Podcast

Questions and Answers

What is the main topic of Unit 3 in the Applied Sciences course at Antwerp Maritime Academy?

What is the main topic of Unit 3 in the Applied Sciences course at Antwerp Maritime Academy?

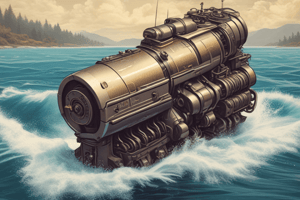

Propulsion

Which of the following is NOT a fuel type discussed for marine engines?

Which of the following is NOT a fuel type discussed for marine engines?

- Coal (correct)

- Hydrogen

- Electric

- Ammonia

The Lubrication oil system for marine engines includes a Main lubrication oil system.

The Lubrication oil system for marine engines includes a Main lubrication oil system.

True (A)

The connection between piston and ______ can be achieved through a Crosshead engine or a Trunk piston engine.

The connection between piston and ______ can be achieved through a Crosshead engine or a Trunk piston engine.

What parts of the engine are lubricated by the main lubrication system?

What parts of the engine are lubricated by the main lubrication system?

What are the different sections the lubrication oil system is split into?

What are the different sections the lubrication oil system is split into?

The high temperature fresh water system is used to cool down the engine cylinders and exhaust valves.

The high temperature fresh water system is used to cool down the engine cylinders and exhaust valves.

The low temperature fresh water system cools down different parts of the installation, such as the _____ and the turbo.

The low temperature fresh water system cools down different parts of the installation, such as the _____ and the turbo.

What is the purpose of the safety valve in a marine diesel engine?

What is the purpose of the safety valve in a marine diesel engine?

What component of a diesel engine transforms the piston's translation into rotation?

What component of a diesel engine transforms the piston's translation into rotation?

A turbocharger in a diesel engine is powered by the combustion of fuel.

A turbocharger in a diesel engine is powered by the combustion of fuel.

The distance traveled by the piston between the Top Dead Centre (TDC) and Bottom Dead Centre (BDC) is known as the _______ length.

The distance traveled by the piston between the Top Dead Centre (TDC) and Bottom Dead Centre (BDC) is known as the _______ length.

What is the residuum from the thermal cracking process that cannot be used as fuel but is used in asphalt and membrane roofing?

What is the residuum from the thermal cracking process that cannot be used as fuel but is used in asphalt and membrane roofing?

Which of the following statements about LPG is true?

Which of the following statements about LPG is true?

Methane has a higher knock resistance compared to hydrogen.

Methane has a higher knock resistance compared to hydrogen.

In the crosshead engine, the piston is _ connected with the piston rod, a crosshead supports and the connecting rod.

In the crosshead engine, the piston is _ connected with the piston rod, a crosshead supports and the connecting rod.

Match the alternative marine fuel with its description:

Match the alternative marine fuel with its description:

What is the primary purpose of the turbine in the propulsion system?

What is the primary purpose of the turbine in the propulsion system?

What is the purpose of the PTI (Power Take In) in the turbine system?

What is the purpose of the PTI (Power Take In) in the turbine system?

Exhaust gases should have a temperature above 200°C to prevent soot in the boiler.

Exhaust gases should have a temperature above 200°C to prevent soot in the boiler.

What is the purpose of electric accumulators in the emergency system? Electric accumulators start the emergency system in ___ conditions.

What is the purpose of electric accumulators in the emergency system? Electric accumulators start the emergency system in ___ conditions.

Match the component of the boiler with its description:

Match the component of the boiler with its description:

What is the purpose of controlling the viscosity of the fuel in a crosshead engine with an exhaust valve?

What is the purpose of controlling the viscosity of the fuel in a crosshead engine with an exhaust valve?

A vessel equipped with two daily tanks for heavy fuel can run every day on a single tank.

A vessel equipped with two daily tanks for heavy fuel can run every day on a single tank.

What is used to start the engine in a crosshead engine with an exhaust valve?

What is used to start the engine in a crosshead engine with an exhaust valve?

At what minimal pressure is the compressed air produced for starting the engine?

At what minimal pressure is the compressed air produced for starting the engine?

Match the following engine components with their functions:

Match the following engine components with their functions:

What transformation occurs in the superheater?

What transformation occurs in the superheater?

Fire tube boilers are used to generate saturated steam for heating purposes. (True/False)

Fire tube boilers are used to generate saturated steam for heating purposes. (True/False)

What is the primary purpose of a water tube boiler?

