Podcast

Questions and Answers

In the Technology Adoption Cycle, which group is MOST likely to require significant evidence and peer validation before adopting a new technology?

In the Technology Adoption Cycle, which group is MOST likely to require significant evidence and peer validation before adopting a new technology?

- Innovators

- Laggards

- Late Majority (correct)

- Early Adopters

A company is experiencing declining sales and profit margins for one of its products. According to the Product Life Cycle, what is the MOST appropriate strategic focus?

A company is experiencing declining sales and profit margins for one of its products. According to the Product Life Cycle, what is the MOST appropriate strategic focus?

- Expansion into new markets

- Focus on innovation and new features

- Cost-cutting and efficiency improvements (correct)

- Aggressive market penetration

According to the BCG Matrix, which product category represents a high-growth market with low market share, requiring significant investment to potentially become a Star?

According to the BCG Matrix, which product category represents a high-growth market with low market share, requiring significant investment to potentially become a Star?

- Cash Cow

- Question Mark (correct)

- Dog

- Star

Which market research technique is MOST suitable for gathering in-depth qualitative data about customer preferences and opinions on a new product concept?

Which market research technique is MOST suitable for gathering in-depth qualitative data about customer preferences and opinions on a new product concept?

In the New Product Development (NPD) process, what is the PRIMARY purpose of stage gates?

In the New Product Development (NPD) process, what is the PRIMARY purpose of stage gates?

A company has fixed costs of $50,000, a selling price of $25 per unit, and a variable cost of $15 per unit. What is the break-even point in units?

A company has fixed costs of $50,000, a selling price of $25 per unit, and a variable cost of $15 per unit. What is the break-even point in units?

A project has the following cash flows: Year 0: -$100,000, Year 1: $30,000, Year 2: $40,000, Year 3: $50,000. If the discount rate is 10%, what is the Net Present Value (NPV) of the project?

A project has the following cash flows: Year 0: -$100,000, Year 1: $30,000, Year 2: $40,000, Year 3: $50,000. If the discount rate is 10%, what is the Net Present Value (NPV) of the project?

A company determines that the market price for its new product should be $150, and it desires a profit of $30 per unit. Using target costing, what is the MOST the company can spend per unit on production?

A company determines that the market price for its new product should be $150, and it desires a profit of $30 per unit. Using target costing, what is the MOST the company can spend per unit on production?

A manufacturing company is implementing a production strategy where production is initiated only when customer orders are received. Which system are they employing?

A manufacturing company is implementing a production strategy where production is initiated only when customer orders are received. Which system are they employing?

A production line has a step that takes significantly longer than all other steps. According to the Theory of Constraints (TOC), what is the immediate next step after identifying this constraint?

A production line has a step that takes significantly longer than all other steps. According to the Theory of Constraints (TOC), what is the immediate next step after identifying this constraint?

Which lean manufacturing principle focuses on making incremental, continuous improvements to processes?

Which lean manufacturing principle focuses on making incremental, continuous improvements to processes?

A company switched from producing goods based on sales forecasts to producing based on actual customer orders. What competitive advantage is the company most likely to gain directly from this change?

A company switched from producing goods based on sales forecasts to producing based on actual customer orders. What competitive advantage is the company most likely to gain directly from this change?

Which of the following scenarios exemplifies the 'Transportation' waste, as defined in lean manufacturing?

Which of the following scenarios exemplifies the 'Transportation' waste, as defined in lean manufacturing?

What is the primary purpose of implementing Single Minute Exchange of Dies (SMED) in a manufacturing setting?

What is the primary purpose of implementing Single Minute Exchange of Dies (SMED) in a manufacturing setting?

In the context of lean manufacturing, what does Jidoka refer to?

In the context of lean manufacturing, what does Jidoka refer to?

A company is experiencing frequent machine breakdowns, causing significant delays in production. To address this, they form cross-functional teams to investigate the underlying reasons for the failures, rather than just repairing the machines each time. Which lean tool are they applying?

A company is experiencing frequent machine breakdowns, causing significant delays in production. To address this, they form cross-functional teams to investigate the underlying reasons for the failures, rather than just repairing the machines each time. Which lean tool are they applying?

Flashcards

Technology Adoption Cycle

Technology Adoption Cycle

Describes how different groups adopt new technology over time.

Product Life Cycle

Product Life Cycle

Stages a product goes through: Introduction, Growth, Maturity, Decline.

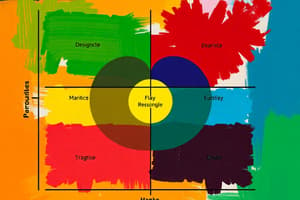

BCG Matrix

BCG Matrix

Classifies products based on market share and growth rate (Stars, Cash Cows, Question Marks, Dogs).

