Podcast

Questions and Answers

Which of the following is an example of a natural polymer?

Which of the following is an example of a natural polymer?

- Neoprene

- Polyamides

- Polyethylene

- Cellulose (correct)

Which process involves the creation of macromolecules from basic units or monomers?

Which process involves the creation of macromolecules from basic units or monomers?

- Plasticization

- Fillers

- Stabilization

- Polymerization (correct)

Which of the following properties makes plastics advantageous compared to steels?

Which of the following properties makes plastics advantageous compared to steels?

- Higher density

- Greater hardness

- Lower weight (correct)

- Superior thermal conductivity

What is a key characteristic of thermosets that distinguishes them from thermoplastics?

What is a key characteristic of thermosets that distinguishes them from thermoplastics?

What is the main purpose of vulcanization?

What is the main purpose of vulcanization?

What components combine to define a plastic material?

What components combine to define a plastic material?

Which of the following monomers is used in addition polymerization to produce polyethylene?

Which of the following monomers is used in addition polymerization to produce polyethylene?

What type of reaction is used to create polyamides (nylon)?

What type of reaction is used to create polyamides (nylon)?

Which term describes a polymer that is synthesized from two different monomers?

Which term describes a polymer that is synthesized from two different monomers?

What is the structural arrangement of polymer chains in an amorphous polymer?

What is the structural arrangement of polymer chains in an amorphous polymer?

Which term describes the arrangement of chiral centers in a polymer macromolecule?

Which term describes the arrangement of chiral centers in a polymer macromolecule?

Which of the following properties is characteristic of amorphous polymers?

Which of the following properties is characteristic of amorphous polymers?

What happens to thermoset polymers when reheated?

What happens to thermoset polymers when reheated?

In polymer processing, what does 'pre-molding' primarily involve?

In polymer processing, what does 'pre-molding' primarily involve?

Which of the following manufacturing processes is typically used for producing continuous, simple geometries in plastics?

Which of the following manufacturing processes is typically used for producing continuous, simple geometries in plastics?

Which of the following is NOT a typical method for forming crosslinks in polymers?

Which of the following is NOT a typical method for forming crosslinks in polymers?

Which category of thermoplastics is generally known for offering the highest price and benefits, often tailored for specialized applications?

Which category of thermoplastics is generally known for offering the highest price and benefits, often tailored for specialized applications?

What characteristic distinguishes semicrystalline polymers from amorphous polymers regarding their thermal behavior?

What characteristic distinguishes semicrystalline polymers from amorphous polymers regarding their thermal behavior?

Why are thermosets preferred over thermoplastics in applications requiring high-temperature resistance?

Why are thermosets preferred over thermoplastics in applications requiring high-temperature resistance?

Which of the following statements about elastomers is correct?

Which of the following statements about elastomers is correct?

What is the primary characteristic that defines isotactic polymers?

What is the primary characteristic that defines isotactic polymers?

Which of the following is a characteristic of 'High Density Polyethylene' (HDPE)?

Which of the following is a characteristic of 'High Density Polyethylene' (HDPE)?

In the context of polyethylene, what effect does an increase in molecular mass have on the material's properties?

In the context of polyethylene, what effect does an increase in molecular mass have on the material's properties?

Which property does Vinyl Acetate confer to Ethylene-Vinyl Acetate (EVA) copolymers?

Which property does Vinyl Acetate confer to Ethylene-Vinyl Acetate (EVA) copolymers?

What is a significant limitation of polyvinyl chloride (PVC) that requires the use of plasticizers?

What is a significant limitation of polyvinyl chloride (PVC) that requires the use of plasticizers?

Which property makes isotactic polypropylene desirable?

Which property makes isotactic polypropylene desirable?

What is a common application enhanced by high transparency and scratch resistance of acrylics?

What is a common application enhanced by high transparency and scratch resistance of acrylics?

Which structural feature of Polyamides effects its properties?

Which structural feature of Polyamides effects its properties?

Which of the statements best explains the characteristics of Semicrystalline structure?

Which of the statements best explains the characteristics of Semicrystalline structure?

Which the best reason for using an isotactic polymer?

Which the best reason for using an isotactic polymer?

