Podcast

Questions and Answers

What is process analysis?

What is process analysis?

Process analysis utilizes analytical mechanisms to understand the impact of process design on output, cost, or any performance metric.

Which of the following is NOT an issue in process analysis?

Which of the following is NOT an issue in process analysis?

- Not modifying the process (correct)

- Utilization of resources

- Cost of operation

- Adequate resources to meet demand

What does MTS stand for?

What does MTS stand for?

Mass Production Systems

What is the throughput time for the toy manufacturing process?

What is the throughput time for the toy manufacturing process?

Identify the bottleneck in the toy manufacturing process.

Identify the bottleneck in the toy manufacturing process.

What is the cycle time for the toy manufacturing process?

What is the cycle time for the toy manufacturing process?

What is the productive capacity of the toy manufacturing process?

What is the productive capacity of the toy manufacturing process?

What influences the shift of the bottleneck in a process?

What influences the shift of the bottleneck in a process?

The elapsed time from the first stage of the process to the last stage is called ______.

The elapsed time from the first stage of the process to the last stage is called ______.

In continuous processes, a pallet of finished toys comes out every ______ minutes.

In continuous processes, a pallet of finished toys comes out every ______ minutes.

Flashcards are hidden until you start studying

Study Notes

Process Analysis: Definition & Scope

- Process analysis examines how process design impacts output and cost.

- It evaluates alternative configurations based on performance metrics.

Issues in Process Analysis

- Questions addressed include resource adequacy, utilization, capacity increase methods, and operational costs.

- A thorough analysis helps determine optimal resource allocation and performance improvements.

Process Analysis for Make-to-Stock (MTS)

- Relevant queries focus on productive capacity per shift, bottleneck identification, investment stages for capacity increase, and alternative improvement methods without resource addition.

Process Analysis for Make-to-Order (MTO)

- Critical question revolves around the timing of order execution.

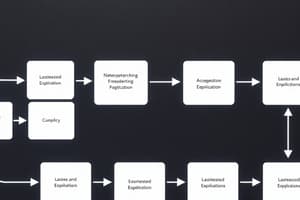

Process Flow Charting

- Begins with identifying activities, time taken for each, and flow of materials/information.

- Utilizes standardized symbols for representation:

- Step in Process

- Transportation

- Storage or Inventory

Toy Manufacturing Process

- Manufacturing flow consists of arranging, pre-treating, painting, drying, and packing toys in distinct steps.

- Total time for the process is 55 minutes: 8 (prepare) + 12 (pre-treat) + 20 (paint) + 10 (dry) + 5 (pack).

Performance Metrics

- Throughput Time (TPUT): Total time from the first to last stage; for the toy process, it's 55 minutes.

- Cycle Time: Time between successive outputs; for this process, it’s 20 minutes.

- Bottleneck: Identified as the spray painting stage, limiting overall output.

Production Capacity Analysis

- Current capacity is 3 pallets/hour (12 toys).

- Daily production over 8 hours yields 24 pallets (96 toys).

- Capacity is unbalanced across various process stages.

Improved Process Considerations

- Introducing two parts in the preparation process (setting up and loading) modifies time requirements.

- Capacity changes with various conditions (e.g., two pre-treatment stations or spraying multiple pallets simultaneously).

Observations on Batch Sizes and Resources

- Batch sizes critically determine bottleneck locations within the process, potentially shifting bottlenecks (wandering bottleneck).

- Resource allocation decisions can significantly alter the efficiency and output of the process.

Summary of Production Capacity under Different Scenarios

- Existing Scenario: Single pallet per cycle, with specific throughput rates.

- Batch size adjustments result in varying processing times and pallet throughput across preparation, pre-treatment, painting, and packing stages.

Conclusion

- Process analysis assists in identifying issues and enhancing overall operations.

- Evaluates how varying resource availability and batch sizes affect production capacity and efficiency.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.