Podcast

Questions and Answers

What primary component replaces the beard or latch needle in modern warp knitting machines?

What primary component replaces the beard or latch needle in modern warp knitting machines?

- Latch needled warp

- Compound needle (correct)

- Flat needle

- Beard needle

Which action occurs immediately after the guides shog for the overlap in the knitting process?

Which action occurs immediately after the guides shog for the overlap in the knitting process?

- The hooks and tongues begin to ascend.

- The sinkers withdraw to release the finished loop.

- The needles start their downward movement. (correct)

- The sinkers press down to tighten the fabric.

What characteristic distinguishes warp knitted fabrics from weft knitted fabrics?

What characteristic distinguishes warp knitted fabrics from weft knitted fabrics?

- Higher elasticity

- More stable construction (correct)

- Wider range of colors available

- More breathable in nature

In which situation is warp knitted fabric commonly utilized?

In which situation is warp knitted fabric commonly utilized?

Which of the following is NOT a typical product of warp knitting?

Which of the following is NOT a typical product of warp knitting?

Flashcards

Compound-Needle Warp Knitting Machine

Compound-Needle Warp Knitting Machine

A type of knitting machine that uses compound needles for increased productivity instead of traditional beard or latch needles.

Knitting Action (Needle Rise & Guide)

Knitting Action (Needle Rise & Guide)

The initial stage of knitting, where needles rise, guides swing to the back, and hooks/tongues open for loop creation.

Warp Knitted Fabric Properties

Warp Knitted Fabric Properties

Warp knitted fabrics are generally more stable, allow for various designs, big/small holes, and the use of coarse yarns.

Knitting Action (Overlap & Return)

Knitting Action (Overlap & Return)

Signup and view all the flashcards

Warp Knitted Fabric Uses

Warp Knitted Fabric Uses

Signup and view all the flashcards

Study Notes

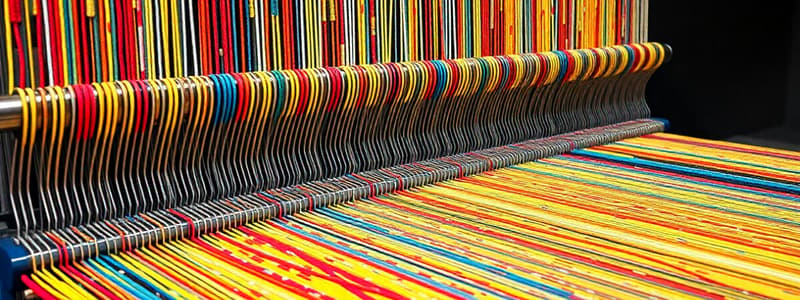

Compound Needle Warp Knitting Machine

- Compound needles are used in warp knitting machines to increase productivity, replacing beard or latch needles.

Components of the Machine

- Compound Needle (main Body): A crucial part of the machine's structure.

- Compound Needle (Closing Element): An essential component in the closing process.

- Trick Plate: A component in the mechanism.

- Sinker: A component that controls the fabric.

- Yarn End: The yarn supply.

- Yarn Guide: Directs the yarn.

- Fabric: The final product.

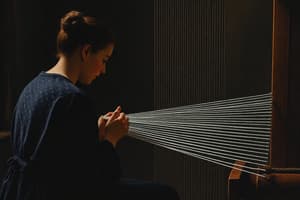

Knitting Action

- Step 1: Needles rise, guide bars swing; sinkers hold fabric down, hooks and tongues rise up, hook rises faster than tongue until it aligns with guide holes. Guides then swing to the back of the machine.

- Step 2: Guides overlap, return swing; hooks and tongues descend, tongues descend slower closing hooks.

- Step 3: Landing and knock-over; sinkers withdraw, needles descend, loop lands on closed hook, then knocked over as it descends below the sinker belly. Underlap occurs before needles rise and sinkers hold fabric down.

Comparison of Tricot and Raschel Machines

- Tricot:

- Uses bearded needles or compound needles.

- Typically finer gauge (28-32 needles per inch).

- Suitable for finer filaments.

- Fewer guide bars (2-4).

- Fewer warp beams.

- Sinkers control fabric throughout knitting cycle.

- Needle-fabric angle 90°.

- Produces simple fabrics.

- Higher machine speed.

- Lower knitting tension.

- Wider machine.

- Lighter fabric

- More resilient, better drape, higher bursting strength, better dimensional stability, soft hand, and even opaque and tight.

- Raschel:

- Uses latch needles.

- Coarser gauge (8-16 needles per inch).

- Suitable for spun yarn, coarser filaments, or decorative staple spun yarn.

- More guide bars (6-48).

- More warp beams.

- Sinkers only ensure fabric stays down.

- Needle-fabric angle 160°.

- Produces more complex fabrics.

- Lower machine speed.

- Higher knitting tension

- Narrower machine.

- Heavier fabric

- Less resilient, poor drape, lower bursting strength, and poor dimensional stability, hard hand, uneven and loose.

Warp Knitted Fabric Properties

- More stable than weft knitted fabrics.

- Can produce big and small holes.

- Offers a variety of designs.

- Can use highly course yarn.

- Suitable for technical fabrics.

Main Warp Knitted Products

- Nets

- Curtains

- Technical fabrics

- Covers

- Covering sheets

Warp Knitted Fabric Uses

- Uses for technical demands (filters, seat covers, etc.)

- Curtains and table covers

- Bed sheets

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.