Podcast

Questions and Answers

What is the primary material prepared during the Wafer Preparation process for Integrated Circuits?

What is the primary material prepared during the Wafer Preparation process for Integrated Circuits?

- Copper

- Germanium

- Silicon (correct)

- Gallium Arsenide

How does monocrystalline silicon differ from polycrystalline silicon?

How does monocrystalline silicon differ from polycrystalline silicon?

- Monocrystalline is less conductive.

- Monocrystalline has a continuous crystal lattice. (correct)

- Monocrystalline has disordered atomic structures.

- Monocrystalline has multiple grain boundaries.

Which technique is used specifically for obtaining monocrystalline semiconductors?

Which technique is used specifically for obtaining monocrystalline semiconductors?

- Bridgman Technique

- Float Zone Process

- Czochralski Pulling Technique (correct)

- Zone Melting

What is the purpose of the Zone Refining process in wafer preparation?

What is the purpose of the Zone Refining process in wafer preparation?

Which subprocess is performed after Ingot Surface Grinding in wafer preparation?

Which subprocess is performed after Ingot Surface Grinding in wafer preparation?

Which of the following characteristics accurately describes polycrystalline silicon?

Which of the following characteristics accurately describes polycrystalline silicon?

What step follows Wafer Rinsing in the wafer preparation process?

What step follows Wafer Rinsing in the wafer preparation process?

Which of the following steps is NOT part of the wafer preparation subprocesses?

Which of the following steps is NOT part of the wafer preparation subprocesses?

Study Notes

Integrated Circuits Overview

- Integrated Circuits (IC) consist of a collection of electronic components and their wiring, compacted onto a tiny slice of monocrystalline semiconductor material.

- Silicon, the primary material used for ICs, ranks as the second most abundant element on Earth, following Oxygen.

IC Manufacturing Process Stages

- The IC manufacturing process includes:

- Wafer Preparation

- Wafer Fabrication

- Wafer Sort

- Integrated Circuit Assembly

- Final Test

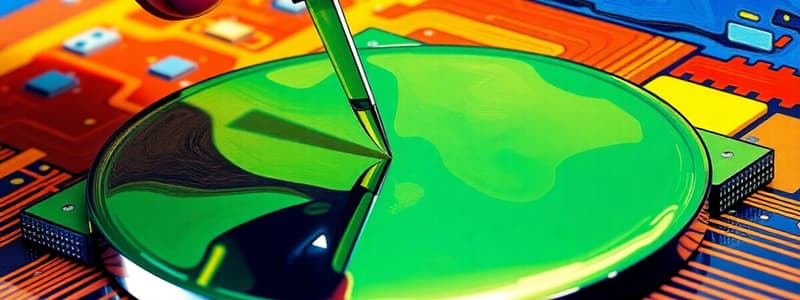

Wafer Preparation

- Wafer preparation is fundamental for IC production, focusing on silicon wafers as the main material.

Types of Silicon Crystals

- Monocrystalline Silicon:

- Characterized by a continuous and unbroken crystal lattice with no grain boundaries.

- Polycrystalline Silicon:

- Exhibits a more disordered structure, opposite the monocrystalline characteristics.

Subprocesses of Wafer Preparation

- Key subprocesses involve:

- Zone Refining

- Czochralski Pulling Technique

- Ingot Surface Grinding

- Ingot Slicing

- Wafer Scrubbing

- Wafer Rinsing

- Wafer Final Polish

- Resistivity Check and Inspection

Zone Refining

- Also known as zone melting or floating zone process, this technique allows for the purification of silicon.

- A narrow molten zone is moved along the crystal, melting impure solids at its leading edge and leaving behind purer material as it solidifies.

Czochralski Pulling Technique

- A crystal growth method used to produce monocrystalline semiconductors.

- Named after Jan Czochralski, who discovered this process in 1916 during experiments on the crystallization rates of metals.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz covers the essential aspects of wafer preparation in the context of integrated circuit (IC) testing and measurement. Participants will review the role of integrated circuits and their components as they relate to electronic engineering. Test your knowledge and understanding of this critical area in semiconductor technology.