How can you impart thermal stability to PVC?

How can you impart thermal stability to PVC?

What are the applications for Polymethylmethacrylate?

What are the applications for Polymethylmethacrylate?

Why are coatings applied to siloxanes

Why are coatings applied to siloxanes

What process is 'in-situ polymerization' used?

What process is 'in-situ polymerization' used?

Which properties are the most important when using Polymetilmethacrylate?

Which properties are the most important when using Polymetilmethacrylate?

Which property does Vinyl Acetate confer to Ethylene Vinyl Acetate copolymers?

Which property does Vinyl Acetate confer to Ethylene Vinyl Acetate copolymers?

Which method is likely applied to making PLA?

Which method is likely applied to making PLA?

What can high grade polyesters be used for?

What can high grade polyesters be used for?

What negative property can be found in HIGH impact polystyrene?

What negative property can be found in HIGH impact polystyrene?

Why are additives commonly added to polymers?

Why are additives commonly added to polymers?

What kind of product is bakelite?

What kind of product is bakelite?

Flashcards

What are Polymers?

What are Polymers?

Large molecules made of repeating structural units (monomers), both natural and synthetic.

What are Natural Polymers?

What are Natural Polymers?

Polymers derived from natural sources like cellulose, starch, or rubber.

What are Synthetic Polymers?

What are Synthetic Polymers?

Polymers synthesized from chemical processes.

What are Plastics?

What are Plastics?

Signup and view all the flashcards

What are Fibers?

What are Fibers?

Signup and view all the flashcards

What are Elastomers?

What are Elastomers?

Signup and view all the flashcards

What are Thermoplastics?

What are Thermoplastics?

Signup and view all the flashcards

What are Thermosets?

What are Thermosets?

Signup and view all the flashcards

What is Polymerization?

What is Polymerization?

Signup and view all the flashcards

What are Monomers?

What are Monomers?

Signup and view all the flashcards

What are Macromolecules?

What are Macromolecules?

Signup and view all the flashcards

What are Plasticizers?

What are Plasticizers?

Signup and view all the flashcards

What are Additives?

What are Additives?

Signup and view all the flashcards

What are Fillers?

What are Fillers?

Signup and view all the flashcards

What are Stabilizers?

What are Stabilizers?

Signup and view all the flashcards

What is Polymerization by Addition?

What is Polymerization by Addition?

Signup and view all the flashcards

What is Polymerization by Condensation?

What is Polymerization by Condensation?

Signup and view all the flashcards

What are Copolymers?

What are Copolymers?

Signup and view all the flashcards

What is Random Copolymer?

What is Random Copolymer?

Signup and view all the flashcards

What is Alternant Copolymer?

What is Alternant Copolymer?

Signup and view all the flashcards

What is Block Copolymer?

What is Block Copolymer?

Signup and view all the flashcards

What is Graft Copolymer?

What is Graft Copolymer?

Signup and view all the flashcards

What is Amorphous Structure?

What is Amorphous Structure?

Signup and view all the flashcards

What is Semicrystalline Structure?

What is Semicrystalline Structure?

Signup and view all the flashcards

What are Lamellae?

What are Lamellae?

Signup and view all the flashcards

What are Spherulites?

What are Spherulites?

Signup and view all the flashcards

What is Molecular Architecture?

What is Molecular Architecture?

Signup and view all the flashcards

What is Tacticity?

What is Tacticity?

Signup and view all the flashcards

What is Isotactic Polymer?

What is Isotactic Polymer?

Signup and view all the flashcards

What is Syndiotactic Polymer?

What is Syndiotactic Polymer?

Signup and view all the flashcards

What is Atactic Polymer?

What is Atactic Polymer?

Signup and view all the flashcards

What is the Glass Transition Temperature(Tg)?

What is the Glass Transition Temperature(Tg)?

Signup and view all the flashcards

What is Molding?

What is Molding?

Signup and view all the flashcards

What is Crosslinking?

What is Crosslinking?

Signup and view all the flashcards

What are Reticulated Polymers?

What are Reticulated Polymers?

Signup and view all the flashcards

What are Thermoplastics Classifications?

