Podcast

Questions and Answers

Which discipline involves calculation of stress and strain in structures and mechanical components?

Which discipline involves calculation of stress and strain in structures and mechanical components?

- Thermodynamics

- Fluid Mechanics

- Strength of Materials (correct)

- Electrical Engineering

In engineering construction, what is a critical consideration for the components of a structure or machine?

In engineering construction, what is a critical consideration for the components of a structure or machine?

- Material color

- Definite physical sizes (correct)

- Surface texture

- Aesthetic appeal

What is the primary purpose of properly proportioning parts in engineering design?

What is the primary purpose of properly proportioning parts in engineering design?

- To resist actual or probable forces (correct)

- To minimize material usage

- To reduce manufacturing costs

- To improve appearance

Which aspects does the subject of strength of materials involve analytical methods for determining?

Which aspects does the subject of strength of materials involve analytical methods for determining?

What fundamental laws primarily govern the equilibrium of forces acting on a member?

What fundamental laws primarily govern the equilibrium of forces acting on a member?

Besides the laws of mechanics, what other characteristics influence the behavior of a member subjected to forces?

Besides the laws of mechanics, what other characteristics influence the behavior of a member subjected to forces?

Which of the following best describes mechanical properties of a material?

Which of the following best describes mechanical properties of a material?

Which of the following is NOT a mechanical property of materials?

Which of the following is NOT a mechanical property of materials?

What material property is defined as the ability to return to its original shape after the removal of an applied load?

What material property is defined as the ability to return to its original shape after the removal of an applied load?

What is defined as the internal force per unit area within a material that arises from externally applied forces?

What is defined as the internal force per unit area within a material that arises from externally applied forces?

What does strain measure?

What does strain measure?

What property describes a material's ability to undergo permanent deformation when subjected to stress beyond its yield point?

What property describes a material's ability to undergo permanent deformation when subjected to stress beyond its yield point?

Which material property indicates its ability to undergo significant plastic deformation before fracture?

Which material property indicates its ability to undergo significant plastic deformation before fracture?

What is the measure of a material's ability to withstand an applied force without failure?

What is the measure of a material's ability to withstand an applied force without failure?

What term defines the ability of a material to absorb energy and deform plastically without fracturing?

What term defines the ability of a material to absorb energy and deform plastically without fracturing?

What is the significance of understanding elasticity and plasticity in materials science?

What is the significance of understanding elasticity and plasticity in materials science?

What is the term for the amount of strain that has been recovered after the removal of applied stress?

What is the term for the amount of strain that has been recovered after the removal of applied stress?

According to Hooke's Law, what is the relationship between deformation and applied stress within the material's elastic limit?

According to Hooke's Law, what is the relationship between deformation and applied stress within the material's elastic limit?

What is the elastic limit of a material?

What is the elastic limit of a material?

Which materials are commonly used when plastic deformation is advantageous?

Which materials are commonly used when plastic deformation is advantageous?

Flashcards

Strength of materials

Strength of materials

The field concerned with calculating stress and strain in structures and mechanical parts.

Strength of materials involves

Strength of materials involves

Analytical methods for determining strength, stiffness (deformation characteristics), and stability of load-carrying members.

Elasticity

Elasticity

A materials ability to return to its original shape after a load is removed.

Stress

Stress

Signup and view all the flashcards

Strain

Strain

Signup and view all the flashcards

Plasticity

Plasticity

Signup and view all the flashcards

Ductility

Ductility

Signup and view all the flashcards

Strength

Strength

Signup and view all the flashcards

Toughness

Toughness

Signup and view all the flashcards

Elastic Strain

Elastic Strain

Signup and view all the flashcards

Elastic Deformation

Elastic Deformation

Signup and view all the flashcards

Elastic Limit

Elastic Limit

Signup and view all the flashcards

Plasticity

Plasticity

Signup and view all the flashcards

Plastic Deformation

Plastic Deformation

Signup and view all the flashcards

Plastic Strain

Plastic Strain

Signup and view all the flashcards

Study Notes

Introduction to Strength of Materials

-

Strength of materials is the study of calculating stress and strain in components

-

In engineering construction, structural components or machines should have specified physical dimensions

-

Parts should be designed to withstand anticipated forces

-

Analytical methods in strength of materials determine:

- Strength

- Stiffness (deformation characteristics)

- Stability of load-bearing members

-

A member's behavior under force depends on:

- Newtonian mechanics laws governing equilibrium

- Mechanical characteristics of the materials used

Mechanical Properties of Materials

-

Mechanical properties affect a material's mechanical strength and moldability

-

Examples of these properties include:

- Elasticity

- Stress

- Strain

- Plasticity

- Ductility

- Strength

- Toughness

-

Elasticity is a material's capacity to return to its original shape.

-

Stress is internal force per unit area caused by external forces.

-

Strain measures deformation as displacement between particles.

-

Plasticity allows permanent deformation beyond the yield point.

-

Ductility measures plastic deformation before fracture; ductile materials can be drawn into wires

-

Strength is the capacity to withstand force without failure.

-

Toughness is the capacity to absorb energy and deform without fracturing, indicating resistance to crack propagation under stress.

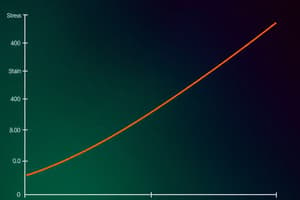

Elasticity and Plasticity Behavior

-

Elasticity and plasticity describe how materials respond to stress and strain.

-

Understanding these behaviors is important in materials science and engineering.

-

Elasticity allows a material to return to its original shape and size after stress is removed.

-

Elastic strain is the amount of strain recovered after stress removal.

-

Elastic Deformation: Material deforms elastically within its elastic limit under external forces.

-

Hooke's Law: Deformation is proportional to stress, given by σ = E⋅ϵ

- σ = stress

- E = modulus of elasticity (Young's Modulus)

- ϵ = strain

-

Elastic Limit: Maximum stress without permanent deformation; beyond this, plastic behavior begins.

-

Elastic materials include metals like steel, polymers at low strains, and rubber.

-

Plasticity enables permanent deformation beyond the elastic limit; the material doesn't return to its original shape after load removal.

-

Plastic Deformation: Occurs when stress exceeds yield strength.

-

Plastic strain is the strain remaining after stress is removed.

-

Ductile materials, like copper, aluminum, and low-carbon steel, are used often for plastic deformation benefits.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.