Podcast

Questions and Answers

What is the primary function of an aircraft reciprocating engine?

What is the primary function of an aircraft reciprocating engine?

- To provide electrical power for the aircraft's systems.

- To turn the propeller, creating thrust to propel the aircraft. (correct)

- To control the aircraft's flight surfaces.

- To generate lift for the aircraft.

Which component in a reciprocating engine is responsible for converting the linear motion of the pistons into rotational motion?

Which component in a reciprocating engine is responsible for converting the linear motion of the pistons into rotational motion?

- Camshaft

- Crankshaft (correct)

- Valve

- Connecting rod

In a reciprocating engine, what is the purpose of the valves?

In a reciprocating engine, what is the purpose of the valves?

- To control the intake of the fuel-air mixture and the exhaust gases' exit from the cylinder. (correct)

- To control the flow of fuel into the cylinders.

- To regulate the temperature of the engine.

- To ignite the fuel-air mixture.

What do connecting rods do in the context of a reciprocating engine?

What do connecting rods do in the context of a reciprocating engine?

What is the function of the cooling system, whether liquid or air-cooled, in a reciprocating engine?

What is the function of the cooling system, whether liquid or air-cooled, in a reciprocating engine?

Which of the following best describes the role of the camshaft in a reciprocating engine?

Which of the following best describes the role of the camshaft in a reciprocating engine?

What is the operational difference between older reciprocating engines and modern ones in terms of fuel-air mixture?

What is the operational difference between older reciprocating engines and modern ones in terms of fuel-air mixture?

What is the main purpose of the oil system in a reciprocating engine?

What is the main purpose of the oil system in a reciprocating engine?

Which of the following is an advantage of using reciprocating engines in aircraft?

Which of the following is an advantage of using reciprocating engines in aircraft?

What is a significant limitation of reciprocating engines, especially concerning altitude performance?

What is a significant limitation of reciprocating engines, especially concerning altitude performance?

What causes the power stroke?

What causes the power stroke?

What is the correct order of the strokes?

What is the correct order of the strokes?

What is the purpose of a spark plug?

What is the purpose of a spark plug?

What kind of aircraft commonly uses reciprocating engines?

What kind of aircraft commonly uses reciprocating engines?

Which stroke expels gases?

Which stroke expels gases?

What happens during the intake stroke?

What happens during the intake stroke?

What is the main advantage of using reciprocating engines in smaller aircraft regarding fuel?

What is the main advantage of using reciprocating engines in smaller aircraft regarding fuel?

Why is it important to adhere to safety protocols and procedures within a maintenance lab?

Why is it important to adhere to safety protocols and procedures within a maintenance lab?

Why is regular attendance important?

Why is regular attendance important?

Why shouldn't trainees go home until a missing tool is found?

Why shouldn't trainees go home until a missing tool is found?

Flashcards

Aircraft Reciprocating Engine

Aircraft Reciprocating Engine

An engine type that converts reciprocating motion of pistons into rotational motion to turn an aircraft's propeller.

Crankshaft

Crankshaft

The main rotating shaft that converts the linear motion of the pistons into rotational motion.

Pistons

Pistons

Components that move up and down inside the cylinders to compress the air-fuel mixture and transmit power.

Cylinders

Cylinders

Signup and view all the flashcards

Spark Plugs

Spark Plugs

Signup and view all the flashcards

Valves

Valves

Signup and view all the flashcards

Connecting Rods

Connecting Rods

Signup and view all the flashcards

Camshaft

Camshaft

Signup and view all the flashcards

Carburetor or Fuel Injectors

Carburetor or Fuel Injectors

Signup and view all the flashcards

Oil System

Oil System

Signup and view all the flashcards

Cooling System

Cooling System

Signup and view all the flashcards

Intake

Intake

Signup and view all the flashcards

Compression

Compression

Signup and view all the flashcards

Ignition

Ignition

Signup and view all the flashcards

Power

Power

Signup and view all the flashcards

Exhaust

Exhaust

Signup and view all the flashcards

Simplicity and Reliability

Simplicity and Reliability

Signup and view all the flashcards

Cost-Effective

Cost-Effective

Signup and view all the flashcards

Fuel Efficiency

Fuel Efficiency

Signup and view all the flashcards

Higher Maintenance

Higher Maintenance

Signup and view all the flashcards

Study Notes

- This presentation provides an introduction to aircraft reciprocating engines at DPR Aviation College, taught by Mr. John Mark E. Dizon.