What are Thermoplastics Classifications?

Signup and view all the flashcards

What are Commodity Thermoplastics?

What are Commodity Thermoplastics?

Signup and view all the flashcards

What are Engineering Thermoplastics?

What are Engineering Thermoplastics?

Signup and view all the flashcards

What are Specialty Thermoplastics?

What are Specialty Thermoplastics?

Signup and view all the flashcards

Study Notes

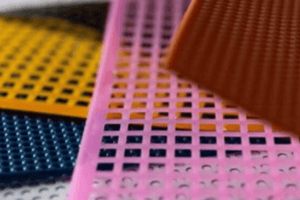

Polymer Classifications

- Polymers are broadly classified into natural and synthetic types.

- Natural polymers include cellulose, starch, and rubber.

- Synthetic polymers are further divided into plastics, fibers, and elastomers.

- Plastics include thermoplastics like polyethylene and thermosets like bakelite.

- Fibers consist of polyamides and polyester.

- Elastomers include neoprene.

Polymer Fabrication and Processing

- Polymers are created through a polymerization process, linking basic units or monomers into macromolecules.

- The resulting high molecular weight polymers can be processed into rubbers, plastics, fibers, adhesives, and coatings.

- Additives such as plasticizers, stabilizers, and fillers are used in polymer processing.

Advantages of Plastics

- Plastics have a low weight, with a density approximately 10% that of steel.

- Plastics are environmentally efficient, requiring less than 30% of the processing energy needed for metals.

- Plastics enable the fabrication of parts with complex geometries and the adaptation of properties to production requirements.

- Plastics are thermal and electrical insulators, and exhibit corrosion and chemical resistance.

- Plastics can be colored and transparent with a controllable friction coefficient.

- Plastics allow for large manufacturing quantities and display elasticity.

- Global consumption of plastics polymers is 200,000,000 tons.

- Global consumption of steels is 1,000 tons.

Polymer Pricing

- Engineering materials' prices vary widely.

- Petroleum-based fuels and construction materials like glass, structural steel, bricks, and concrete are the least expensive.

- Polymers, technical ceramics, and glasses have mid-range prices.

- Exotic materials like diamond, platinum, gold, sapphire, iridium, and beryllium are the most expensive.

- Manufactured products also range in price from inexpensive construction materials to extremely costly items.

Thomas Hancock & Charles Goodyear

- Thomas Hancock and Charles Goodyear patented vulcanization in their respective countries during the 19th century.

- Vulcanization involves adding sulfur to latex in a liquid state ensuring it retains elasticity during processing.

Plastic Composition

- Plastics consist of polymers and additives.

- Polymers are macromolecules, "many parts"

- Every pearl constitutes a repetitive unit formed by one or more monomers

Polymerization Types

- Polymers are obtained through polymerization, with two primary methods: addition and condensation.

- Addition polymerization is exemplified by polyethylene from ethylene monomers expressed as CH2=CH2, forming a chain structure.

- Condensation polymerization is exemplified by polyamides (nylon) from diamines and diacids, with a byproduct of H2O.

Copolymers Composition

- Copolymers are synthesized from two monomers that react with each other instead of forming separate polymers.

- An example is ethylene-propylene copolymer.

- Copolymers can be random, alternant, block, or graft copolymers depending on the arrangement of the monomers.

Polymer Structure

- Polymer structures can be amorphous, resembling clews, or semicrystalline.

- Semycristalline structures can be lamela or spherulite

Molecular Architecture

- Molecular architecture includes linear, branched, and reticulated structures.

- Tacticity, or the stereochemical arrangement in chiral centers, is key.

- IUPAC defines tacticity as macromolecules with constant repeating unit configurations.

- Ordered structures can be isotactic or syndiotactic and tend to crystallize in regular structures.

- Atactic structures tend to be amorphous, which results in lower densities, are easily deformed, offer low stiffness, poor chemical/heat resistant, and low processing temperatures due to low packing.

Thermal Transitions in Thermoplastic Polymers

- Amorphous polymers exhibit a glass transition temperature (Tg) and a decomposition temperature (TD).

- Semicrystalline polymers show a glass transition temp, a crystalline melting point (Tm), and a decomposition temp.

