Podcast

Questions and Answers

¿Cuál es la función principal de la bancada en un torno a torno?

¿Cuál es la función principal de la bancada en un torno a torno?

- Girar la pieza de trabajo entre centros

- Albergar herramientas de perforación y taladrado

- Sujetar firmemente el material durante el proceso de corte (correct)

- Realizar la operación de conformado

¿Qué parte del torno a torno contiene las herramientas de perforación o taladrado?

¿Qué parte del torno a torno contiene las herramientas de perforación o taladrado?

- El plato giratorio

- El cabezal

- El husillo (correct)

- El contrapunto

¿Qué tipo de operación realiza el torno a torno durante el proceso de torneado?

¿Qué tipo de operación realiza el torno a torno durante el proceso de torneado?

- Inyectar material para formar una pieza

- Eliminar material en forma de virutas (correct)

- Soldar piezas metálicas

- Pulir la superficie de la pieza

¿En qué industrias es comúnmente utilizado el torno a torno?

¿En qué industrias es comúnmente utilizado el torno a torno?

¿Qué tipo de torno es una versión más grande y robusta del torno de banco para operaciones en talleres o garajes pequeños?

¿Qué tipo de torno es una versión más grande y robusta del torno de banco para operaciones en talleres o garajes pequeños?

¿Qué característica define a un torno a torno como un torno motorizado utilizado principalmente para operaciones de torneado con velocidades reducidas?

¿Qué característica define a un torno a torno como un torno motorizado utilizado principalmente para operaciones de torneado con velocidades reducidas?

Flashcards are hidden until you start studying

Study Notes

Torno

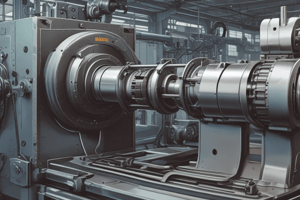

A torno is a type of lathe machine used for shaping materials such as wood, metal, or plastic. It consists of two main parts: the bed and the spindle. The bed is the base where the material is clamped and held firm during the cutting process. The spindle is the part with various drilling or boring tools attached which perform the actual shaping operation.

The turning process involves rotating the workpiece between centers while a cutting tool is fed into it from another direction, typically perpendicular, to remove material in the form of chips. This process can be used to create precise cuts, holes, threads, and other features on cylindrical or conical surfaces.

Tornos are commonly used in industries such as automotive manufacturing, furniture making, and general machining. They are known for their versatility and ability to produce high-quality components or products efficiently.

There are different types of tornos based on the size and complexity of the work they can handle:

- Engine lathes: These are small benchtop machines used mainly for turning operations with greatly reduced speeds compared to larger lathes.

- Machine shop lathes: Larger versions of engine lathes designed specifically for small independent machine shops or garages.

- Centre-lathes (or vertical lathes): These are heavy-duty lathes capable of handling large, heavy workpieces.

- Turning centres (or CNC lathes): These are computer-controlled lathes that allow for faster production with minimal human intervention.

- Special purpose lathes: These include special forms of centre lathes adapted to specific tasks, like the spline and taper lathe.

Despite their widespread use, tornos also require skilled operators to achieve the best results. The process involves setting up the machine, clamping the workpiece, loading the cutting tool, and adjusting the cutting parameters.

In conclusion, tornos are essential tools in industries that require precision and efficiency in shaping materials. Their versatility and ability to produce high-quality components have made them indispensable in various sectors, from automotive manufacturing to furniture making.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.