Podcast

Questions and Answers

What is the typical temperature range used in moist heat sterilization?

What is the typical temperature range used in moist heat sterilization?

- 121-134°C (correct)

- 180-190°C

- 100-110°C

- 150-160°C

What is the equipment used for moist heat sterilization called?

What is the equipment used for moist heat sterilization called?

- Furnace

- Steamer

- Autoclave (correct)

- Oven

What is the advantage of using high temperature-short time cycles in autoclaving?

What is the advantage of using high temperature-short time cycles in autoclaving?

- Lower levels of sterility assurance and higher fractional degradation of the product

- Higher levels of sterility assurance and lower fractional degradation of the product (correct)

- Lower levels of sterility assurance

- Higher fractional degradation of the product

What type of steam is most effective for sterilization?

What type of steam is most effective for sterilization?

What is the primary mechanism of heat transfer in steam sterilization?

What is the primary mechanism of heat transfer in steam sterilization?

What is the typical duration of sterilization at 121°C?

What is the typical duration of sterilization at 121°C?

What is the primary advantage of using steam in sterilization?

What is the primary advantage of using steam in sterilization?

What is the purpose of the phase boundary in steam sterilization?

What is the purpose of the phase boundary in steam sterilization?

What is the purpose of a fan inside the autoclave?

What is the purpose of a fan inside the autoclave?

During the sterilization stage, what occurs in addition to the holding time?

During the sterilization stage, what occurs in addition to the holding time?

How is rapid evaporation of water achieved during the drying stage?

How is rapid evaporation of water achieved during the drying stage?

What is the purpose of circulating water in the jacket during the cooling stage?

What is the purpose of circulating water in the jacket during the cooling stage?

Why is the introduction of filtered compressed air necessary at the end of autoclaving?

Why is the introduction of filtered compressed air necessary at the end of autoclaving?

What happens when the temperature of 'dry' saturated steam is increased above the phase boundary?

What happens when the temperature of 'dry' saturated steam is increased above the phase boundary?

What can cause superheated steam to occur?

What can cause superheated steam to occur?

Why is it important to remove air from the steam during autoclaving?

Why is it important to remove air from the steam during autoclaving?

What is the purpose of the vent during air removal and steam admission?

What is the purpose of the vent during air removal and steam admission?

What is the benefit of using vacuum along with steam admission during air removal?

What is the benefit of using vacuum along with steam admission during air removal?

Why is it important to organize items properly inside the autoclave?

Why is it important to organize items properly inside the autoclave?

Why is residual air intentionally left inside the autoclave when sterilizing fluids in flexible plastic bottles?

Why is residual air intentionally left inside the autoclave when sterilizing fluids in flexible plastic bottles?

What is the final stage of the autoclaving operation?

What is the final stage of the autoclaving operation?

Flashcards are hidden until you start studying

Study Notes

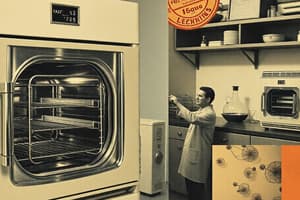

Moist Heat Sterilization

- Involves the use of steam at temperatures between 121°C and 134°C for a certain duration

- Equipment used is called an Autoclave or Steam Sterilizer

- Widely used to sterilize:

- Culture media

- Thermostable products and devices (dressings, sheets, surgical and diagnostic equipment, containers, and closures)

- Aqueous injections and irrigation fluids

- Contaminated items and waste

Principle of Moist Heat Sterilization (Autoclaving)

- Steam provides moisture and heat efficiently to the article to be sterilized

- Saturated steam is used, which is steam in thermal equilibrium with the water from which it is derived

- Advantages of steam:

- Excellent medium for heat transfer

- High latent heat

- High penetration power

- Uniform temperature

- Rapid heating up of objects

Process of Autoclaving

- 3 stages:

- Heating-up and exposure

- Sterilizer reaches operating temperature and pressure, and sterilization begins

- Duration of exposure includes heating-up time and holding time 2. Drying or cooling:

- Dressings and porous loads may become dampened during sterilization and must be dried

- Steam release from air vent, vacuum, and heat from steam-filled jacket 3. Cooling (for bottled fluids):

- Rapid cooling is necessary to minimize thermal degradation

- Achieved by circulating water in the jacket or spray-cooling with water

Superheated Steam

- Occurs when temperature of 'dry' saturated steam is increased above the phase boundary

- Relative humidity or degree of saturation is reduced, and steam becomes superheated

- Sources of superheated steam:

- Overheating the steam jacket

- Using too dry a steam supply

- Presence of air

- Superheated steam behaves like hot air, with no condensation or release of latent heat

- Must be avoided

Importance of Air Removal

- Presence of air in the steam must be avoided because:

- Causes superheating

- Sterilizing temperature may not be reached, and heating-up period gets longer

- More heat is required to reach the same temperature, making it less economic

- Addition of further steam will raise the temperature, but residual air surrounding articles may delay heat penetration

Stages of Autoclaving Operation

- 3 stages:

- Air removal and steam admission

- Heating-up and exposure

- Drying or cooling

Studying That Suits You

Use AI to generate personalized quizzes and flashcards to suit your learning preferences.