- The syllabus involves 7 hours of weekly instruction over 26 days, totaling 108 hours.

- Students are expected to attend class, participate actively, and submit assignments on time, with late work penalized by 10% per day, and work more than 5 days late not accepted.

- Academic integrity is required; dishonesty is not tolerated, and all submissions must be the student's original work with proper citations.

- For questions, the instructor is the primary contact, reachable via email during weekday working hours.

Subject Rules

- Students must check G-Class announcements, wear the correct uniform, and bring required PPE.

- Students must be on time and in the designated area, attending the attendance roll call.

- A task card must be requested for guidance on assigned work, roles assigned within the team, and tools audited before task execution.

- During the task, phone use is limited to the documenter, steps on the task card must be followed, and the work area must be kept clean.

- Scheduled breaks should be taken, hydration maintained, and any unwellness reported immediately.

- Completed work must be endorsed by the instructor, tools audited, and work details logged in both personal and aircraft logbooks.

Grading System

- Attendance and punctuality in laboratory sessions account for 15% of the grade.

- Adherence to safety protocols, PPE use, and tool handling in the maintenance lab counts for 10%.

- Hands-on skills assessment makes up 45% of the grade, including inspections, maintenance, troubleshooting, documentation, and lab participation.

- Midterm and final exams each contribute 15%, covering theoretical knowledge and practical skills.

Learning Objectives

- Understand reciprocating engines.

- Identify the common parts of reciprocating engines.

- Understand how reciprocating engines work.

- Identify the types of reciprocating engines.

- Practice using a micrometer and feeler gauge.

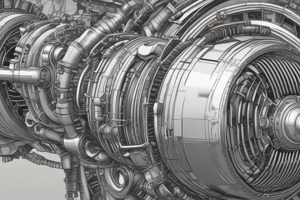

Reciprocating Engines

- The primary purpose of the reciprocating engine in an aircraft is to turn the propeller, which thrusts the aircraft forward.

- This engine type is an internal combustion engine commonly used in general aviation and smaller aircraft, burning a fuel and air mixture (avgas).

Common Parts

- The crankshaft converts the reciprocating motion of pistons into rotational motion to turn the propeller.

- Pistons move up and down within cylinders during combustion.

- Cylinders house the pistons and provide space for fuel-air mixture combustion.

- Spark plugs ignite the fuel-air mixture to start combustion.

- Valves control the intake of the fuel-air mixture and exhaust gases, including intake and exhaust valves.

- Connecting rods link pistons to the crankshaft.

- The camshaft controls valve timing, and carburetors/fuel injectors mix fuel with air before it enters the cylinders; modern engines often use fuel injection.

- The oil system lubricates parts to reduce wear, and the cooling system prevents overheating, typically through liquid or air cooling.

Types of Reciprocating Engines

- In-line

- V-type

- Opposed (horizontal or vertical)

- Radial

Basic Operation

- Intake: Air and fuel are drawn in and mixed in the carburetor or fuel injector system.

- Compression: Pistons compress the mixture inside the cylinders.

- Ignition: A spark plug ignites the compressed mixture, creating an explosion that forces the piston down.

- Power: The downward movement turns the crankshaft, powering the propeller.

- Exhaust: The piston moves upward, expelling exhaust gases to complete the cycle.

- This cycle repeats continuously.

Manufacturers

- Continental Aerospace Technologies

- Lycoming

Advantages

- Simplicity and reliability compared to turbine engines, making them easier to maintain and repair.

- They are more cost-effective, being generally more affordable than jet engines in terms of purchase price and maintenance.

- Better fuel efficiency compared to larger jet engines in smaller aircraft is characteristic.

Disadvantages

- Reciprocating engines have limited power compared to turbine engines, which can limit aircraft size and performance.

- These engines need higher maintenance, including components like spark plugs, cylinders, and valves.

- Altitude performance is lower; they lose performance at higher altitudes due to decreased air density.

Common Uses

- Light aircraft like the Piper Archer, Beechcraft B58 Baron, Piper J3 Cub, and Piper Aztec.

- Trainer aircraft like the Cessna 150, Piper Tomahawk, and Cessna 172

- Small commercial and cargo aircraft

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.