, gross profit, etc.) and balance sheet (current assets, inventory, total inventory), show the results of the accounting for cost flows.

Adjusting Factory Overhead

- Overapplied or underapplied overhead needs to be adjusted, debiting or crediting cost of goods sold to correct any errors.

Job Order Costing for Services

- Service companies use job order costing, but there's no raw materials inventory. Direct labor and overhead costs are tracked in special service accounts.

- Different account titles (like Services in Process Inventory and Services Overhead) are used compared to manufacturing companies.

Pricing for Services

- Service providers must calculate total costs for each job (including labor and overhead) to determine pricing.

Gross Profit Ratio for Service Companies

- This ratio is calculated to ensure profitability within service-based business models.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.