- The state of aggregation and temperature determine final system behavior.

Transformation Processes

- Transformation involves pre-molding, molding, and shape stabilization.

- Pre-molding transports heat to high fluidity.

- Molding flows material through shaping tools.

- Shape stabilization treatment achieves permanent dimensions.

Methods of Transformation

- Continuous methods, such as extrusion, are used for simple geometries.

- Cyclic methods, like injection molding and thermoforming, are employed for complex geometries.

Crosslink Formation

- Crosslinks are formed when the crosslinking (heat) has been promoted.

- Chains have reactive points like double bonds.

- Primary links can form "Direct" between segments or go through bridges by reactive substances like sulfur and styrene monomer.

Thermoplastics Classifications

- Thermoplastics are classified based on price and benefits as well as consumer volume.

- Categories include "Commodities", "Engineering", and "Specials".

- "Commodities" such as PS and PVC tend to be amorphous, as LDPE and HDPE tend to be semicrystalline.

- Engineering plastics include PC, PPO/PS, ASA, SMA, ABS, PMMA, PET, AND EVOH

- Special plastics Include PI, PEEK, PPS, PTFE, PEI, PA11, PES and PA12

Characteristics of Amorphous vs Semicrystalline Thermoplastics

- Amorphous thermoplastics offer are have less heat resistance, a softening range, and are transparent.

- Amorphous thermoplastics offer less shrinkage during cooling, more tenacity at low temp, less dimensional stability, poor fatigue strength, and high creep.

- Semicrystalline thermoplastics have more heat resistance, a punctual fusion temperature, are opaque, greater shrinkage during cooling.

- Semicrystalline thermoplastics offer low toughness at low temp, higher dimensional stability, and are more resistant to fatigue and wear with lower creep.

Thermoplastic Polymers

- Acrylonitrile-butadiene-styrene (ABS)

- Cellulose Ionomers Polyamides (Nylon, PA)

- Polycarbonate (PC)

- Polyethetherketone (PEEK)

- Polyethylene (PE)

- Polymethylmethacrylate (PMMA)

- Polyoxymethylen (POM)

- Polypropylene (PP)

- Polystyrene (PS)

- Polytetrafluoroethylene (PTFE)

- Polyvinylchloride (PVC)

- Polyurethane (PU)

- Polyester (PET, PETE, PBT)

Types of Plastics

- Thermosets are resins that polymerize when catalyzed and heated, and degrade instead of softening when reheated.

- The first commercial thermoset was bakelite, the phenolic resin which offer greater dimensional stability than thermoplastics.

- Thermosets are used in applications needing high-temperature resistance and creep resistance and can be hard, rigid, flexible, or soft.

Thermoset Polymers

- Epoxy

- Phenolics

- Polyester

- Polyurethane

- Polychlorinated

Elastomers Properties

- Elastomers can lengthen, compress, and flex and return to their original shape when the load is finished.

- Elastomers are easy to foam

Elastomers Types

- Acrylic elastomers Chlorinated Elastomers (Neoprene)

- Ethylene-Propylene (EPDM)

- Ethylene-vinyl acetate (EVA)

- Fluorocarbon elastomers (Viton)

- Isoprene Natural rubber Nitrile (NBR, BUNA-N)

- Polybutadiene elastomers Silicone Styrene Butadiene (SBS)

- Thermoplastic elastomers (ΤΡΕ, ΤΡΟ)

World Plastic Consumption (2010)

- Europe consumed 24%

- USA consumed 23%

- Japan consumed 23%

- China consumed 11%

- Taiwan consumed 8%

- Korea consumed 5%

- Russia consumed 3%

- Other countries consumed 3%

Plastic Transformation in Mexico (2008)

- Injection molding made up 34%

- Extrusion made up 30%

- Blowing made up 15%

- Laminated made up 6%

- Rotomolding made up 4%

- Foaming made up 4%

- Compression made up 2%

- Others made up 5%

Top 5 Polymers Consumers

- Ethylene (tpPE, elPE, HDPE, TPO, Mixes PE/PP, foam PE, fiber PE, PP, PP foam, LDPE, EPDM, LLDPE, CPE, PP mixes, PP fiber, VLDPE, EVA, lonomers)

