Podcast

Questions and Answers

What is the primary function of warp beams in the construction of warp knitted fabrics?

What is the primary function of warp beams in the construction of warp knitted fabrics?

- To create patterns in the fabric

- To regulate the temperature of the yarn

- To hold the guide bars in place

- To ensure uniform conditions of warp feed and tension (correct)

Which element is essential for producing commercially acceptable warp knitted structures?

Which element is essential for producing commercially acceptable warp knitted structures?

- At least two guide bars and two warp sheets (correct)

- Three guide bars and one warp sheet

- One guide bar and one warp sheet

- Two guide bars and two warp sheets

What is the purpose of warp guides in the warp knitting process?

What is the purpose of warp guides in the warp knitting process?

- To strengthen the fabric

- To thread yarn ends from the warp sheets (correct)

- To control the color patterns in the fabric

- To adjust the speed of the knitting machine

How does yarn tension affect the operation of raschel machines?

How does yarn tension affect the operation of raschel machines?

Which aspect differentiates the take-down system of a warp knitting machine from that of a weft knitting machine?

Which aspect differentiates the take-down system of a warp knitting machine from that of a weft knitting machine?

What is the typical capacity of modern warp beams in terms of warp length?

What is the typical capacity of modern warp beams in terms of warp length?

What role does the guide bar serve in the warp knitting process?

What role does the guide bar serve in the warp knitting process?

What happens to the fabric during the take-down process on a warp knitting machine?

What happens to the fabric during the take-down process on a warp knitting machine?

What is the purpose of using multiple beams attached to a beam shaft in warp knitting?

What is the purpose of using multiple beams attached to a beam shaft in warp knitting?

Which statement best describes the function of the guide bars in warp knitting?

Which statement best describes the function of the guide bars in warp knitting?

How does modern yarn feeding technology typically function in warp knitting?

How does modern yarn feeding technology typically function in warp knitting?

What is one advantage of the take-down system in a warp knitting machine compared to a weft knitting machine?

What is one advantage of the take-down system in a warp knitting machine compared to a weft knitting machine?

What is typically the minimum number of guide bars required for commercially acceptable warp knitted structures?

What is typically the minimum number of guide bars required for commercially acceptable warp knitted structures?

How are the warp guides designed for warp knitting machines?

How are the warp guides designed for warp knitting machines?

What defines the lapping movement in the construction of warp knitted fabrics?

What defines the lapping movement in the construction of warp knitted fabrics?

What key feature is associated with yarn feeding in the context of warp knitting technology?

What key feature is associated with yarn feeding in the context of warp knitting technology?

Flashcards

Warp beam

Warp beam

A flanged beam holding yarn ends, supplying yarn for warp knitting with uniform tension.

Guide bar

Guide bar

A device that directs yarn ends for consistent lapping movements in warp knitting.

Warp guides

Warp guides

Metal plates that hold and space yarn ends, ensuring proper placement in warp knitting.

Yarn feeding technology

Yarn feeding technology

Signup and view all the flashcards

Take-down system

Take-down system

Signup and view all the flashcards

Warp knitting structure

Warp knitting structure

Signup and view all the flashcards

Warp sheet

Warp sheet

Signup and view all the flashcards

Warp beams

Warp beams

Signup and view all the flashcards

Warp Beam Purpose

Warp Beam Purpose

Signup and view all the flashcards

Guide Bar Function

Guide Bar Function

Signup and view all the flashcards

Warp Guide Role

Warp Guide Role

Signup and view all the flashcards

Warp Tension Control

Warp Tension Control

Signup and view all the flashcards

Take-down System Function

Take-down System Function

Signup and view all the flashcards

Minimum Guide Bars

Minimum Guide Bars

Signup and view all the flashcards

Study Notes

Warp Knitting Machine

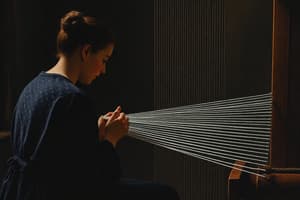

- Warp knitting involves a structure where yarns from a single warp sheet are used creating the fabric.

- The yarns (ends) share identical lapping movements guided by a bar and its attached guides.

Basics of Warp Knitting

-

Construction of warp knitted fabrics: All yarn ends are supplied from one warp sheet and share identical overlapping movements. Each yarn is guided by a specific guide attached to the same guide bar.

-

Warp beams: These beams ensure uniform yarn feed and tension. Flanged beams, attached to shafts, unwind the warp sheet in a parallel formation. Multiple beams can be used to create a wider warp sheet.

- For example, an 84-inch wide warp sheet can be created by using two 42-inch wide beams or four 21-inch wide beams.

-

Guide bar: Each guide bar is provided with a warp sheet from its own beam shaft, suitable to the bar's threading, and warp feed rate. The minimum number of guide bars and warp sheets for commercially viable structures is usually two.

-

Guides: Thin metal plates with a lower hole for threading yarn ends if required. Guide plates are grouped, fastened at their upper ends to a metal lead, and spaced similarly to needles.

-

Yarn feeding technology: Yarn is fed to the needles from the warp beam, the pitch of yarn spacing matching the machine gauge. Modern warp beams carry 30,000 to 50,000 meters of yarn.

- On earlier and some modern machines, the yarn tension from the needles is used to manage yarn on larger warp systems. A warp brake or let-off system helps control this yarn tension.

-

Take-down technology: Relatively simpler than weft knitting machines. The fabric is pulled through a nip created by two or three rollers driven by a gear train or chains, connected to the machine's main shaft. Roller 1 is the main, driven roller. Roller 2 presses against roller 1 via a spring, to stop slippage. Fabric is then wound up on another fabric roller.

Warp Knitting Machines (Types)

- Tricot machine

- Compound needle warp knitting machine

- Raschel machine

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.