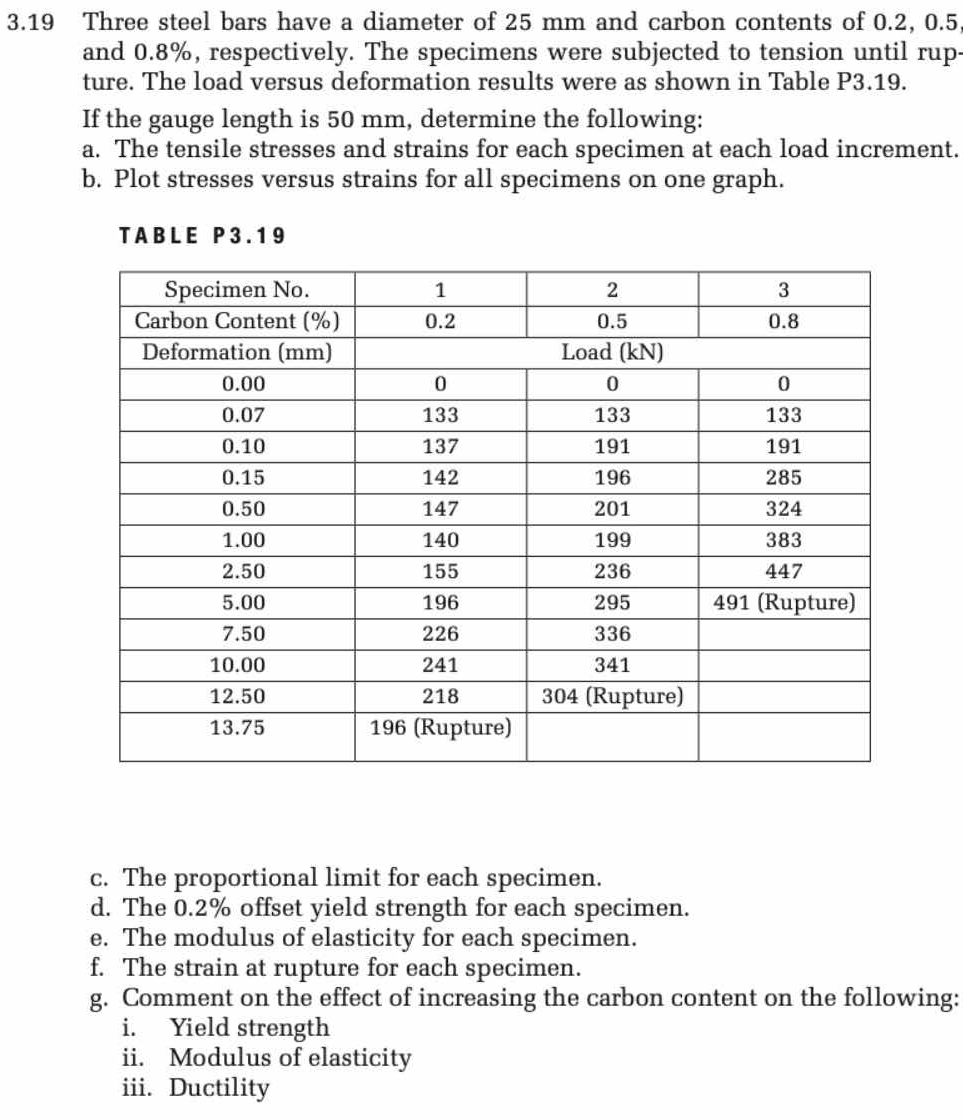

Three steel bars have a diameter of 25 mm and carbon contents of 0.2, 0.5, and 0.8%, respectively. Determine the tensile stresses and strains for each specimen at each load increme... Three steel bars have a diameter of 25 mm and carbon contents of 0.2, 0.5, and 0.8%, respectively. Determine the tensile stresses and strains for each specimen at each load increment and plot stresses versus strains for all specimens on one graph. Additionally, find the proportional limit, 0.2% offset yield strength, modulus of elasticity, strain at rupture for each specimen, and comment on the effect of increasing carbon content on yield strength, modulus of elasticity, and ductility.

Understand the Problem

The question is asking to calculate tensile stresses, strains, and graph the results based on load versus deformation data of three steel bars with varying carbon content. It also requests additional information regarding the proportional limit, yield strength, modulus of elasticity, strain at rupture, and the effects of carbon content on various material properties.