What is the primary purpose of a water tube boiler?

The flow rate of the supply pump is controlled with the rotational speed of the pump or with a control valve and directed with a signal indicating the water level in the _______ collector.

The flow rate of the supply pump is controlled with the rotational speed of the pump or with a control valve and directed with a signal indicating the water level in the _______ collector.

What is the rotational speed range of a turbine as mentioned in the content?

What is the rotational speed range of a turbine as mentioned in the content?

What is the main purpose of a turbine in driving most rotating machines?

What is the main purpose of a turbine in driving most rotating machines?

Which is NOT a characteristic of isentropic expansion?

Which is NOT a characteristic of isentropic expansion?

A turbine seal must be contactless due to the high rotational speeds involved.

A turbine seal must be contactless due to the high rotational speeds involved.

The turbines are positioned to compensate the axial forces by another turbine if a system exists out of more than one ____________.

The turbines are positioned to compensate the axial forces by another turbine if a system exists out of more than one ____________.

What are the two turbines used for propulsion?

What are the two turbines used for propulsion?

What is the purpose of sending the lowest possible amount of steam to the condenser?

What is the purpose of sending the lowest possible amount of steam to the condenser?

What type of turbines are the turbo alternators described in the text?

What type of turbines are the turbo alternators described in the text?

What is the purpose of the secondary steam system mentioned in the text?

What is the purpose of the secondary steam system mentioned in the text?

Why is the secondary steam system separated from the primary system?

Why is the secondary steam system separated from the primary system?

What is the purpose of the steam-steam generator mentioned in the text?

What is the purpose of the steam-steam generator mentioned in the text?

Flashcards are hidden until you start studying

Study Notes

Propulsion I

- The course Propulsion I aims to describe the entire drive train of a merchant vessel, starting from the properties of marine fuel and how it is refined, to the engine and propeller.

Diesel Engine

- A marine diesel engine is composed of a number of cylinders, with a cylinder liner made of cast iron, rigidly connected to the engine block.

- The cylinder liner is at the top side closed with the cylinder cover, which contains fuel injectors, safety valves, starting air valves, inlet valves, and exhaust valves.

- A piston moves up and down in the cylinder, made gas-tight by three to five piston rings.

- The continuous translation of the piston takes place between the Top Dead Centre (TDC) and the Bottom Dead Centre (BDC).

- The distance traveled by the piston in one motion is known as the stroke or stroke length.

- The translation of the piston is transformed into a rotation by a connection rod – crank system.

Engine Cycles

- A four-stroke engine has four cycles: compression, power, exhaust, and intake.

- A two-stroke engine has two cycles: compression and power, with scavenging occurring at the end of the power stroke.

- Two types of scavenging can be distinguished: uniflow-scavenged and loop-scavenged.

Comparison between 2 Stroke and 4 Stroke Engine

- A two-stroke engine can deliver more power than a four-stroke engine for the same engine speed and dimensions.

- A two-stroke engine produces power every rotation, while a four-stroke engine needs two rotations for one power stroke.

- A two-stroke engine can use ports, while a four-stroke engine uses valves.

Fuel

- Atmospheric distillation, vacuum distillation, catalytic cracking, and thermal cracking are methods of refining fuel.

- LPG, LNG, and CNG are alternative marine fuels.

- Knock resistance is a key factor in fuel selection.

The Connection between Piston and Crankshaft

- The connection between the piston and crankshaft can be done using a crosshead engine or a trunk piston engine.

- Crosshead engines have a piston rod attached to a crosshead, which makes a vertical translation, allowing for a stuffing box to separate the chambers.

- Trunk piston engines have a piston attached directly to the crankshaft.

The Different Systems

- The lubrication oil system, cooling water system, fuel oil system, and starting procedure are essential systems in a diesel engine.

- The lubrication oil system includes lubrication of the cylinder liner, camshaft, and main lubrication oil system.

- The cooling water system includes high temperature fresh water system, low temperature fresh water system, seawater system, and piston cooling water system.

- The fuel oil system includes storage, settling, and service tanks, as well as supply of fuel to the injection pumps.

Diesel Generators

- Diesel generators are used as emergency systems or auxiliaries.

- They are used to provide power in case of main engine failure or when the ship is at anchor.

Steam Turbine

- The steam turbine is a type of engine that uses steam to generate power.