Cycle of Satisfaction

Cycle of Satisfaction

Signup and view all the flashcards

Market Research Techniques

Market Research Techniques

Signup and view all the flashcards

New Product Development (NPD) Process

New Product Development (NPD) Process

Signup and view all the flashcards

Break-even Analysis

Break-even Analysis

Signup and view all the flashcards

Process

Process

Signup and view all the flashcards

Job Shop

Job Shop

Signup and view all the flashcards

Capacity Planning

Capacity Planning

Signup and view all the flashcards

Theory of Constraints (TOC)

Theory of Constraints (TOC)

Signup and view all the flashcards

Process Mapping

Process Mapping

Signup and view all the flashcards

Bottleneck Analysis

Bottleneck Analysis

Signup and view all the flashcards

Lean Management

Lean Management

Signup and view all the flashcards

Pull System

Pull System

Signup and view all the flashcards

5S

5S

Signup and view all the flashcards

Study Notes

- This is an operations management study guide

Technology Adoption Cycle

- Describes how new technology is adopted by different groups over time.

- The adopter categories are innovators, early adopters, early majority, late majority, laggards.

- Key factors influencing adoption are perceived usefulness, ease of use, and social influence.

Product Life Cycle

- The stages are introduction, growth, maturity, and decline.

- Strategic focus shifts from market penetration (early stages) to cost-cutting (maturity and decline).

- Operations implications include capacity planning, inventory management, and process efficiency.

Boston Consulting Group (BCG) Matrix

- Classifies products into stars (high growth, high market share), cash cows (low growth, high market share), question marks (high growth, low market share), and dogs (low growth, low market share).

- Aids in resource allocation and strategic decision-making.

Cycle of Satisfaction

- Ensures customer satisfaction through consistent quality, performance, and service.

- Uses customer feedback loops and continuous improvement.

Market Research Techniques

- Primary research includes surveys, interviews, focus groups, and observations.

- Secondary research includes industry reports, market trends, and competitor analysis.

- Data-driven decision-making enhances product development and positioning.

New Product Development (NPD) Process Including Stage Gates

- Stages include idea generation, concept development, business analysis, product development, market testing, and commercialization.

- Stage Gates evaluate feasibility before proceeding.

Break-even Analysis

- Determines the point at which total revenue equals total costs.

- Break-even Point = Fixed Costs / (Selling Price per Unit - Variable Cost per Unit)

- Helpful in pricing strategies and financial planning.

Net Present Value (NPV)

- Measures profitability of investments considering time value of money.

- NPV = ∑Ct(1+r)t\sum \frac{C_t}{(1 + r)^t} where CtC_t is cash flow in period tt and rr is discount rate.

Target Costing

- A pricing strategy where market price determines the cost structure.

- Target Cost = Market Price - Desired Profit.

- Encourages cost-efficient production and competitive pricing.

Process and Process Management

- A process is a sequence of activities transforming inputs into outputs.

- Process management involves optimizing workflows to enhance efficiency and quality.

- Types include manufacturing, service, and hybrid.

Product-Process Matrix

- Classifies processes based on volume and variety.

- Includes project (high customization, low volume), job shop (small batches, high variety), batch (moderate volume and variety), repetitive (standardized production), and continuous (high volume, low variety).

Capacity Planning

- Determines the production capability needed to meet demand.

- Strategies include lead (ahead of demand), lag (reactive), and match (gradual adjustment).

Theory of Constraints (TOC)

- Identifies and mitigates bottlenecks to improve efficiency.

- The five steps are identify constraint, exploit constraint, subordinate other processes, elevate constraint, and repeat cycle.

Process Mapping

- A visual representation of workflow to identify inefficiencies.

- Common types include flowcharts, swimlane diagrams, and value stream maps.

Bottleneck Analysis

- Identifies process constraints to optimize production flow.

- Involves cycle time calculation and throughput analysis.

Lean & Lean Management

- Philosophy focused on eliminating waste and maximizing value.

- Core principles include value, value stream, flow, pull, and perfection.

Competitive Advantages of Lean

- Reduces costs, improves quality, enhances customer satisfaction.

- Leads to faster production cycles and operational flexibility.

Push vs. Pull System

- Push systems base production on forecasted demand.

- Pull systems drive production by actual customer demand.

- Lean favors pull systems to minimize waste.

Key Japanese Terms

- Kaizen refers to continuous improvement.

- Kanban is visual inventory management.

- Muda means waste elimination.

- Heijunka is production leveling.

- Jidoka is automation with human intelligence.

Building Blocks of Lean

- Inventory Management: Reducing excess stock.

- Continuous Improvement: Incremental process optimization.

- SMED (Single Minute Exchange of Dies): Reducing setup times.

- TQM (Total Quality Management): Focused on quality at all levels.

- Cycle Time Reduction: Enhancing speed of production.

- Parallel Processing: Performing tasks simultaneously.

- Multi-function Workers: Employees trained in multiple skills.

- Work Environment Optimization: 5S implementation.

- Root Cause Analysis: Identifying and addressing fundamental issues.

Value Stream Mapping

- Analyzes material and information flow to enhance efficiency.

- Identifies non-value-added activities for elimination.

5S & 8 Wastes

- 5S: Sort, Set in Order, Shine, Standardize, Sustain.

- 8 Wastes: Defects, Overproduction, Waiting, Non-utilized Talent, Transportation, Inventory, Motion, Extra Processing.

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.