Podcast

Questions and Answers

What does the elevated pressure inside the autoclave help achieve?

What does the elevated pressure inside the autoclave help achieve?

- Reduce the steam penetration into materials

- Decrease the sterilization efficiency

- Increase the boiling temperature of water (correct)

- Cause leaks in the autoclave

Which component of an autoclave should be regularly inspected and cleaned to prevent leaks?

Which component of an autoclave should be regularly inspected and cleaned to prevent leaks?

- Air filters

- Door gaskets (correct)

- Pressure gauge

- Steam valve

Why is calibration important for autoclaves?

Why is calibration important for autoclaves?

- To decrease the boiling temperature of water

- To clean the autoclave

- To increase steam penetration

- To ensure accuracy in temperature and pressure readings (correct)

What is a key aspect of autoclave maintenance to prevent breakdowns?

What is a key aspect of autoclave maintenance to prevent breakdowns?

Why is documentation of maintenance activities important for autoclaves?

Why is documentation of maintenance activities important for autoclaves?

What particles make up all atoms?

What particles make up all atoms?

What defines an electrical charge on an atom?

What defines an electrical charge on an atom?

According to the law of electric charges, what happens between like charges?

According to the law of electric charges, what happens between like charges?

Which type of charges repel each other?

Which type of charges repel each other?

What happens between unlike charges according to the law of electric charges?

What happens between unlike charges according to the law of electric charges?

Flashcards are hidden until you start studying

Study Notes

Autoclaves: Sterilization, Pressure Vessels, and Maintenance

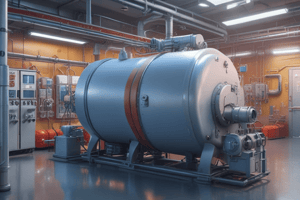

Autoclaves are enclosed, airtight chambers used to sterilize various types of materials, from medical supplies and lab equipment to food products. In this article, we'll explore the fundamentals of autoclave sterilization, their function as pressure vessels, and the importance of proper maintenance to ensure safe and effective sterilization processes.

Sterilization Methods

Autoclaves employ a variety of sterilization methods to meet different needs. Common techniques include:

-

Wet heat sterilization: This method involves exposing items to high temperatures in the presence of steam, typically around 121°C (250°F). Wet heat sterilization is ideal for porous materials that can absorb steam, such as cotton and gauze.

-

Dry heat sterilization: In this method, items are exposed to high temperatures in the absence of moisture, typically at 160-170°C (320-338°F). Dry heat sterilization is used for items that cannot withstand steam or have a low steam penetration rate, such as metal instruments.

-

Moist heat sterilization with chemicals: In some cases, chemicals like sodium hydroxide or hydrogen peroxide are added to the steam within the autoclave to enhance sterilization. This method is particularly useful for items that require decontamination or disinfection in addition to sterilization, such as surgical instruments.

Pressure Vessels

Autoclaves are designed to operate at elevated pressures to maximize sterilization efficiency. Pressure inside the autoclave is controlled by a valve that releases steam to regulate the internal pressure. The elevated pressure:

- Increases the boiling temperature of water, allowing for higher temperatures to be reached and maintained.

- Enhances steam penetration into porous materials, ensuring more effective sterilization.

The pressure within the autoclave is typically monitored using a pressure gauge and may range from atmospheric pressure (1 atm) to 2-3 times atmospheric pressure, depending on the specific autoclave and the materials being sterilized.

Autoclave Maintenance

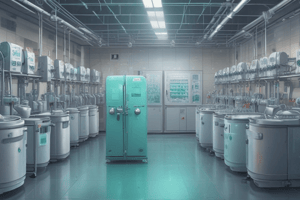

Regular maintenance of autoclaves is crucial to ensure their long-term performance and safety. Key aspects of autoclave maintenance include:

-

Inspection and cleaning: Components such as door gaskets, air filters, and water traps should be inspected and cleaned regularly to prevent leaks and ensure proper function.

-

Calibration: Autoclaves require periodic calibration to ensure accuracy in temperature and pressure readings.

-

Repair and maintenance: Regular maintenance checks should be performed to identify any malfunctions or signs of wear and tear. This will help prevent breakdowns and ensure safe operation.

-

Safety checks: Autoclaves must adhere to rigorous safety standards, and regular safety checks should be performed to ensure that the unit is functioning as designed.

-

Documentation: All maintenance activities should be documented to ensure accountability and traceability of autoclave performance.

By following proper maintenance procedures, autoclaves can maintain their performance and contribute to the safety and effectiveness of sterilization processes in various applications.

Conclusion

Autoclaves are essential tools for sterilization and disinfection, serving numerous industries. Proper understanding of autoclave sterilization methods, their function as pressure vessels, and the importance of maintenance ensures safe and effective operation. By following maintenance guidelines, users can maximize the lifespan and performance of their autoclaves, thereby contributing to a safer and healthier environment.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.