- Styrene (tpPS, elPS, foam PS, mixes PS, ABS, SAN, ASA, ABS mixes, ABS foams, HIPS, SEBS, SBR)

- Chlorinated Vynil (elPVC, tpPVC)

- Urethane (PU foam, tsPU, tpPU) Esters (tpPolyester, tsPolyester, elPolyester Polyester fiber, PET, UP, TPEs, PBT PETE)

Global Consumption of Polymers by Type

- Packaging is a major consumer by %, and contains PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

- Building and Construction makes up 19.7% of global use in the form of PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

- Automotive makes up 10% of global use in the form of PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

- Electrical and Electronic makes up 6.2% of global use in the form of PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

- Agriculture makes up 3.3% of global use in the form of PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

- Household, Leisure & Sports makes up 4.2% of global use in the form of PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

- Others Industries Makes up 16.7% of global use in the form of PE-LD, PE-LLD, PE-HD, PE-MD, PP, PS, PS-E, PVC, PET, ABS, SAN, PMMA, PA, PC, Other ETP, PUR, and Other plastics.

Polyolefins - Poliethylene (PE)

- Polyolefins which are mostly semicrystallines are made from Polyethylene (PE)

- Has a Tg of -120ºC

- LDPE: Low-density polyethylene or high pressure (r = [0.914 - 0.94 g/cm³]), branched showing low crystallinity with 40 to 45% yielding T m = 110 – 112 ºC and T c = 96 - 100 ºC

- HDPE: High-density polyethylene or low pressure( r = [0.96 - 0.97 g/cm³]), Linear with few and short branches with high crystallinity with 60 to 80 % yielding Tm = 130 – 135 ºC and Tc = 118 - 120 ºC

Effect of Molecular Mass on Polyethylene

- When Number of -(CH2-CH2)- unites is 1 then MW is 30 g/mol, Softening temperature is -169 and state is Gas

- When Number of -(CH2-CH2)- unites is 6 then MW is 170 g/mol, Softening temperature is -12 and state is Liquid

- When Number of -(CH2-CH2)- unites is 35 then MW is 1,000 g/mol, Softening temperature is 37 and state is Grease

- When Number of -(CH2-CH2)- unites is 140 then MW is 4,000 g/mol, Softening temperature is 93 and state is Wax

- When Number of -(CH2-CH2)- unites is 250 then MW is 7,000 g/mol, Softening temperature is 98 and state is Hard wax

- When Number of -(CH2-CH2)- unites is 430 then MW is 12,000 g/mol, Softening temperature is 104 and state is Hard resin

- When Number of -(CH2-CH2)- unites is 750 then MW is 21,000 g/mol, Softening temperature is 110 and state is Hard resin

- When Number of -(CH2-CH2)- unites is 1,350 then MW is 38,000 g/mol, Softening temperature is 112 and state is Hard resin

- The change from Hard Wax through to hard resin is defined as when it turns from plastic to polymer.

Polyolefins - Linear Low Density or Low Pressure Polyethylene (LLDPE)

- Polyolefins which are of a commodity are made from Linear Low Density or Low Pressure Polyethylene with a p = [0.94 - 0.96 g/cm³]

- Are typically branched (Short and regular) Medium crystallinity: 45 a 50%

- Stereospecific (Ziegler – Natta, ZN) or “One site” (Metallocenic, Met) is added

- With a structure of CH2= CH2 with + catalyzer yielding C2= CH- (CH2)n- CH3 yielding n= 5,7,9

- Showing a Tm = 115 – 120 ºC

- and T c = 105 -110 ºC

Polyolefins - Polypropylene (PP)

- Polyolefins are commodities which are a made from Polypropylene (PP) which is -(-CH2-CH-)- with a by product of CH3 Yielding a p = [0.895 - 0.92 g/cm³] a Tg = -10ºC, * T m = 165 ºC andT c = 120 ºC Showing an Isotactic orientation → Crystallinity: 60 a 70 %

- Is combined with Ethylene to reduce "unstable tear" problems giving a high impact resistance for a wider T (mínimum) service range

