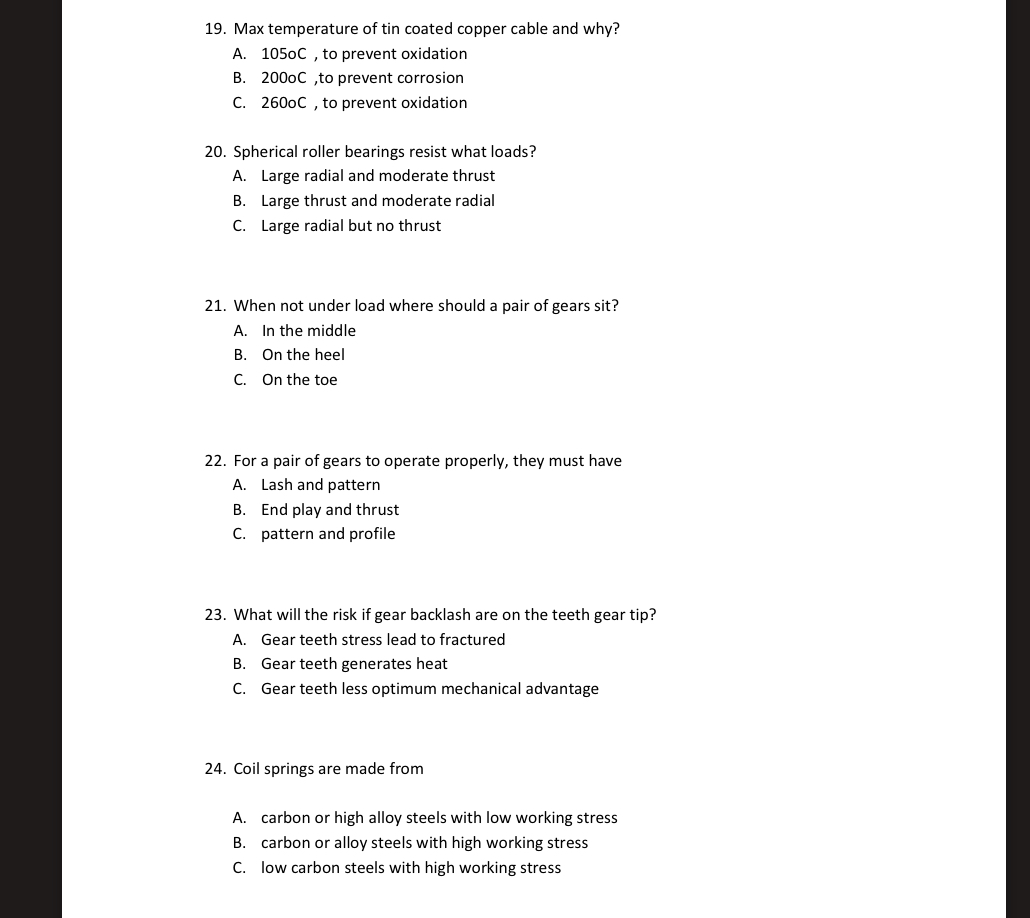

Max temperature of tin coated copper cable and why? Spherical roller bearings resist what loads? When not under load where should a pair of gears sit? For a pair of gears to operat... Max temperature of tin coated copper cable and why? Spherical roller bearings resist what loads? When not under load where should a pair of gears sit? For a pair of gears to operate properly, they must have? What will the risk if gear backlash are on the teeth gear tip? Coil springs are made from?

Understand the Problem

The questions in the image pertain to engineering concepts, specifically regarding materials, gears, and mechanical loads. They require understanding of properties and behaviors of materials and mechanical systems.

Answer

19: C, 20: A, 21: A, 22: C, 23: A, 24: B.

19: C - 260°C to prevent oxidation. 20: A - Large radial and moderate thrust. 21: A - In the middle. 22: C - Pattern and profile. 23: A - Gear teeth stress lead to fractured. 24: B - Carbon or alloy steels with high working stress.

Answer for screen readers

19: C - 260°C to prevent oxidation. 20: A - Large radial and moderate thrust. 21: A - In the middle. 22: C - Pattern and profile. 23: A - Gear teeth stress lead to fractured. 24: B - Carbon or alloy steels with high working stress.

More Information

- Tin coated copper cable's temperature helps prevent oxidation.

- Spherical roller bearings handle large radial and moderate thrust loads.

- Gears should sit in the middle.

- Proper gear operation requires correct pattern and profile.

- Backlash risk involves stress fracture.

- Coil springs are made from strong materials.

Tips

Ensure proper material selection for coil springs based on stress levels.

AI-generated content may contain errors. Please verify critical information