Podcast

Questions and Answers

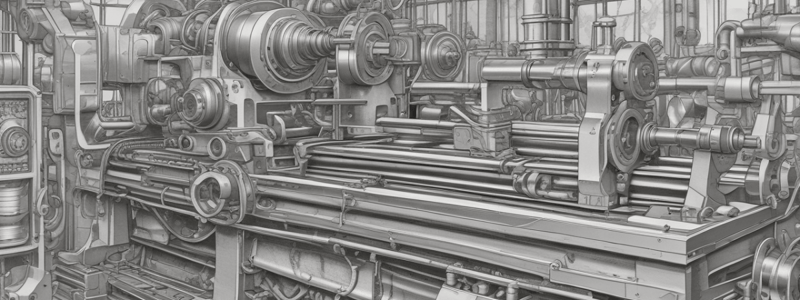

What is the main function of a lathe machine?

What is the main function of a lathe machine?

- To measure the dimensions of the work piece

- To shape metal using heat treatment

- To remove material from a work piece to produce the required shape and size (correct)

- To weld pieces together

Who is credited with designing the first screw cutting lathe?

Who is credited with designing the first screw cutting lathe?

- Isaac Newton

- Leonardo da Vinci

- Henry Maudslay (correct)

- Alexander Graham Bell

Which type of lathe occupies less floor space?

Which type of lathe occupies less floor space?

- Horizontal lathe

- Facing lathe

- Vertical lathe (correct)

- Roll turning lathe

What does a single purpose lathe typically do?

What does a single purpose lathe typically do?

What was the significance of Egyptian tree lathes in the history of lathes?

What was the significance of Egyptian tree lathes in the history of lathes?

Why is a single point cutting tool generally used in lathes?

Why is a single point cutting tool generally used in lathes?

What is the primary function of the headstock in a centre lathe?

What is the primary function of the headstock in a centre lathe?

In a centre lathe, what is the function of the tailstock?

In a centre lathe, what is the function of the tailstock?

Which lathe type is suitable for fast and mass production of small size and simple shaped jobs?

Which lathe type is suitable for fast and mass production of small size and simple shaped jobs?

What distinguishes flexible automation lathes from fixed automation lathes?

What distinguishes flexible automation lathes from fixed automation lathes?

Which part of a centre lathe supports the cross slide, compound rest, and tool post?

Which part of a centre lathe supports the cross slide, compound rest, and tool post?

What is the primary function of the carriage in a centre lathe?

What is the primary function of the carriage in a centre lathe?

Which type of lathe is suitable for holding slender rod-like jobs in collets?

Which type of lathe is suitable for holding slender rod-like jobs in collets?

What distinguishes semi-automatic lathes from non-automatic lathes?

What distinguishes semi-automatic lathes from non-automatic lathes?

Which part in a centre lathe can be moved by hand or given power feed through apron mechanism?

Which part in a centre lathe can be moved by hand or given power feed through apron mechanism?

What distinguishes precision lathes from ordinary lathes?

What distinguishes precision lathes from ordinary lathes?

What is the term used for the lower part of the carriage that contains gears, clutches, and levers?

What is the term used for the lower part of the carriage that contains gears, clutches, and levers?

In a lathe, what is the term for the movement of the tool relative to the work piece?

In a lathe, what is the term for the movement of the tool relative to the work piece?

Which feed type involves the tool moving parallel to the axis of the lathe?

Which feed type involves the tool moving parallel to the axis of the lathe?

What mechanism is used to move the carriage or cross-slide for various operations except thread cutting?

What mechanism is used to move the carriage or cross-slide for various operations except thread cutting?

When is the lead screw brought into operation in a lathe?

When is the lead screw brought into operation in a lathe?

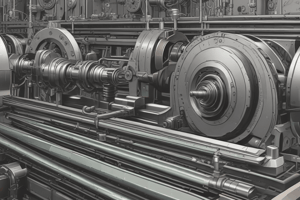

Which motion in lathes is attained by rotating the job?

Which motion in lathes is attained by rotating the job?

How does the cutting tool derive its automatic feed motion in a lathe?

How does the cutting tool derive its automatic feed motion in a lathe?

Which mechanism is used to change the feed rate in a lathe as needed?

Which mechanism is used to change the feed rate in a lathe as needed?

What type of headstock driving mechanism is used to reduce spindle speed for thread cutting?

What type of headstock driving mechanism is used to reduce spindle speed for thread cutting?

What is used to positively cause travel of the carriage during screw threading in a lathe?

What is used to positively cause travel of the carriage during screw threading in a lathe?

What is the purpose of the quick-change gearbox in the lathe?

What is the purpose of the quick-change gearbox in the lathe?

How many different speeds can Shaft C receive in the quick-change gearbox?

How many different speeds can Shaft C receive in the quick-change gearbox?

In the tumbler gear quick-change gearbox, how are various speeds obtained?