- The steam turbine is connected to a generator to produce electricity.

- The steam turbine has a geometry that allows for efficient energy conversion.

- The turbine steam condenser is used to cool the steam and convert it back into liquid.

- The turbine bearings and seal are essential components of the steam turbine.

Steam Boiler

- The steam boiler is a critical component of the steam turbine system.

- The boiler is used to produce steam, which is then used to generate power.

- The boiler includes components such as the economiser, evaporator, and superheater.

- The boiler is classified into two types: fire tube boiler and water tube boiler.

- The boiler is equipped with safety valves, supply pumps, and desuperheater.

Examples

- The LNG carrier Methania is an example of a steam system with a turbine.

- The steam system is used to generate power for the ship's propulsion.### Fuel Refining Process

- The refining process is necessary to understand the nuances of fuel quality

- Four main steps in the refining process:

- Atmospheric distillation

- Vacuum distillation

- Catalytic cracking

- Thermal cracking

Atmospheric Distillation

- Crude oil is heated to 360°C at atmospheric pressure

- Lighter components vaporize and rise in the column

- Temperature decreases higher in the column

- Different levels of the column yield different qualities of fuel

- Top of the column: LPG (Methane, Propane, Butane) and gases with a boiling point below 125°C

- Lower in the column: atmospheric distillates (benzene, naphtha, kerosene, gasoil)

- Bottom of the column: atmospheric residuum (70-90% of the original crude oil)

Vacuum Distillation

- Temperature limited to 400°C to prevent cracking

- Vacuum simplifies vaporization and yields more fuel

- Outcomes: vacuum gasoil and slop wax

- Vacuum gasoil is used as gasoil after dilution with atmospheric distillate

- Slop wax is used as raw material for catalytic cracking

Catalytic Cracking

- Slop wax is treated to crack long molecules into shorter ones

- Process carried out at high temperatures (250°C) with aluminosilicates

- Outcomes: LPG, gasoil, olefins (ethylene), and unsaturated compounds

- Hydrogenation adds H to unsaturated compounds for stability

Thermal Cracking

- Final step to extract fuels and chemicals from residuum

- Two types: visbreaker and flexicoker

- Visbreaker: yields a small amount of LPG and distillates

- Flexicoker: yields more distillates and a more stable residuum

Concluding Remarks on Refining

- Different refining processes yield different fuel properties

- Residual fuel is a mixture of residuum and can be diluted with distillates

- Cracking makes residuum less stable, and catalytic cracking yields catalytic fines

Alternative Marine Fuels

- Hydrogen:

- Hard to store due to high pressure and low temperature

- Origin can be "brown" or "green"

- Produces water after combustion

- Methanol and Ethanol:

- Can be made from CO2 and H2

- Produce CO2 and H2O after combustion

- Fluid and easy to store

- Methane and Ethane:

- Methane slip

- Greenhouse gas

- Ammonia:

- Zero carbon

- Toxic and corrosive

- Fluid

- Electric:

- Storage (battery) is problematic

- Simple, reliable, and low maintenance

- Torque and autonomy

Connection between Piston and Crankshaft

- Crosshead Engine:

- Principle: piston is connected to piston rod and crosshead, which supports the connecting rod and crankshaft

- Consequences:

- Large and heavy pistons

- Limited rotational speed

- Reliability increases

- Specific fuel consumption is better

- Applications: large two-stroke engines for propulsion

- Issues: lubrication, scavenging, and cooling

- Trunk Piston Engine:

- Principle: connection rod connects piston and crankshaft directly

- Consequences:

- Smaller pistons

- Higher rotational speed

- More power per cylinder

- Four-stroke engine is more suitable

- Applications: smaller engines for gensets, RoRo-vessels, and high-speed vessels

- Issues: maintenance cost, reliability, and fuel quality

Lubrication Oil System

- Lubrication of the cylinder liner:

- Obtained by injecting lube oil between cylinder segments

- System includes storage tank, make-up tank, lubrication pump, and lubricators

- Lubrication of the camshaft:

- Dedicated system sometimes used

- Main system used as standard

- Main lubrication oil system:

- Provides lubrication oil to crankshaft, gears, connection rod, and crosshead

- Cools the piston

- System includes service tank, cooling system, and filters

Cooling Water System

- High-temperature fresh water system (HTFW):

