Podcast

Questions and Answers

What characteristic distinguishes warp knitting from weft knitting?

What characteristic distinguishes warp knitting from weft knitting?

- Warp knitting is done exclusively by hand.

- Warp knitting produces thicker fabrics than weft knitting.

- Warp knitting uses parallel rows of loops. (correct)

- Warp knitting requires only one type of yarn.

Which of the following statements about warp knitted fabrics is true?

Which of the following statements about warp knitted fabrics is true?

- The loops are larger than those in double knitted fabrics.

- They are typically thicker than double knitted fabrics.

- Most warp knitted fabrics form a clean and balanced loop on the surface. (correct)

- They are produced in a single course rather than multiple courses.

How is the fabric formed in warp knitting?

How is the fabric formed in warp knitting?

- Yarns are woven together in horizontal rows.

- Yarns are knitted course by course in a circular pattern.

- Yarns are interlocked with no specific pattern.

- Yarns are knitted simultaneously on adjacent needles course by course. (correct)

What is a common difference in appearance between the technical face and back of warp knitted fabrics?

What is a common difference in appearance between the technical face and back of warp knitted fabrics?

What type of machine is primarily used for warp knitting?

What type of machine is primarily used for warp knitting?

What machine speed was attained with the compiled guide bars and bearded needles?

What machine speed was attained with the compiled guide bars and bearded needles?

Which of the following accurately describes the loop formation in warp knitting?

Which of the following accurately describes the loop formation in warp knitting?

How many yarn ends may be fed to the needles in weft knitting?

How many yarn ends may be fed to the needles in weft knitting?

What is a key advantage of warp knitted fabric compared to weft knitted fabric?

What is a key advantage of warp knitted fabric compared to weft knitted fabric?

In the process of warp knitting, what happens to all the needles?

In the process of warp knitting, what happens to all the needles?

What does the term 'wales' refer to in the context of knitting?

What does the term 'wales' refer to in the context of knitting?

Which aspect distinguishes warp knitting from weft knitting in terms of structure?

Which aspect distinguishes warp knitting from weft knitting in terms of structure?

What modification can improve the structure of warp knitted fabric?

What modification can improve the structure of warp knitted fabric?

What is the primary characteristic of stitches in warp knitting?

What is the primary characteristic of stitches in warp knitting?

Which inventor is credited with laying the foundations for mechanical warp knitting technology?

Which inventor is credited with laying the foundations for mechanical warp knitting technology?

What is indicated by the term 'laps' in warp knitting?

What is indicated by the term 'laps' in warp knitting?

How does warp knitting differ from traditional weft knitting in terms of yarn feeding?

How does warp knitting differ from traditional weft knitting in terms of yarn feeding?

What kind of stability do warp knitted fabrics exhibit compared to woven fabrics?

What kind of stability do warp knitted fabrics exhibit compared to woven fabrics?

Which feature is associated with the warp beam in warp knitting?

Which feature is associated with the warp beam in warp knitting?

In terms of output, how many stitches can a modern warp knitting machine produce per minute?

In terms of output, how many stitches can a modern warp knitting machine produce per minute?

What type of fabric can warp knitting produce?

What type of fabric can warp knitting produce?

Flashcards

Warp Knitting

Warp Knitting

A loop-forming process of weft-knit using machines where yarns are fed parallel to the fabric's selvedge.

Warp Knitting Machines

Warp Knitting Machines

Machines used for warp knitting; they use warp beams for yarn supply.

Warp Beam

Warp Beam

A beam containing many parallel yarns, similar to a weaving loom.

Laps/Under Laps

Laps/Under Laps

Signup and view all the flashcards

William Lee

William Lee

Signup and view all the flashcards

Karl Mayer

Karl Mayer

Signup and view all the flashcards

Warp Knitted Fabrics

Warp Knitted Fabrics

Signup and view all the flashcards

Modern Warp Knitting Machine Speed

Modern Warp Knitting Machine Speed

Signup and view all the flashcards

Weft knitted fabric

Weft knitted fabric

Signup and view all the flashcards

Dimensional stability

Dimensional stability

Signup and view all the flashcards

Warp knitting speed

Warp knitting speed

Signup and view all the flashcards

Knitting machine

Knitting machine

Signup and view all the flashcards

Loop formation in knitting

Loop formation in knitting

Signup and view all the flashcards

Warp Knit Fabric Thickness

Warp Knit Fabric Thickness

Signup and view all the flashcards

Warp Knit Fabric Appearance

Warp Knit Fabric Appearance

Signup and view all the flashcards

Study Notes

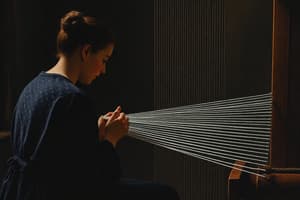

Warp Knitting Basics

- Warp knitting is a loop-forming process where yarn is fed parallel to the fabric selvedge.

- The process differs from weft knitting, with each needle having its own thread, creating one warp for one wale.

- Warp yarn is fed from a warp beam, similar to a loom. Multiple warps may be used for complex designs.

- Warp knitting machines can produce flat or tubular fabric in various patterns.

- Modern warp knitting machines are highly efficient, capable of high production speeds and wide fabric widths, up to 168 inches.

History and Technology

- William Lee patented the first machine for knitted articles in 1589.

- Karl Mayer demonstrated a warp knitting loom in 1947, marking a significant technical advancement with higher speed and two guide bars with bearded needles (200 rpm).

- Warp knitting machines have evolved significantly, influencing the technical era of textile production.

- Crucial elements: two guide bars, bearded needles, and loop formation (warp-wise).

Fabric Structure and Characteristics

- Warp knitted loop formation produces stitches arranged vertically but at a slight angle on the fabric face and horizontally (floats).

- Loops appear horizontally on the fabric back. This characteristic (floats) distinguishes warp knits.

- Warp knit fabrics are known for dimensional stability, comparable to woven fabrics.

- Warp knitted fabrics are available in different types like: Tricot, Raschel knits etc.

Loop Formation

- In warp knitting, each needle is supplied with a single or multiple yarns, and needles knit simultaneously to produce an entire course at once.

- Loop formation is warp-wise (vertically).

- The inter-locking loops create a zigzag pattern and are knitted course by course, forming the fabric.

- The needles loop the warp yarns, which interlock with adjacent loops, creating the fabric.

Advantages of Warp Knit Fabric

- Dimensional stability: Generally more stable than weft knitted fabrics.

- Tightness: Fabric is tight and loops are small, giving a clean surface.

- Appearance: Nice, clean and balanced loop appearance, usually distinct front and back surfaces.

Disadvantages of Warp Knit Fabric

- Raw material: Not all yarns are suitable for warp knitting. Filament yarns with high strength and a smooth surface are ideal.

- Yarn count: Usually requires fine yarn counts (50-70 deniers) for optimal results.

- Small orders: Machines are usually designed for mass production, making them less ideal for small-order projects or frequent design changes.

- Maintenance: Requires more frequent maintenance.

- Yarn unroving: Yarn cannot be unroved from the fabric edges.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.