In the tumbler gear quick-change gearbox, how are various speeds obtained?

What is the function of the apron mechanism in the lathe?

What is the function of the apron mechanism in the lathe?

How does the splined shaft in the apron mechanism function?

How does the splined shaft in the apron mechanism function?

What happens when the feed check knob 'E' is in a neutral position?

What happens when the feed check knob 'E' is in a neutral position?

In what direction does the lead screw rotate in relation to the spindle?

In what direction does the lead screw rotate in relation to the spindle?

What is connected to Shaft C in the quick-change gearbox?

What is connected to Shaft C in the quick-change gearbox?

What is attached to Shaft B (Sliding gear shaft) in both gearboxes?

What is attached to Shaft B (Sliding gear shaft) in both gearboxes?

How are different sizes of gears transmitted to Shaft A (Cone gear shaft) in both gearboxes?

How are different sizes of gears transmitted to Shaft A (Cone gear shaft) in both gearboxes?

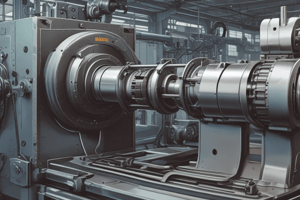

What is the purpose of the back gears B1 and B2 in a lathe?

What is the purpose of the back gears B1 and B2 in a lathe?

Which statement is true about the all geared headstock in modern lathes?

Which statement is true about the all geared headstock in modern lathes?

In a lathe, what is the main function of feed mechanisms?

In a lathe, what is the main function of feed mechanisms?

What happens when the tumbler gear mechanism is shifted to its upward position during lathe operation?

What happens when the tumbler gear mechanism is shifted to its upward position during lathe operation?

Which component in a lathe is responsible for power transmission from motor to spindle through a belt drive?

Which component in a lathe is responsible for power transmission from motor to spindle through a belt drive?

How are different spindle speeds achieved in an all geared headstock in modern lathes?

How are different spindle speeds achieved in an all geared headstock in modern lathes?

What is the advantage of using an all geared headstock compared to a cone pulley mechanism?

What is the advantage of using an all geared headstock compared to a cone pulley mechanism?

'When back gear is not engaged' in a lathe, what type of speed is obtained at the spindle?

'When back gear is not engaged' in a lathe, what type of speed is obtained at the spindle?

What mechanism is used for automatic longitudinal feed in a lathe machine?

What mechanism is used for automatic longitudinal feed in a lathe machine?

How is automatic cross feed achieved in a lathe machine?

How is automatic cross feed achieved in a lathe machine?

Which mechanism allows for the reversal of both longitudinal and cross feed in a lathe machine?

Which mechanism allows for the reversal of both longitudinal and cross feed in a lathe machine?

What is the purpose of using a half nut lever in a lathe machine?

What is the purpose of using a half nut lever in a lathe machine?

Which chuck type is commonly used for holding non-circular bars in a lathe machine?

Which chuck type is commonly used for holding non-circular bars in a lathe machine?

What provides magnetic power to the magnetic chuck in a lathe machine?

What provides magnetic power to the magnetic chuck in a lathe machine?

What is the purpose of drills and reamers when used in the tailstock of a lathe machine?

What is the purpose of drills and reamers when used in the tailstock of a lathe machine?

What is the purpose of using a catch plate or driving plate in a lathe?

What is the purpose of using a catch plate or driving plate in a lathe?

How are carbide, ceramic, and cermet inserts clamped in the tool post?

How are carbide, ceramic, and cermet inserts clamped in the tool post?

Why are mandrels made of high carbon steel?

Why are mandrels made of high carbon steel?

Which type of cutting tool is mainly used for general purpose work in center lathes?

Which type of cutting tool is mainly used for general purpose work in center lathes?

Which type of centre is preferably used to avoid sliding friction between the job and the centre?

Which type of centre is preferably used to avoid sliding friction between the job and the centre?

How are solid tools described in terms of material and manufacturing process?

How are solid tools described in terms of material and manufacturing process?

In a lathe, what is the purpose of a tipped centre?

In a lathe, what is the purpose of a tipped centre?

What is the primary advantage of fastening tips mechanically to a carbon steel shank rather than brazing them?

What is the primary advantage of fastening tips mechanically to a carbon steel shank rather than brazing them?

When holding long slender rods in between live and dead centres, what is used to transmit torque and rotation from the spindle to the job?

When holding long slender rods in between live and dead centres, what is used to transmit torque and rotation from the spindle to the job?

What is the function of a steady rest in a lathe setup?

What is the function of a steady rest in a lathe setup?

In precision boring in a center lathe, where may the boring tool be fitted for support?

In precision boring in a center lathe, where may the boring tool be fitted for support?

What is the main purpose of a follower rest in lathe operations?

What is the main purpose of a follower rest in lathe operations?

Why are ball centres specifically suitable for taper turning?

Why are ball centres specifically suitable for taper turning?

Flashcards are hidden until you start studying