- Cools engine, cylinders, and cylinder covers

- Temperature of the water needs to be warm enough

- May be cooled by mixing with low-temperature fresh water system or heat exchangers

- Low-temperature fresh water system (LTFW):

- Cools the HTFW system, lubrication systems, and other components

- Temperature of the water is around 32°C

- Can be cooled by seawater system via heat exchangers

- Seawater system:

- Cools the LTFW system

- Two concepts: decentralized and centralized seawater cooling systems### Cooling Systems

- Various parts of the engine require low temperatures, which are achieved by directly connecting them to the seawater system (e.g., air conditioning, refrigerators, steam condenser)

- More fragile or temperature-sensitive parts are cooled with a centralised cooling system

- There are three types of cooling systems:

- Seawater cools freshwater, which in turn cools lube oil, exhaust gases, and the engine (jacket)

- Seawater cools exhaust gases and freshwater, which then cools lube oil and the engine

- Seawater cools lube oil, exhaust gases, and freshwater, which then cools the engine

MAN Cooling System

- The MAN system is a centralised cooling system that cools:

- LTFW (Low Temperature Fresh Water)

- Air-conditioning

- Steam condenser

- Condenser and oil cooling system of the cooling installation

- The system has two main pumps and one auxiliary pump, with the auxiliary pump used in harbour conditions

- There are two seawater chests: one at the bilge and one at a higher position

SULZER Cooling System

- The SULZER system is similar to the MAN system

- It is used to replace the LTFW if there is no centralised cooling system

- The control of the temperature of the seawater is important

Piston Cooling Water System

- Sometimes, pistons are cooled with water, which requires a dedicated cooling water system

- The system is used only for large engines and has a high risk of corrosion due to the presence of air

Fuel Oil System

- Overview of the fuel oil system:

- Storage tanks (1) with fuel at 30-50°C to be pumpable

- Settling tank (2) with fuel at 70°C to remove impurities

- Daily tank (or service tank) (3) with clean fuel

- Fuel is cleaned in purifiers before entering the daily tank

- Fuel pumps are sometimes incorporated into the purifiers

- Switching fuel type (e.g., from heavy fuel oil to diesel oil) requires carefulmanagement of viscosity and temperature to avoid damage to the engine

High-Pressure Injection

- Fuel is injected into the cylinder through injectors

- The fuel is atomized, resulting in smooth self-ignition and integral combustion

- The injection pump is specific to each cylinder

- The pressure in the injection pipes is about 600-1500 bar, depending on the injection speed, nozzle dimensions, and fuel viscosity

- The viscosity of the fuel is monitored and controlled to ensure proper injection

Starting Procedure for the Main Engine

- Production of compressed air:

- Compressed air is produced with two compressors with different stages and intercooling

- Both compressors are connected in parallel and start automatically when the compressed air pressure drops below a minimal pressure

- The compressed air is cooled before being stored, and condensation of the air cannot be avoided

- Switching the engine on:

- Compressed air enters the cylinder at the same time as the piston reaches the position where combustion is expected

- The starting valves are opened pneumatically with a starting air valve

- Minimal number of cylinders to start an engine:

- For a two-stroke engine, at least 4 cylinders are necessary

- For a four-stroke engine, at least 6 cylinders are necessary

- Failed engine start:

- The engine may not start due to various reasons, such as sedimentation of soot in the starting valves

- A slow start procedure is used to avoid this issue

- Slow start:

- A second master valve with a small air capacity allows the engine to run slowly without fuel supply

- This is used to check the performance of all parts and to drain fluids collected in the cylinder

- Changing the direction of the engine:

- The engine must be able to run in both directions

- The camshaft, valves, and fuel cams must be repositioned

- A hydraulic servomotor is used to shift the camshaft

Protection

- The engine is equipped with different types of protection systems:

- The master valve cannot be opened while the 'torn machine' of the engine is active

- The master valve cannot be opened as long as the starting cams are not in the correct position

- Compressed air cannot enter the cylinder as long as the cylinder pressure is too high or the rotational speed of the engine is too high

- Fuel oil cannot be injected as long as the direction of the engine is in the desired rotational direction

Turbocharger

- A turbocharger consists of a turbine and a compressor

- The turbine is driven by exhaust gases and compresses air

- The compressed air is used for scavenging and combustion in the cylinders

- The amount of air available for combustion is the limiting factor for the amount of fuel injected in the cylinder and the total power of the engine

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.