- Shows various orientations of Block compolymer or Random copolymer

Polyolefins (Copolymers)

- Polyolefines can be made with copolymer such as ETHYLENE - VYNIL ACETATE(EVA) with a structure of (-CH2-CH2-)n- combined yielding a (-CH2-CH-)m-

- Vinyl Acetate lends confers flexibility and reduces crystallinity 1 – 10 % mol de VA More rigid 30 - 40 % mol de VA Adhesive

- ETHYLENE - VYNIL ALCOHOL (EVOH)

- (-CH2-CH2-)n- and gives a structure of (-CH2-CH-)m-, is Semicrystalline regardless of VOH content a High barrier to 02 (Molecular "auto-association" by H2 bridge) Showing a Tg = 60 ºC and Tm = 185 a 200 ºC , typically High barrier to 02 and is Hydrophilic!!!!! (absorbs humidity)

Hallogenated Plastics

-

Are commodities that display a POLYVYNILCHLORIDE (PVC) and a Semicrystalline structure and show a structure of -(-CH2-CH-)- a with a 8 Tg = 80 ºC and a * Tm = 230 ºC Thermal UNSTABLE(TD 80 -90ºC) producing HCI Which is typically Rigid and fragile with plasticizers which catalyze degradation

-

Special Hallogenated plastics includes VINYLIDENE POLYCHLORIDE (PVDC) with has a -(-CH-CH-)- chain, is More termal stable, Hard to process, Excellent gas barrier

Styrene Plastics

- A commodity are POLYa STYRENE (PS) , is Transparent, UV sensible and Very fragile! Structure shows -(-CH2-CH-)- a with a Tg = 100 ºC Polyexpan can be created with Polystyrene (emulsión grade) which is Expanded (PS + n-pentano (volatile) And for a More durable and long use plastic HIGH IMPACT POLYSTYRENE (HIPS) has a High impact resistance and is still Opaque! has -(-CH2-CH-)n-(CH2-CH=CH-CH2-)n-

Styrene Copolymers

- Are of commodity – engineering grade in the form of ABS (Acrylonitrile-Butadiene-Styrene) with -(-CH2-CH-)n-(CH2-CH=CH-CH2-)n- -(-CH2-CH-)- shown

- A is Acrilonitrile, B-S is Butadiene & Styrene

- And with added components in the form ofSAN (Styrene- Acrylonitrile): with -(-CH2-CH-)−(-CH2-CH-)n- And can be modified into MBS (Methacrylate-Butadiene-Styrene), ASA (Acrilonitrile-Styrene-Ethyl Acrylate) with shown -(-CH2-CH-)- S-A , also -(-CH2-C-)- with added modifiers

Polyamides

- Polyamides are an engineering grade plastic shown as Vía 1 or Via 2

Acrylic Enginnering

- Is an engineering grade acrylic compound displayed showing various structires

- and the following grades of "Casting" or "in-situ polymerization" grades

- And is an addition of Monomer + initiator in the mold (mass) as well as "Prepolymer" + initiator in the mold which produces a T (exothermic reaction) and T volumetric contraction

- Showing a Molecular mass (Mn = 106) and Very low fluidity (impracticable) which yields Atactic > 37, Sindiotactic > 54% and Isotactic > 9%

Engyneering and solar radiation resistant acrylics

- Tranparent to UV solar radiation which shows High resistance to Photodegradation!

- And as a result shows a Refraction index of 1,492 which is high in comparision to 1,59 of (PS)

- Independent from time

- Aslo shows a Critical angle for total internal reflection in the 42 ° Air-PMMA interface All enabling the development or OOTIC FIBERS In contrast it shows a Low resistance to "Scratch" Which shows a limited utilization in use of car headlights because possible limitation in the use of car headlights has been developed which helps mitigatates the problem of Coating with siloxanes

Acrylics PMMA

Copolymers MMA – Butyl Acrylate and PMMA / Polymethacrylate (PBA) mixtures Show higher transparency that in turn makes them not very sensitive to UV - The material is quite brittle - "Casting" grade (MMA polymerizes during forming) enabling Optical applications (high purity) with ASA

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.