Podcast

Questions and Answers

What is the main service function of plant maintenance?

What is the main service function of plant maintenance?

To maintain and increase the operational efficiency of plant facilities.

Which of the following is NOT an example of equipment or machine failure on the production floor?

Which of the following is NOT an example of equipment or machine failure on the production floor?

- Worn out bearing

- Power failure in office

- Brake failure in vehicles (correct)

- Pressure leaks

The general aim of plant maintenance is to create a safe working environment for workers.

The general aim of plant maintenance is to create a safe working environment for workers.

True (A)

Which of these is a reason why maintenance objectives must be consistent with production goals?

Which of these is a reason why maintenance objectives must be consistent with production goals?

Maintenance problems can arise from _____ due to lack of management attention.

Maintenance problems can arise from _____ due to lack of management attention.

What types of maintenance are classified based on time span?

What types of maintenance are classified based on time span?

What is the disadvantage of corrective maintenance?

What is the disadvantage of corrective maintenance?

Name one area of maintenance discussed in the content?

Name one area of maintenance discussed in the content?

Preventive maintenance occurs when there is a work stoppage due to machine breakdown.

Preventive maintenance occurs when there is a work stoppage due to machine breakdown.

Study Notes

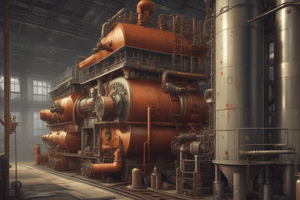

Plant Maintenance Overview

- Plant maintenance is a vital service for an efficient production system.

- It helps maintain and increase the operational efficiency of plant facilities.

- Maintenance focuses on identifying and resolving faults in equipment and machines.

- It can be conducted before or after a breakdown.

- The goal of plant maintenance is to create a productive and safe work environment.

Failure

- A failure occurs when an equipment or machine cannot operate correctly.

- Failure can happen due to various reasons, including worn-out bearings, pumps, pressure leaks, broken shafts, or overheating.

Maintenance in Service Industries

- Maintenance is essential in various industries:

- Hospitals

- Restaurants

- Transport companies

- Banks

- Hotels and resorts

- Shopping malls / retail

- Gas stations

Maintenance in Manufacturing Companies

- Maintenance is crucial in various manufacturing sectors:

- Electronics

- Automotive

- Petrochemicals

- Refineries

- Furniture

- Ceramics

- Food and beverages

Maintenance Objectives

- Minimize downtime and maximize production.

- Minimize repair time and cost.

- Keep productive assets in working condition.

- Minimize accidents.

- Reduce overall maintenance costs.

- Improve product quality.

Importance of Maintenance

- Ensures reliable service and product quality.

- Prevents equipment failures and costly repairs.

- Helps control costs and minimize downtime.

- Justifies significant investments in machinery.

Maintenance Problems

- Lack of management focus on maintenance.

- Insufficient participation by accounting in cost analysis and reporting.

- Challenges in applying quantitative analysis to maintenance.

- Difficulty in obtaining accurate time and cost estimates for maintenance work.

- Difficulty in measuring maintenance performance.

Factors Contributing to Maintenance Problems

- Lack of written objectives and policies.

- Inadequate budgetary control.

- Insufficient control procedures for work orders and service requests.

- Infrequent use of standards to control maintenance work.

- Absence of cost reports for maintenance planning and control.

Maintenance Objectives (Continued)

- Objectives should align with production goals, including cost, quality, delivery, and safety.

- Objectives must be comprehensive and clearly define responsibilities.

Maintenance Costs

- Include the cost of replacing or repairing equipment.

- Include losses of output due to downtime.

- Include delayed shipments and potential customer dissatisfaction.

- Include scrap and rework due to faulty production.

Areas of Maintenance

- Civil Maintenance: Focuses on building construction and maintenance, maintaining service facilities.

- Mechanical Maintenance: Focuses on maintaining machines, equipment, transport vehicles, compressors, and furnaces.

- Electrical Maintenance: Focuses on maintaining electrical equipment such as generators, transformers, motors, telephone systems, lighting, fans, etc.

Classifying Maintenance Problems

- Mechanical Failure: Includes worn-out bushes and bearings, fatigue of machine members, creep of material at high temperatures, excessive forced vibration, misalignments, etc.

- Thermal Failure: Includes overheating of components, lack of lubrication, inadequate cooling, and electrical insulation failure.

- Chemical Failure: Includes failures caused by corrosive fluids, abrasive particles, and failure of protective linings.

Classifying Maintenance Problems by Time Span

- Short-run Production Problems: Maintenance tasks conducted in a short period, such as hourly, daily, weekly, or monthly.

- Hourly: Inspecting lubrication, coolant levels, and cutting tool sharpness.

- Daily: Cleaning machines, tightening nuts, ensuring proper cooling, inspecting indicators, and making minor adjustments.

- Weekly: Performing major adjustments, lubrication, and tightening of parts.

- Monthly: Checking insulation, corrosion, safety guards, and performing other routine tasks.

Types of Maintenance

- Breakdown Maintenance (Corrective Maintenance): Reactive approach where maintenance is performed after a breakdown occurs. It aims to get equipment back in operation as quickly as possible.

- Preventive Maintenance: Proactive approach where scheduled maintenance tasks are performed to prevent breakdowns and extend equipment lifespan. It involves regular inspections, cleaning, lubrication, and replacing parts before failure.

- Predictive Maintenance: Uses data and monitoring to predict potential failures. It involves analyzing sensor data, vibration analysis, and other techniques to identify impending problems.

- Routine Maintenance: Regularly scheduled maintenance tasks that ensure equipment remains in good working order.

- Planned/Scheduled Maintenance: Maintenance tasks planned in advance and scheduled based on equipment needs and operational requirements.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.

Related Documents

Description

This quiz explores the significance of plant maintenance in various sectors, highlighting its impact on operational efficiency and safety in the workplace. It covers the causes of equipment failures and the importance of maintenance in both service and manufacturing industries. Test your knowledge on maintenance practices and their applications across different environments.