Podcast

Questions and Answers

What are the advantages of powder metallurgy in producing parts?

What are the advantages of powder metallurgy in producing parts?

Parts with closed dimensional tolerance and good surface finish can be produced. It eliminates or minimizes scrap losses by more than 97% of the raw material in the finished part, reduces labor cost by employing unskilled labor through full automation, and facilitates the manufacture of certain parts by mixing different metals, metals and non-metals, metals and ceramics, etc.

What is the production rate range of powder metallurgy?

What is the production rate range of powder metallurgy?

The production rates of powder metallurgy can range from a few hundreds to several thousands of parts per hour.

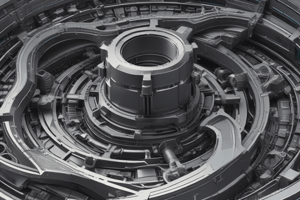

Explain the powder metallurgy process in manufacturing ferrous and nonferrous materials.

Explain the powder metallurgy process in manufacturing ferrous and nonferrous materials.

The powder metallurgy process involves mixing elemental or alloy powder, compacting the mixture in a die, and then sintering or heating the resultant shape in a controlled atmosphere. It is a cost-effective method of manufacturing ferrous and nonferrous materials.

Explain the powder metallurgy process in manufacturing ferrous and nonferrous materials.

Explain the powder metallurgy process in manufacturing ferrous and nonferrous materials.

What is one important feature of powder metallurgy in terms of labor cost?

What is one important feature of powder metallurgy in terms of labor cost?

How does powder metallurgy minimize scrap losses compared to other processes?

How does powder metallurgy minimize scrap losses compared to other processes?

What is the significance of the controlled atmosphere in the powder metallurgy process?

What is the significance of the controlled atmosphere in the powder metallurgy process?

What are the advantages of powder metallurgy in terms of part production?

What are the advantages of powder metallurgy in terms of part production?

Why is powder metallurgy considered a cost-effective method of manufacturing?

Why is powder metallurgy considered a cost-effective method of manufacturing?

How does powder metallurgy facilitate the manufacture of certain parts?

How does powder metallurgy facilitate the manufacture of certain parts?

Flashcards are hidden until you start studying