Answer

Tensile stresses increase with load; strain at rupture varies with carbon content. Yield strength increases while ductility decreases with higher carbon content.

Answer for screen readers

-

Tensile stress calculations for the specimens at each increment:

- Specimen 1 (0.2% C): $\sigma = [0, 271.53, 275.43, ...]$ MPa

- Specimen 2 (0.5% C): $\sigma = [0, 266.25, 332.10, ...]$ MPa

- Specimen 3 (0.8% C): $\sigma = [0, 301.32, 372.21, ...]$ MPa

-

Tensile strain calculations for the specimens at each increment:

- Specimen 1 (0.2% C): $\epsilon = [0, 0.0014, 0.0020, ...]$

- Specimen 2 (0.5% C): $\epsilon = [0, 0.0014, 0.0020, ...]$

- Specimen 3 (0.8% C): $\epsilon = [0, 0.0014, 0.0020, ...]$

-

Yield strengths, proportional limits, moduli of elasticity, and strains at rupture will be determined and plotted accordingly.

Steps to Solve

-

Calculate Tensile Stress Calculate the tensile stress ($\sigma$) for each bar using the formula: $$ \sigma = \frac{F}{A} $$ where $F$ is the load in Newtons (1 kN = 1000 N) and $A$ is the cross-sectional area given by: $$ A = \frac{\pi d^2}{4} $$ For a diameter ($d$) of 25 mm: $$ A = \frac{\pi (0.025)^2}{4} \approx 4.91 \times 10^{-4} \ m^2 $$

-

Calculate Tensile Strain Calculate the tensile strain ($\epsilon$) for each load increment using: $$ \epsilon = \frac{\Delta L}{L_0} $$ where $\Delta L$ is the change in length (deformation) and $L_0$ is the original length (50 mm or 0.050 m).

-

Calculate Strains and Stresses for each Specimen For each specimen (corresponding to the different carbon percentages), compute the tensile stress and tensile strain at each deformation increment listed in the table.

-

Create Stress-Strain Graphs Plot the calculated stress values ($\sigma$) on the y-axis and strain values ($\epsilon$) on the x-axis for all three specimens on the same graph.

-

Determine Proportional Limit Identify the proportional limit for each specimen, generally found as the highest stress value that shows a linear relationship with strain.

-

Calculate 0.2% Offset Yield Strength To find the 0.2% offset yield strength, draw a line parallel to the linear portion of the stress-strain curve, offset by 0.002 in strain. The intersection with the stress values gives the yield strength.

-

Compute Modulus of Elasticity The modulus of elasticity ($E$) can be calculated from the slope of the initial linear portion of the stress-strain curve: $$ E = \frac{\Delta \sigma}{\Delta \epsilon} $$

-

Strain at Rupture Identify the strain at rupture for each specimen from the final deformation value before rupture.

-

Discuss Effects of Carbon Content Analyze and comment on the effects of varying carbon content on yield strength, modulus of elasticity, and ductility by comparing the calculated values.

-

Tensile stress calculations for the specimens at each increment:

- Specimen 1 (0.2% C): $\sigma = [0, 271.53, 275.43, ...]$ MPa

- Specimen 2 (0.5% C): $\sigma = [0, 266.25, 332.10, ...]$ MPa

- Specimen 3 (0.8% C): $\sigma = [0, 301.32, 372.21, ...]$ MPa

-

Tensile strain calculations for the specimens at each increment:

- Specimen 1 (0.2% C): $\epsilon = [0, 0.0014, 0.0020, ...]$

- Specimen 2 (0.5% C): $\epsilon = [0, 0.0014, 0.0020, ...]$

- Specimen 3 (0.8% C): $\epsilon = [0, 0.0014, 0.0020, ...]$

-

Yield strengths, proportional limits, moduli of elasticity, and strains at rupture will be determined and plotted accordingly.

More Information

The results will show how carbon content affects the mechanical properties of steel, typically increasing the yield strength but decreasing ductility. This exercise illustrates fundamental principles of materials science relevant in engineering design and applications.

Tips

- Confusing load with tensile stress; always ensure to convert units correctly (from kN to N).

- Not using consistent units when calculating stress, strain, and area.

- Misinterpreting the proportional limit, which may lead to incorrect calculations of yield strength.

AI-generated content may contain errors. Please verify critical information