Podcast

Questions and Answers

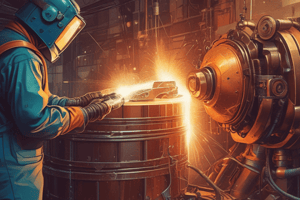

What are welding defects?

What are welding defects?

- Irregularities formed in the given weld metal due to wrong welding process or incorrect welding patterns (correct)

- Irregularities formed due to the use of incorrect welding materials

- Irregularities formed due to excessive heat in the welding process

- Irregularities formed due to the lack of protective gear during welding

What are porosity and blowholes in welding?

What are porosity and blowholes in welding?

- Porosity is a result of excessive heat, while blowholes are a result of weld metal contamination

- Porosity is a result of weld metal contamination, while blowholes are caused by excessive heat

- Porosity is caused by trapped gases, while blowholes are a group of small bubbles (correct)

- Porosity is caused by incorrect welding patterns, while blowholes are caused by trapped gases

What is undercut in welding?

What is undercut in welding?

- Formation of cracks on the surface of the weld metal

- Formation of excessive heat around the weld area

- Formation of excess material around the weld area

- Formation of grooves in the weld toe, which decreases the cross-sectional thickness of the base metal (correct)

What causes weld cracks?

What causes weld cracks?

Why are some welding defects never accepted?

Why are some welding defects never accepted?

Which type of welding defect occurs when there is a shortage of suitable fusion between the metal and weld?

Which type of welding defect occurs when there is a shortage of suitable fusion between the metal and weld?

What is the dangerous substance that appears as a product of stick welding, flux-core arc welding, and submerged arc welding?

What is the dangerous substance that appears as a product of stick welding, flux-core arc welding, and submerged arc welding?

What is defined as the distance from the uppermost surface of the base plate to the maximum extent of the weld nugget?

What is defined as the distance from the uppermost surface of the base plate to the maximum extent of the weld nugget?

What are tiny metal particles ejected from the arc during welding and accumulate on the base metal throughout the weld bead along its length?

What are tiny metal particles ejected from the arc during welding and accumulate on the base metal throughout the weld bead along its length?

What type of welding defect occurs when the deposited metal starts to develop cracks from the nearby edge and solidify as the crack increases?

What type of welding defect occurs when the deposited metal starts to develop cracks from the nearby edge and solidify as the crack increases?

What is the dangerous substance that appears as a product of stick welding, flux-core arc welding, and submerged arc welding?

What is the dangerous substance that appears as a product of stick welding, flux-core arc welding, and submerged arc welding?

What type of welding defect occurs when the metal groove is not entirely filled, leading to the weld metal not fully spreading through the joint thickness?

What type of welding defect occurs when the metal groove is not entirely filled, leading to the weld metal not fully spreading through the joint thickness?

What is the difference in size and location between the positions of the two metal plates before and after welding due to the temperature gradient present at several points along the weld joints?

What is the difference in size and location between the positions of the two metal plates before and after welding due to the temperature gradient present at several points along the weld joints?